In recent years, the aerospace industry does not seem to have taken real strides. However, many companies have invested astronomical funds in research and development, hoping to create the next major achievement in the aerospace field. For this reason, the latest developments in 3D printing (also known as additive manufacturing) make it one of the most important technologies affecting the aerospace industry.

The satellite has become the main focus of scientists and engineers, it can be used for advanced research and more commercial uses, such as the global Internet system. However, these satellites need a way to get into orbit, and the best way is still to use rockets. But making rockets and sending payloads to space is a very expensive project. At present, minimizing the cost of manufacturing rockets has always been the goal of the industry. The key to achieving this is to make the rocket lighter, more fuel-efficient, and cheaper. This is where 3D printing comes in.

The main advantage of 3D printing in the rocket manufacturing business is that it can reduce the number of parts and make the production line flexible without the need to invest tens or even hundreds of millions of dollars in special tools before manufacturing each design. The rocket is composed of thousands of parts and is a very complex product. With 3D printing, the number of rocket parts can be greatly reduced, thereby reducing costs. In this way, we are entering a new era of cost-effective rocket manufacturing and space operations.

Let’s explore the latest and most exciting progress of the 3D printed rocket together.

Relativity Space: 3D print the whole rocket

Relativity Space is a company founded in 2015 with the goal of manufacturing the world’s first fully 3D printed rocket, called Terran 1. They use a 3D printer to reduce the number of rocket parts as much as possible and make the production of rockets a flexible process.

On average, a rocket has about 50,000 to 100,000 parts, which makes it as complex as a car. Relativity Space has successfully reduced the number of parts on the rocket to about 1,000, thereby greatly reducing costs.

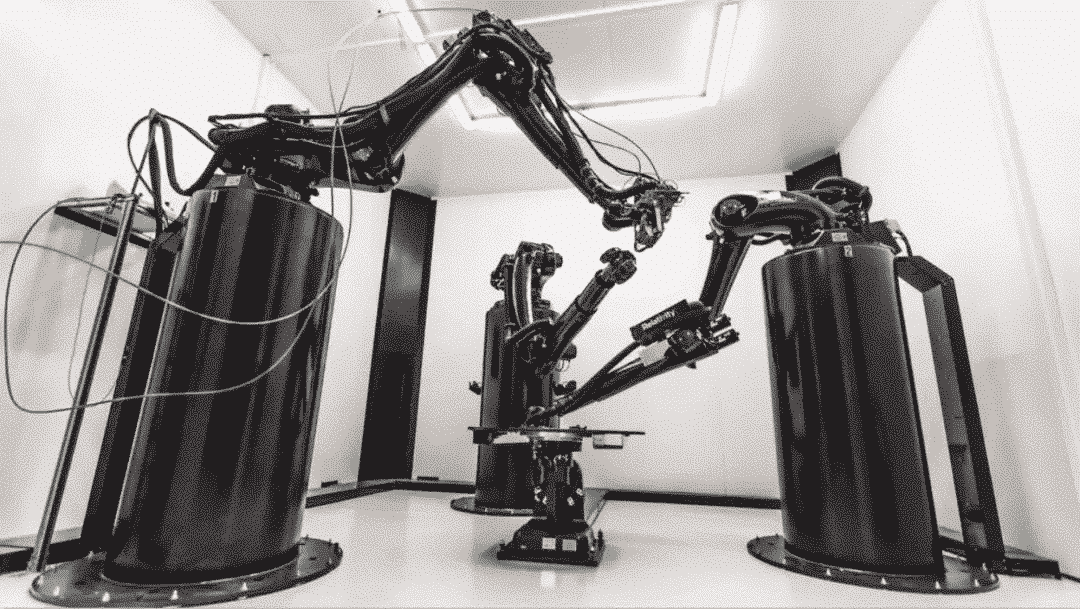

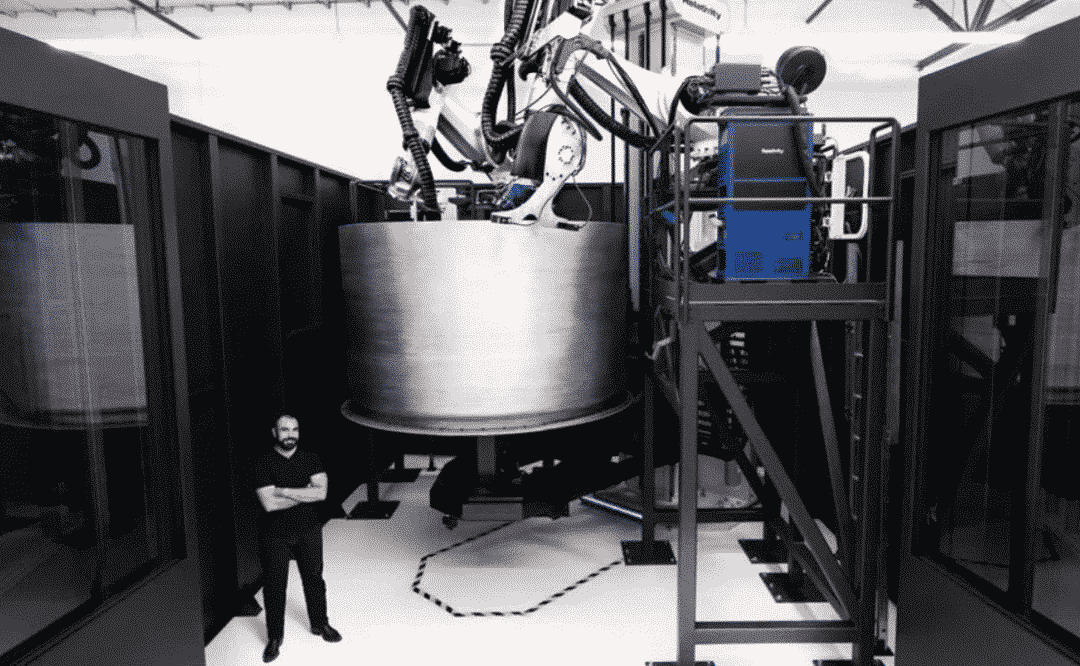

Since 3D printing seems to be the ideal manufacturing method, Relativity continues to develop its own 3D printer Stargate. It is one of the largest metal 3D printers in the world and is responsible for most of the production of Terran 1. The entire system consists of three robotic arms, one for printing and the other two for post-processing. The technique used is direct energy deposition(DED), in which the wire is fed into the melting zone and then extruded into the desired shape. In layman’s terms, basically 3D welding.

Relativity Space’s innovations don’t stop there, because they also invested in AI to monitor the production process, making it better and more efficient in every possible way. The Terran 1 rocket has a maximum payload of 1,250 kg and is powered by 9 Aeon 1 engines, which are 3D printed and use liquid methane and liquid oxygen as propellants.

The fuel tank is also 3D printed by the Stargate printer. From the outside, the tank looks like a simple structure, but in fact, it consists of two internal tanks, because each propellant needs to be stored separately. Due to the large volume of the Stargate printer, the tank can be printed in one piece without seams, so it is very safe and avoids potential leaks.

As claimed by the company’s website, their Stargate factory was able to print out Terran 1 within 60 days, taking it from the raw material all the way to the flying vehicle. In contrast, the lead time for conventional rocket manufacturing usually exceeds one year!

Stargate is responsible for manufacturing rocket structures and propellant fuel tanks, while smaller components and engines are printed on direct metal laser sintering (DMLS) 3D printers. The orbital test is scheduled for 2021, and the official launch of the commercial rocket should be conducted shortly thereafter.

Orbex: The world’s largest 3D printed rocket engine

Orbex is a UK-based startup specializing in the development of satellite launch vehicles. Orbex launched the environmentally friendly Rocket Prime, which is used to provide low-cost orbital launch services and has received extensive media coverage. Considering that Orbex was only 5 years old, this is an amazing achievement.

In order for Orbex to achieve the goal of low-cost orbital launch, it is very important to make light rockets with the best materials. Although most rockets are made of carbon fiber, aluminum, and graphene composite materials, 3D printing still plays a role in Orbex.

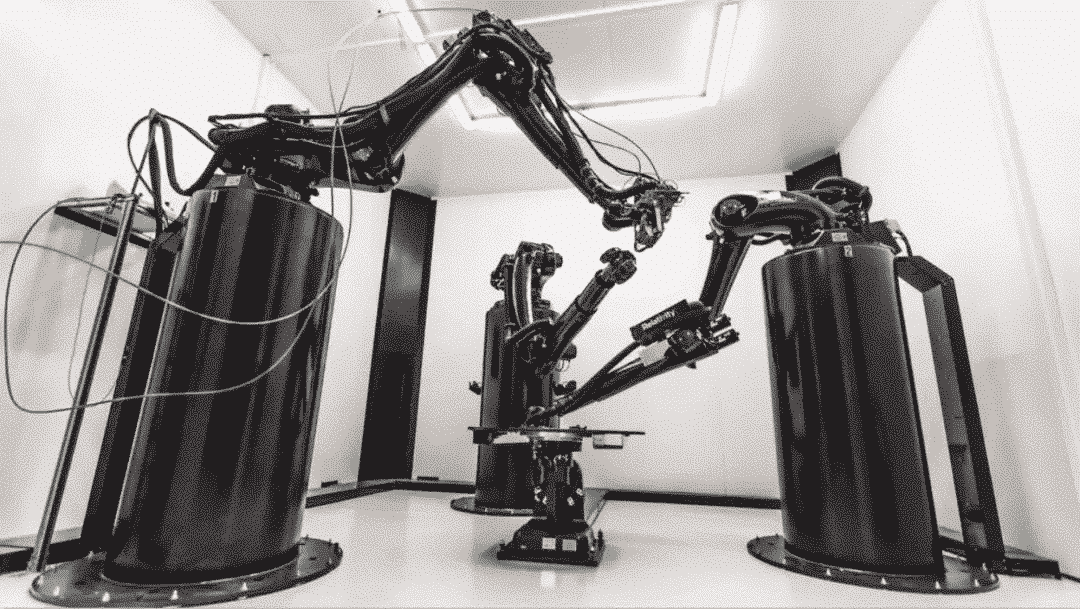

Orbex’s launch vehicle is powered by the world’s largest 3D printed rocket engine. It prints once on the SLM Solutions 800 machine without the need for extra connectors. It burns bio-propane fuel to ensure the lowest possible carbon emissions. Orbex’s vehicle will be launched for the first time in 2021.

Rocket Lab:Small satellite in low earth orbit

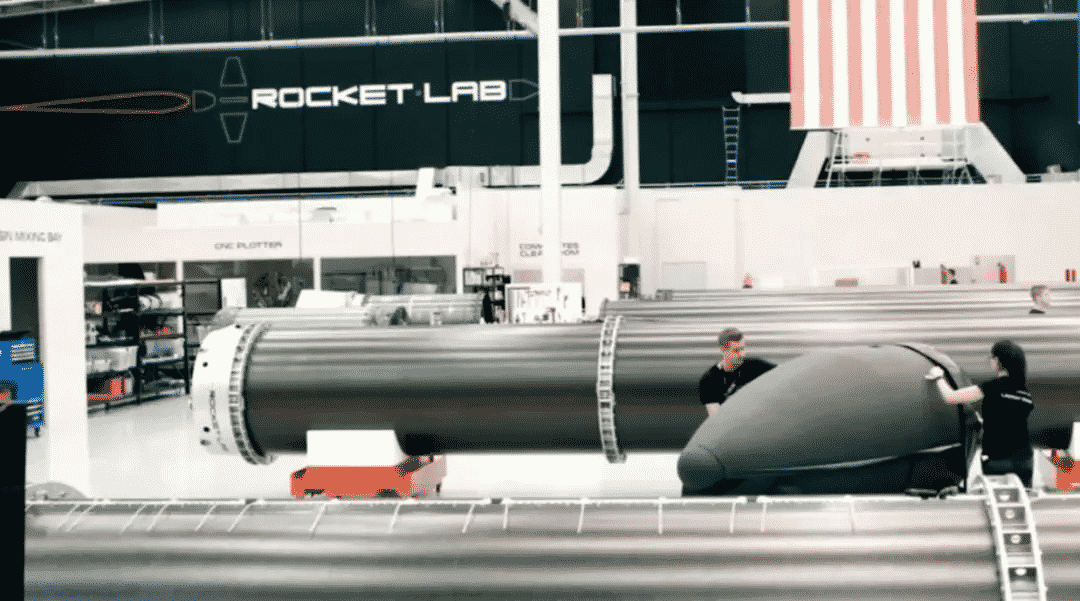

Rocket Lab is a California-based aerospace company dedicated to putting small satellites into low-Earth orbit. Recently, the company launched the new two-stage launch vehicle Electron. The rocket itself is made of carbon composite material to reduce weight as much as possible, with a maximum payload of 225 kg.

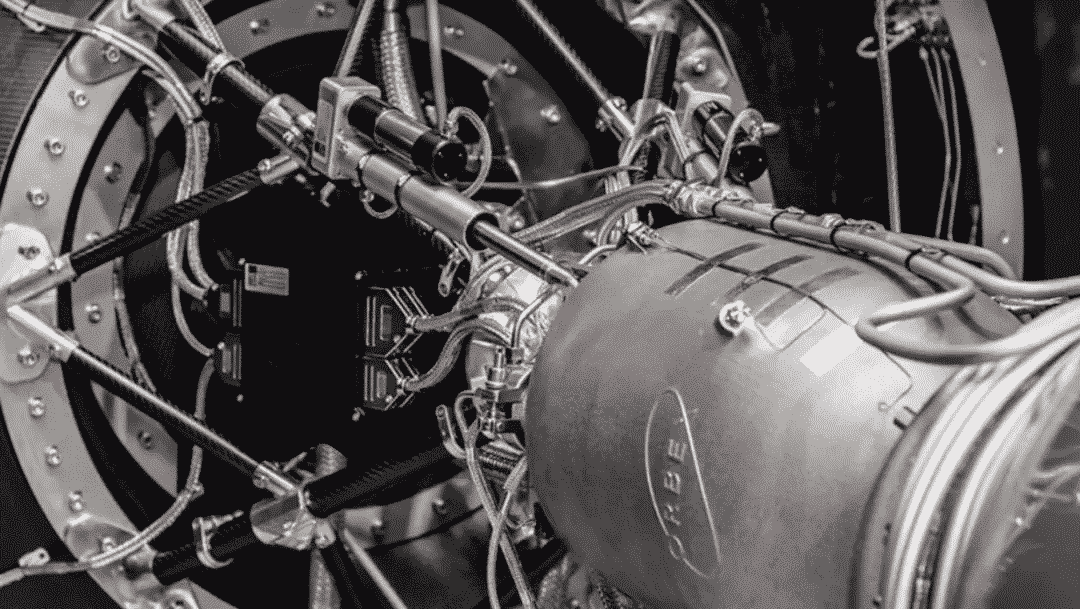

Rocket Lab is more interesting to use a special 3D printing Rutherford engine. What is the Rutherford engine? The Rutherford engine, named after Ernest Rutherford, is a small rocket engine that uses oxygen and kerosene as propellants. Combining a simple design that is easy to produce with a professional electron beam melting (EBM) 3D printer, an efficient cost reduction setup can be achieved.

So far, Rocket Lab has printed more than 100 such engines, and they have successfully completed various test procedures. The production process itself is impressive (this is unique to Rocket Lab), each rocket takes only 24 hours. It can be said that Rocket Lab is working hard to realize the vision of unleashing the potential of space.

Launcher:3D printed rocket efficient engine

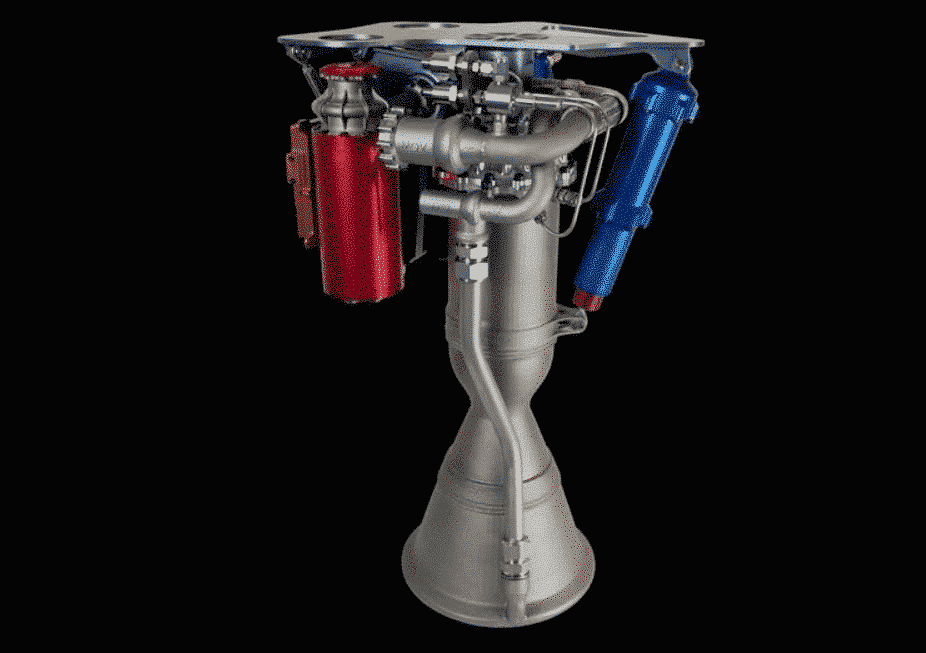

Launcher is a new company based in Brooklyn, dedicated to developing the world’s most efficient “small rockets” to put small satellites into orbit. Their solution is Rocket-1, which is a 20-meter-long rocket equipped with a set of 5 Engine-2 thrusters, with a maximum payload capacity of 773 kg.

In order to provide competitive prices for satellite launches, the production costs of rockets and engines must be as low as possible. By collaborating with EOS and AMCM, Launcher uses 3D printing in its workflow.

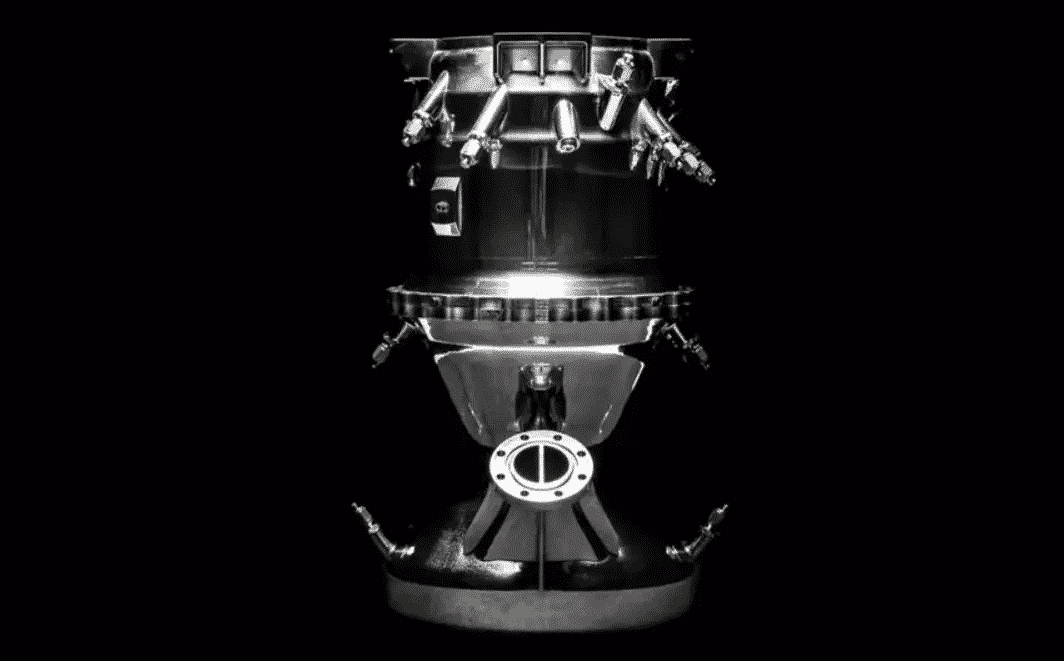

Engine-2 has the world’s largest all-in-one 3D printing combustion chamber, which is integrally formed by a copper alloy on an SLS 3D printer. Printing all parts at once makes production easy because no seams exist. This also enabled them to develop propellers with efficiencies as high as 98%, which is a remarkable achievement. The engine uses kerosene and liquid oxygen as propellants, and it is expected to provide 22,000 pounds (about 97,860 Newtons) of strong thrust.

Skyrora: From plastic waste to propellant

Skyrora is an Edinburgh-based company that focuses on satellite launches. It caught our attention with its innovative fuel method. Skyrora managed to find a way to develop fuel, especially kerosene, from plastic waste. They call it “eicosene”, and the gas emissions generated during combustion are reduced by about 45%.

Skyrora’s process of extracting fuel from plastic waste has attracted widespread attention in the aerospace industry. And the process is said to be able to produce 600 kg of kerosene from 1,000 kg of plastic waste in 24 hours.

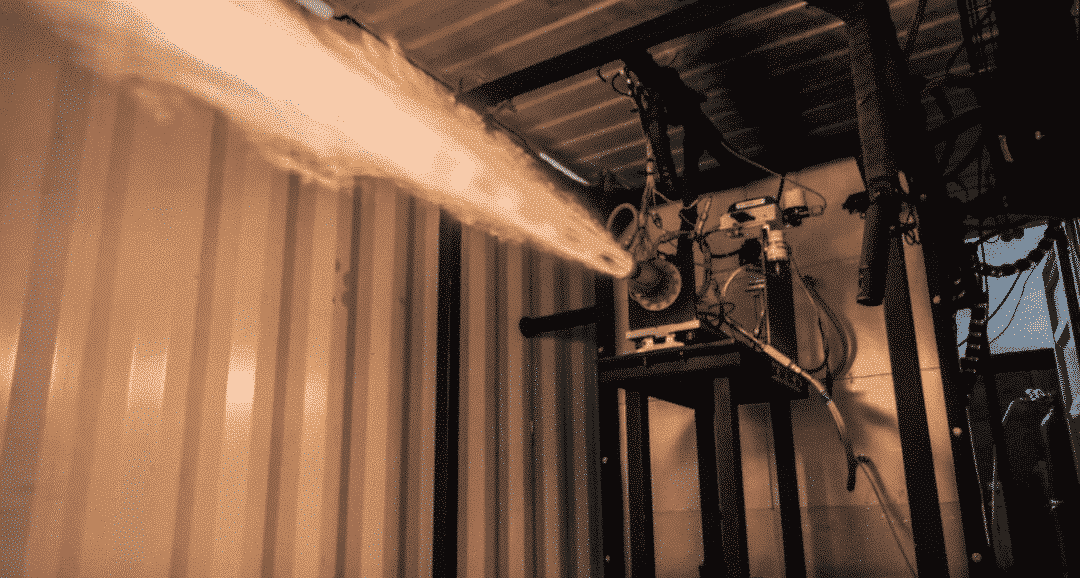

Skyrora developed this fuel to power its 3.5 kN 3D printing engine system Leo, which is expected to find its use in the Skyrora XL rocket, which is 22 meters long. The 3D printing engine system can also be used to maneuver the rocket after it reaches orbit, because it has an innovative function of restarting.