A team of interdisciplinary researchers at KU Leuven University have taken a step closer to being able to regrow teeth from the root using 3D printing.

Dental conditions resulting from trauma and developmental anomalies can often affect developing permanent teeth, particularly in children, leading to tissue or even whole tooth loss. To combat this, dental tissue engineering has arisen as a potential means of repair, regeneration, and even tooth replacement through the fabrication of bioengineered “tooth-root”.

In their latest study, the team investigated the 3D printing of chitosan scaffolds derived from animal and fungal sources which could potentially be used in such regenerative dentistry applications in the future.

3D printing and regenerative medicine

The role of 3D printing within regenerative medicine is very much still in its nascent stage, although there have been several promising developments in this area recently.

Starting with human tissue bioprinting breakthroughs, scientists from the University of Buffalo have developed a rapid new 3D bioprinting method slated to bring fully-printed human organs closer to reality, while researchers from Lund University have developed a new 3D printable bioink derived from seaweed and lung tissue that can be used to print constructs resembling human-sized airways capable of supporting cell and blood vessel growth.

3D printer OEM 3D Systems also recently announced a breakthrough in its Print to Perfusion bioprinting platform, which is now able to rapidly produce full-size, vascularized lung scaffolds. As a result, the firm is planning to ramp up its regenerative medicine activities going forwards.

Most recently, Penn State researchers unveiled a 3D bioprinting process capable of printing hard and soft tissue simultaneously to repair skin and bone injuries in a single procedure.

Despite sizeable strides taken in 3D printing for dental applications such as customized aligners, permanent crowns, and dental implants, regenerative medicine developments for dental applications have seen less focus. However, tissue engineering and regenerative medicine have recently been explored for the replacement of injured and missing dental tissues with promising results, such as for regenerative endodontic procedures.

These procedures aim to repair or replace the inflamed or damaged dental pulp – the part in the center of a tooth made up of living connective tissue and cells – in order to restore vascularization, immune response, nerve supply and dentin disposition, which refers to the largest structural component of a tooth that provides support to the enamel.

3D printing the chitosan scaffolds

Manufacturing on Demand

According to the researchers, chitosan has attracted attention for dental tissue engineering applications due to its antimicrobial and immunomodulatory properties, in addition to its biocompatibility, biodegradability, and gel-forming ability. Chitosan is derived in part from the exoskeleton of crustaceans such as crabs and shrimps, fungi, or insects.

Two types of chitosan were selected for this particular study; chitosan of animal origin and fungal chitosan derived from aspergillus niger, a common species of fungus that causes black mold. Gelatine powder was used as an additional polymer, while genipin and 3-glycidyloxypropyl trimethoxysilane (GPTMS) were used as cross-linking agents.

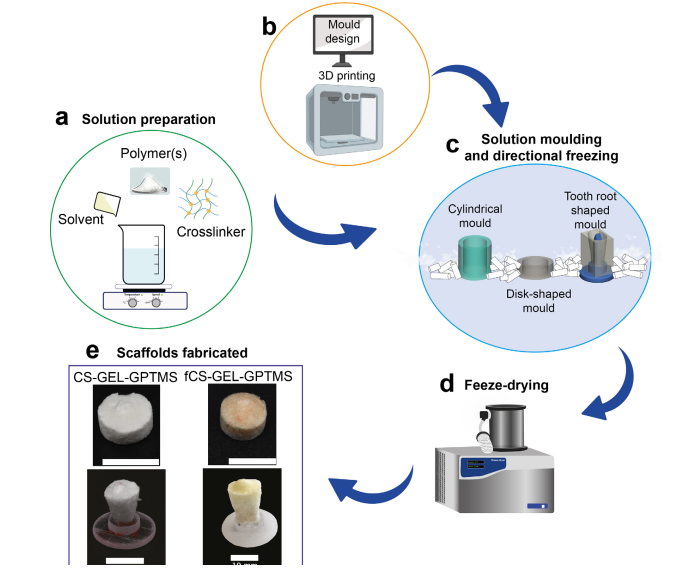

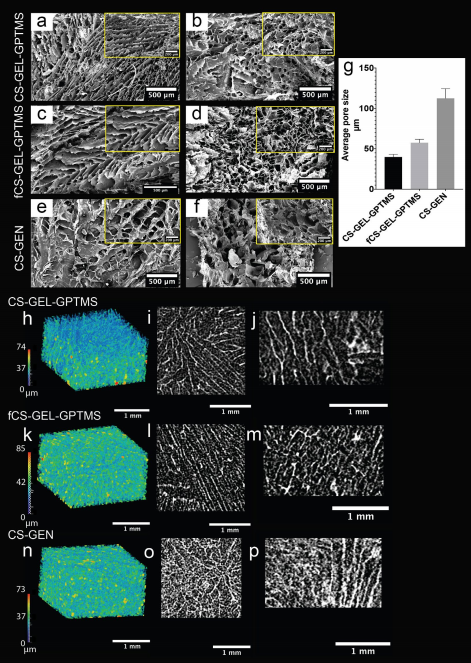

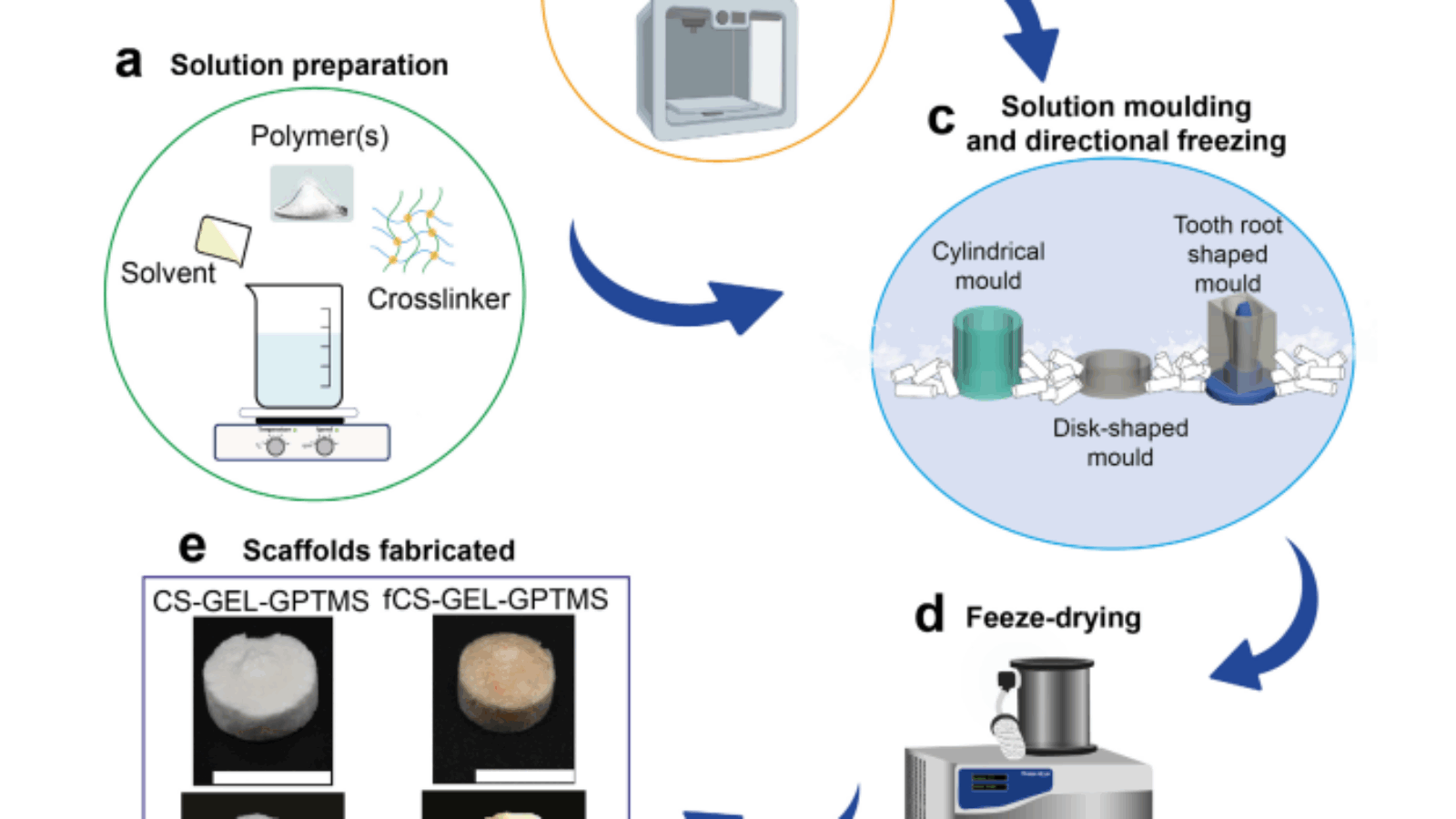

The chitosan-based scaffolds were prepared via an emulsion freeze-drying technique which involved the design of suitably-sized molds using CAD software and which were then printed using a polyjet 3D printer. The polymer solutions were then prepared and dispensed in the molds before being immediately placed in dry ice for directional freezing to achieve a radially oriented pore structure.

The molds were then freeze-dried for 24 hours and demolded to obtain the final scaffolds. While basic molds were printed this time around, 3D printing allows for the design and production of patient and tooth-specific molds, and therefore scaffolds.

The fungal-derived chitosan scaffold in particular was explored for its desirable properties of reduced risk of allergic reaction, low molecular weight, and enhanced antimicrobial properties.

More generally, the scaffolds were investigated for their direct clinical application in cell-free regenerative endodontics of immature teeth to control infections, induce dentine formation and root formation.

The researchers also believe their tailored scaffolds could be modified through adding inorganic components such as bioactive glass to promote alveolar bone regeneration. Alveolar bone is the thick ridge of bone that contains the tooth sockets, located on a person’s jaw bones.

Going forwards, the team will focus on obtaining a deeper understanding of stem cell and immune cell behaviour in response to the scaffolds, in order to optimize their application in dento-alveolar tissue engineering.

More information on the study can be found in the paper titled published in the European Cells and Materials journal. The study is co-authored by M. EzEldeen, J. Loos, Z, Mousavi Nejad, M. Cristaldi, D. Murgia, A. Braem, and R. Jacobs.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment