A group of researchers at Linköping University in Sweden developed a set of microactuators for microrobots using a custom extrusion-based 3D printer. The actuator contains an electroactive polymer that changes shape when it is charged after printing, giving it a 4D function.

Although 4D printed soft robots are usually limited to centimeters or millimeters, specially developed technology allows researchers to reduce their driving mechanism to the micrometer range, with a thickness of about 20 micrometers. They claim that their customized machines have versatility and scalability, and hope to “expand the scope of soft robots” with the help of previously invisible complex micro-robots.

Electroactive polymer technology

Electroactive polymer (EAP) technology is the driving force behind many soft robotic devices. It describes a material that activates or activates when it is charged. In soft robots, this is equivalent to muscle contraction (which usually looks like one).

According to the researchers, attempts to reduce the size of EAP actuators often encounter many challenges. Micro-manufacturing techniques such as photolithography can achieve lower driving potentials and higher power-to-weight ratios, but often involve complicated processes. This makes it difficult to integrate them with current markets and technologies.

Here, additive manufacturing can bring many benefits because products can be modified on the fly, significantly reducing energy costs and reducing waste generation by a factor of ten. Ultimately, the team believes that this may make EAP devices cheaper and feasible for a wider range of applications.

4D printed microactuator

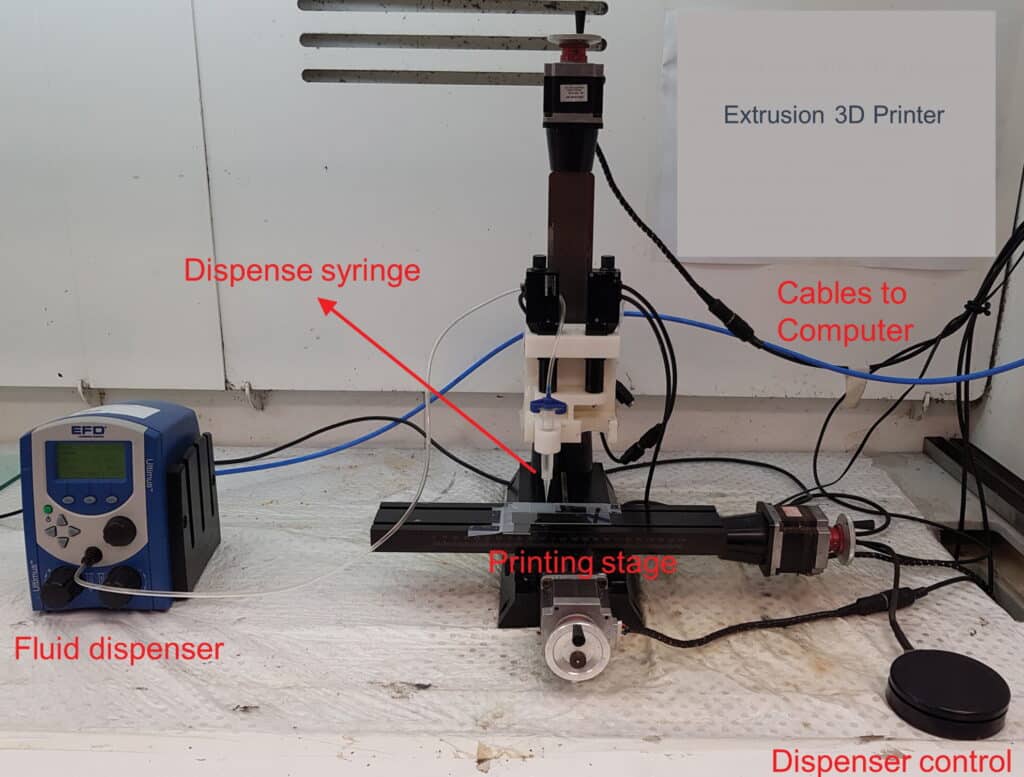

The first phase of the research involved building a printer. The basis of the machine is a three-axis programmable CNC table equipped with a high-precision fluid distribution system. Connected to the dispensing system is a 5mL locking syringe to control the extrusion rate through the lateral movement of the platform. The team used commercially available glass slides as the build plate.

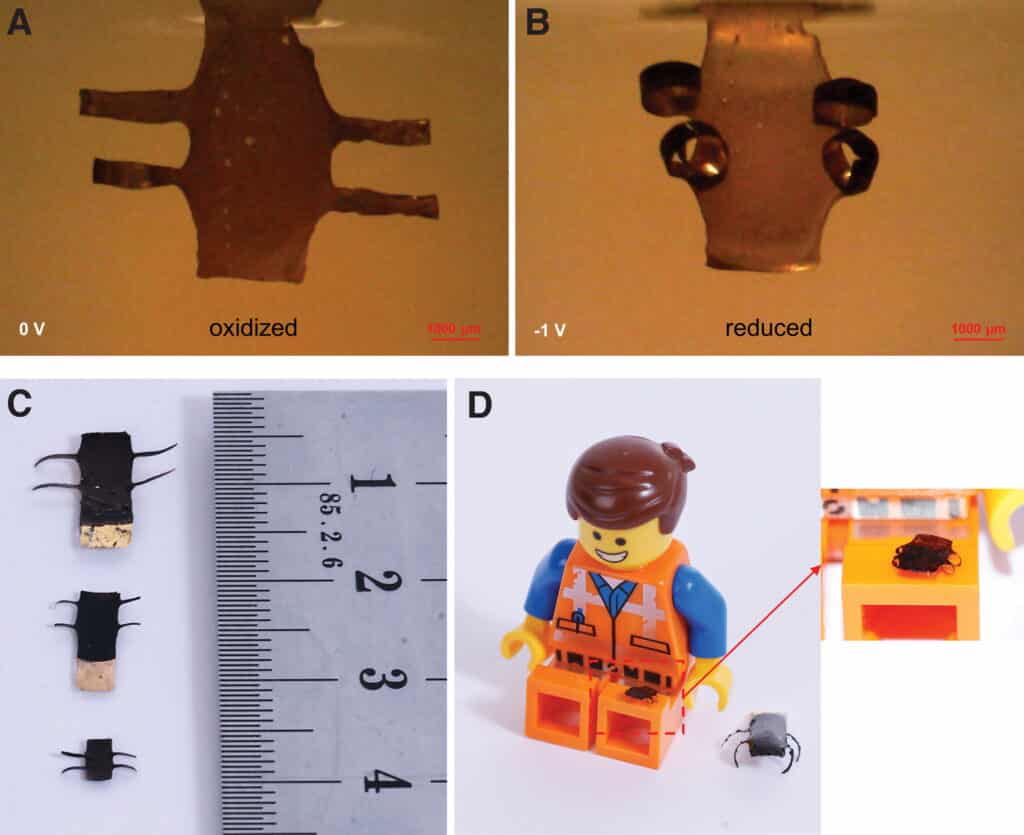

They first placed a thin layer of gold only 40nm thick on a glass slide to form a conductive layer. The researchers then used a syringe to dispense a layer of UV-curable urethane acrylate gel onto the conductive layer. The gel will continue to form the “body and arms” of the microactuator. After the gel was fully cured under ultraviolet light, the research team deposited a layer of polypyrrole (EAP) on the other side of the gold sheet.

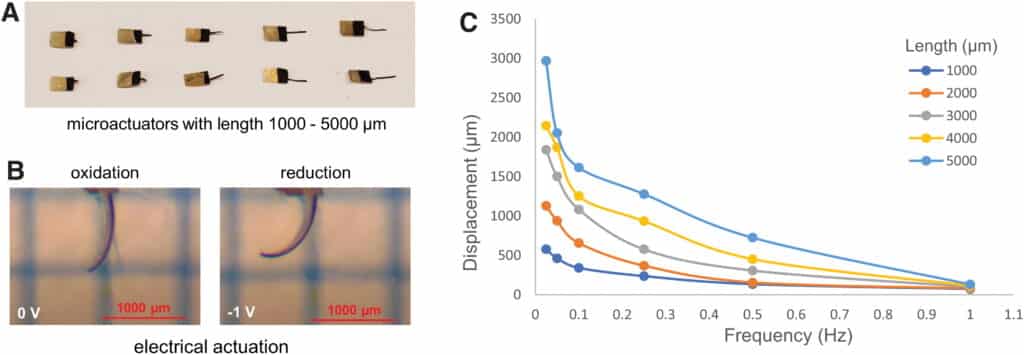

The team managed to repeat the process several times, printing out microactuators with lengths ranging from 5000 microns to 1000 microns. The thinnest microactuator they developed is only 20 microns thick. The researchers found that they can start the device with potential as low as 1V compared to the typical 1kV+ of other 3D printing methods. Scientists believe that their work shows the great potential of miniaturizing low-cost micro-robots through 3D printing technology.

More details of the research can be found in the paper entitled “3D printed microactuators for soft microrobots”. It was co-authored by Manav Tyagi, Geoffrey M. Spinks, and Edwin WH Jager.

For 4D printed soft robots, there are many different actuation methods-electrical actuation is one of them. Researchers at Rice University recently used 4D to print their own soft robots, which are activated by temperature changes. They intend to develop this technology to the extent that it can be used to reconfigure its own biomedical implants as needed.

In other places, researchers at Nanyang Technological University took this step further and printed a soft robot that does not require any real-time human input. The process involves swelling the elastomer with ethanol to induce stress in the structure of the actuator. As the ethanol evaporates on its own and the elastomer dries, the material deforms due to the elastic energy inherently stored in it.