German 3D printer manufacturer Rapid Shape has released a new DLP machine that’s specifically designed to cater to the needs of clients in the dental industry.

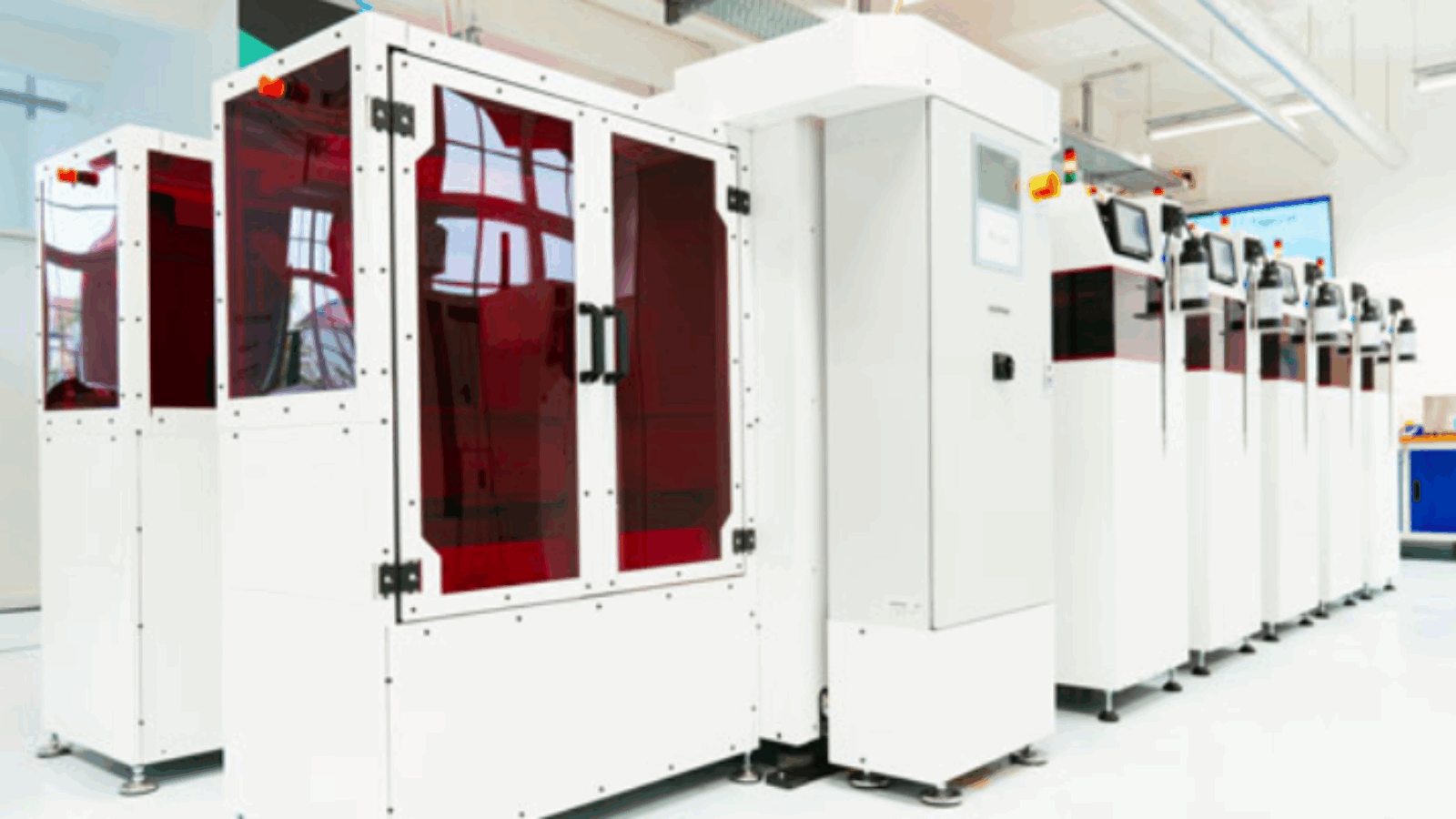

Named the RS inline, the printer is optimized for producing high-volumes of transparent aligner models cost-effectively. Rapid Shape’s system automatically ejects finished parts which enable it to fabricate over 4,000 objects per day, and by chaining the printers together, users can form an additive dental production line.

With its innovative post-processing system, the machine also automates and simplifies the post-printing workflow, while reducing material waste. According to Andreas Schultheiss, CEO of Rapid Shape, this “not only saves the expensive and less ecological disposal that is caused by isopropanol, but also resin costs can be reduced by up to 15%.”

Rapid Shape: the DLP specialist

Based in Germany, Rapid Shape develops 3D printers for its core client bases in the dental, jewelry, industrial goods, and hearing aid industries. The company’s machines are driven by its patented Force Feedback DLP printing process, which uses a measuring device to monitor the separating forces during printing.

According to Rapid Shape, this accelerates production while yielding parts of enhanced quality, and the technology remains central to the performance of its machines. In 2018, the company launched a new range of 3D printers for the hearing aid industry, which included the DLP-powered Studio-Line HA20 II, HA30 II and HA40 II.

While the HA20 II has been designed to rapidly produce parts in small quantities, the HA30 II and HA40 II are more focused on fabricating objects in higher numbers. The HA90, meanwhile, features an automatic platform changer, that provides users with high-speed manufacturing at a cost-efficient price point.

More recently, the firm has sought to expand on its technology’s applications, by partnering with Henkel to develop new materials, and validating Keystone Industries’ biocompatible resins for use with its machines. Now, with the launch of its new dental system, Rapid Shape is once again investing in, and building on its hardware portfolio.

Automating the dental printing process

Rapid Shape’s latest machine includes several features that are designed to enable dental users to drive greater productivity from their production processes. For a start, the system is capable of creating 300 models in 8 hours, and if multiple printers are connected, this number could rise to over 4,000 in just 24 hours.

The RS inline automatically pushes out any finished products within 2 minutes, making it time-efficient, and potentially an attractive option for both dental labs and factories. Additionally, if users do opt to chain a series of machines together, they can all be server controlled using the company’s proprietary RSPC application.

Manufacturing on Demand

The custom software decides which printer has spare capacity, and automatically puts it into the job queue, while providing traceability for every part to ensure that standards and efficiency remain high. “We know how time-consuming job creation and the control of production processes are,” said Karsten Müller, Sales Director at Rapid Shape.

“That‘s why the RSPC is the perfect solution to automate, track and monitor production,” he added. While Rapid Shape’s printer is powered by its customary DLP force-feedback technology, its post-processing unit features a brand new RS clean-C centrifuge, that serves to simplify and accelerate the entire process.

After printing, the system transports the models via a conveyor directly into the centrifuge, where they are spun at high speeds. This cleaning process allows users to recover up to 15% of unused resin, which ultimately reduces their net production costs, and the amount of chemical by-products generated during manufacturing.

The RS inline is also an open-material system, allowing users to source resins locally, and change them depending on the application or customer needs. Rapid Shape has installed several of the new printers for its major global clients over the course of this year, and it’s now available for purchase via the company’s website.

The growing additive market for dental

As biocompatible resins become more readily-available, an increasing number of firms have either started offering dental 3D printing services, or producing systems that allow clients to do so themselves.

Formlabs has targeted the dental market with the release of its 3B and 3BL machines, and even launched a dedicated business unit called Formlabs Dental. The desktop SLA 3D printers are designed to digitize, streamline and expedite the production of parts, so that dentists can focus on improving patient outcomes.

Elsewhere, Singapore-based dental 3D printer OEM Structo has partnered with digital dentistry firm uLab Systems to streamline the production of orthodontic aligners. The collaboration saw uLab’s uDesign planning software integrated into Structo’s DentaForm 3D printer, with the aim of optimizing its performance.

Similarly, Multi Jet Fusion (MJF) system manufacturer HP has worked with teledentistry company SmileDirectClub, to increase the production of its customized aligners. The company ran 49 HP 3D printers 24/7, seven days per week, to produce more than 50,000 unique mouth molds each day.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment