3D printer OEM Stratasys has announced that its RadioMatrix radiopaque 3D printing material is now fully commercially available in the United States. Previously deployed in limited settings, the material can now be widely used by healthcare providers, medical device manufacturers, and research institutions for advanced medical imaging, education, and training purposes.

According to the company, RadioMatrix is the first and only 3D printing material that allows precise control over radiopacity, enabling the creation of patient-specific models with consistent and tunable visibility under X-ray imaging.

“Providing full availability of RadioMatrix in the U.S. is a major step in providing cutting-edge imaging education and training,” said Erez Ben Zvi, Vice President of Healthcare at Stratasys. “By enabling radiologists and device manufacturers to produce ultra-realistic, radiographically accurate models, we can reduce reliance on traditional phantoms and cadavers while offering customizable, repeatable, and scalable solutions.”

Realistic Imaging and Research Applications

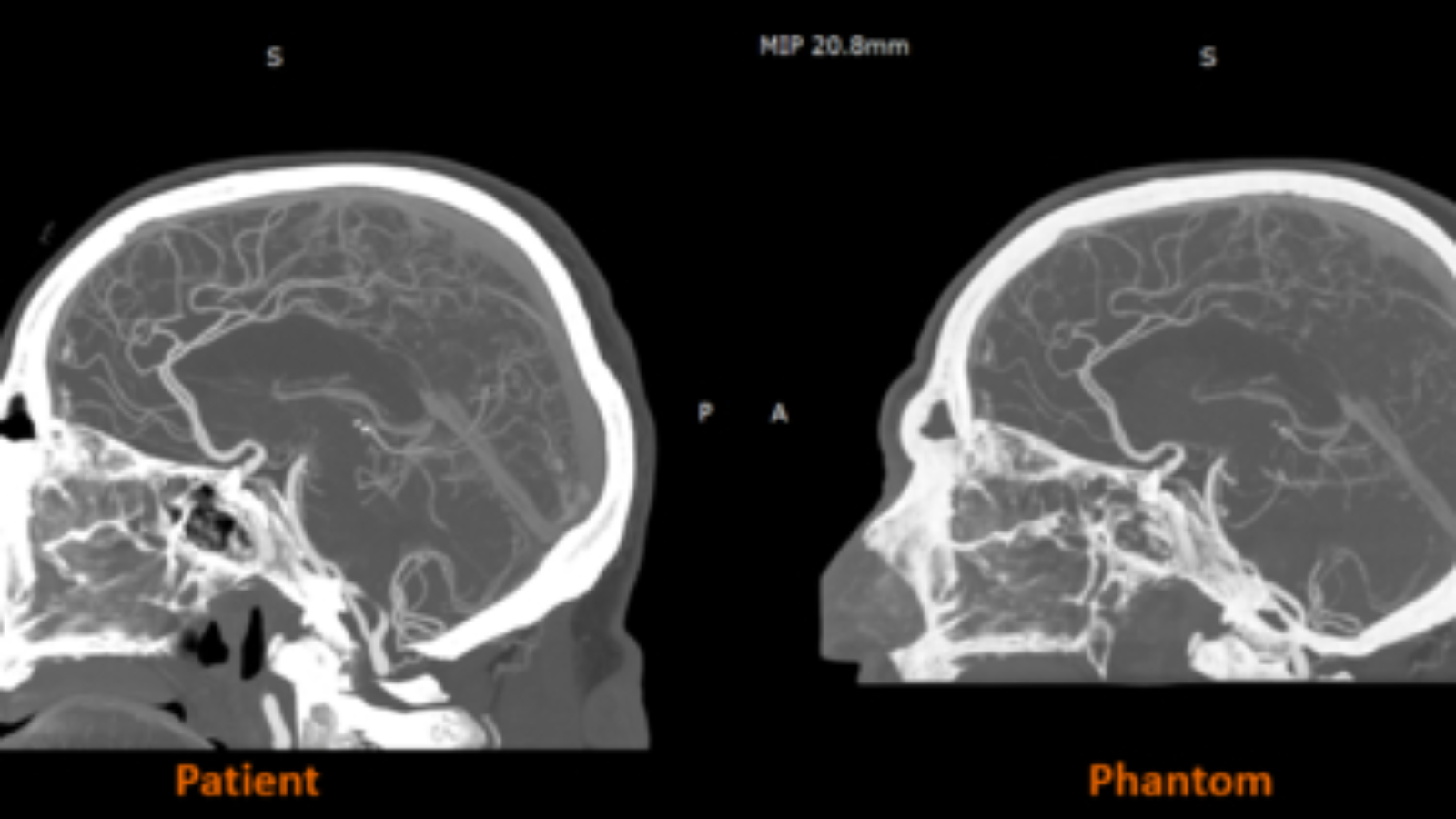

The material has already been utilized in collaborative research projects in the UK with partners including CPI and Beaumont Hospital, demonstrating its potential in clinical and educational settings. Radiopaque 3D printed phantoms, such as cerebral angiography models, are helping improve training fidelity and create repeatable environments for imaging research.

Early findings from the Stratasys–Siemens Healthineers collaboration show that RadioMatrix phantoms can replicate human tissue with high accuracy in CT imaging, with deviations as small as a single Hounsfield unit (HU) in sensitive areas like grey matter and veins. Combining Stratasys’ Digital Anatomy technology with advanced imaging algorithms, the resulting models maintain anatomical and pathological details while providing a consistent, ethical alternative to cadaver-based training.

These models are anticipated to help radiologists refine and validate CT scanning protocols while speeding up the creation of advanced imaging algorithms, enabling more accurate diagnosis and treatment planning.

Manufacturing on Demand

Stratasys’ Earlier Advances in Patient-Specific 3D Printing

Earlier, Stratasys and global provider of medical imaging technology Siemens Healthineers developed patient-specific 3D printed models that offered a more detailed, consistent, and customizable alternative to traditional anatomical phantoms. These models improved diagnostic precision, pre-surgical planning, and imaging research, showcasing the value of radiopaque 3D printing in healthcare.

In 2024, Stratasys and Ricoh USA launched a multi-center clinical study evaluating 3D printed models for orthopedic oncology. The trial, involving up to 150 patients across three sites—including The Ohio State University Wexner Medical Center and Corewell Health—will compare the effectiveness of 3D printed models versus traditional CT or MRI imaging for preoperative planning and tumor excision. The study aims to demonstrate the clinical impact of 3D modeling and accelerate its adoption in orthopedic surgery, highlighting the expanding role of 3D printing in personalized patient care.

You might also like:

Why Big Pharma Hasn’t Fully Adopted 3D Printing—Yet: Inside Triastek’s Push to Modernize Drug Manufacturing: But if the technology is so promising, why aren’t major pharmaceutical companies already using it at scale? That question guided my conversation with Triastek’s Co-founder and CSO, Professor Xiaoling Li—who argues that adoption has less to do with limitations in the technology and more to do with industry readiness.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paloma Duran

Leave A Comment