Prellis Biologics has raised $35 million and appointed a new CEO as it seeks to advance the development of its proprietary 3D bioprinted lymph node.

Raised via a Series C funding round led by Celesta Capital and Avidity Partners, and backed by Khosla Ventures, SOSV, True Ventures and Lucas Venture Group, the cash will be used to expand Prellis Biologics’ plans for its Externalized Human Immune System (EXIS), an immune system in a dish that replicates cell-to-cell responses.

Believed to be the first of its kind, the platform allows scientists to study B cell class-switching and somatic hypermutation, interactions said to be vital to antibody R&D. As such, the firm says its EXIS can be scaled into a powerful tool, not just for ramping up drug discovery, but expediting immunogenicity evaluation and tumor studies.

“Lymph Node Organoid (LNO) technology represents a significant breakthrough in access to human immunobiology,” explains Prellis Biologics Founder Dr. Melanie Matheu. “Previously, immune cells were expected to respond without the biological context of a functional lymph node. With 3D printed LNOs, we have the opportunity to accelerate drug discovery and development, while acquiring data on human immune responses all outside of the context of a clinical trial.”

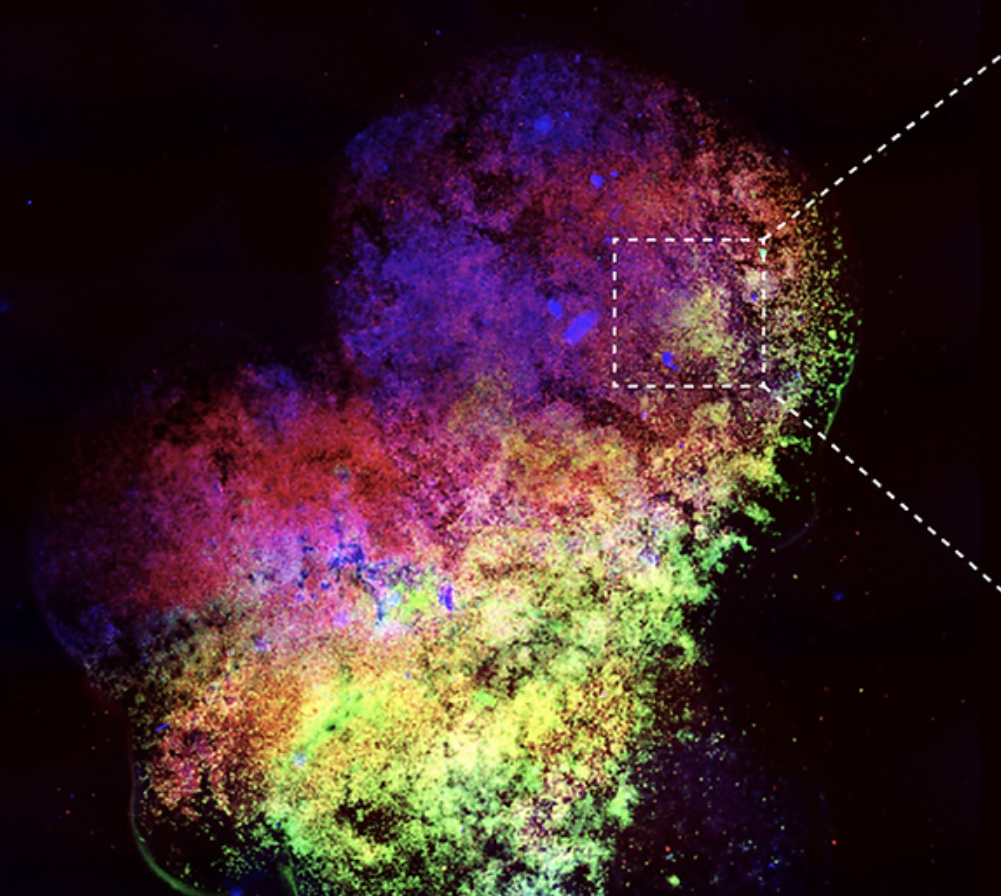

A high-resolution image of Prellis Biologics’ 3D bioprinted Externalized Immune System. Image via Prellis Biologics.

A high-resolution image of Prellis Biologics’ 3D bioprinted Externalized Immune System. Image via Prellis Biologics.

Multiphoton Holographic 3D printing

Since it was founded in San Francisco six years ago, Prellis Biologics has primarily focused on the development of its Multiphoton Holographic technology. Similarly to traditional vat polymerization, the process involves using lasers to cure materials, although in this case these are seeded with live cells and layered into high-resolution tissue scaffolds.

Using the firm’s technology, it’s said to be possible to create biomimetic vascular structures up to 400 times faster than other laser printing methods, with micron-level features. Thanks to this precision, the process also allows for the realization of tissues that can deliver oxygen and nutrients to densely-packed cell clusters, in a way that makes them valuable disease modeling and regenerative medicine aids.

Over the years, Prellis Biologics has passed numerous milestones in its efforts to improve the efficacy of its technology and test it in new applications. Having set out to 3D print kidney vessels in less than 12 hours during 2018, it later emerged that the firm had begun 3D bioprinting inside living animal models, and developed a time-saving soft tissue generative design platform for experimental scientists.

Prellis Biologics has also tried to commercialize its technology by integrating it into CELLINK’s Holograph-X 3D bioprinter. When the $1.2 million machine was unveiled in late-2018, it was said to support the growth ten times larger than standard spheroid cultures, lending it cell transplantation and therapeutic screening applications, but the firm has since gone in a different direction with the advent of its EXIS platform.

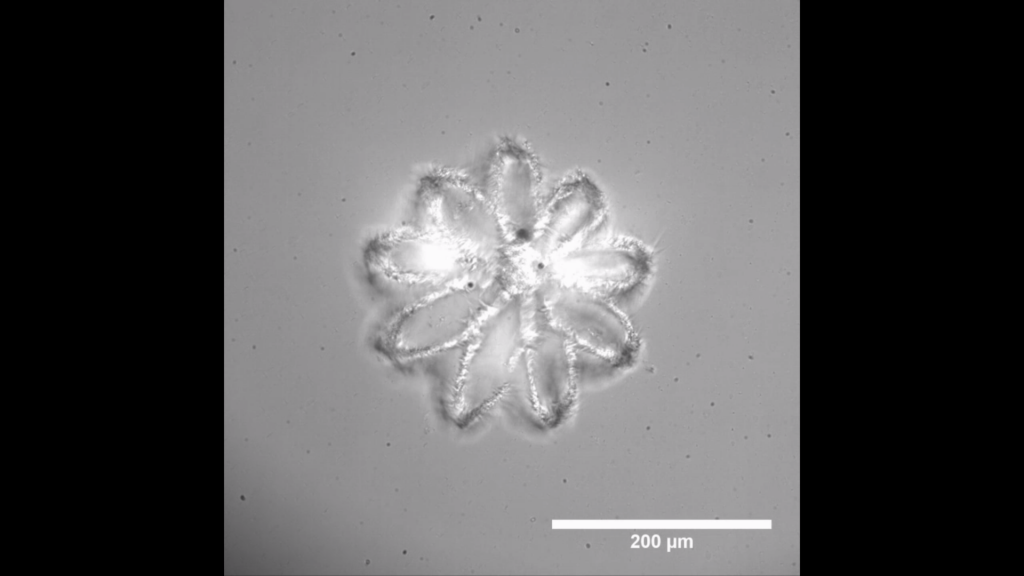

A microscopic structure for encapsulating cells made using Prellis Biologics’ Multiphoton Holographic 3D printing technology. Image via Prellis Biologics.

A microscopic structure for encapsulating cells made using Prellis Biologics’ Multiphoton Holographic 3D printing technology. Image via Prellis Biologics.

Prellis Biologics’ EXIS gets $35M backing

The EXIS platform, the latest product of Prellis Biologics’ holographic 3D printing approach, is essentially a functioning immune system in a petri dish. By challenging these lymph node organoids with a variety of target antigens, the company says it’s possible to evaluate the human immunogenicity of potential therapeutic development candidates.

Manufacturing on Demand

While the technology has clear vaccine R&D potential, Prellis Biologics also promotes it as a means of creating complex tumors, which feature microenvironments that mimic the real thing. Measuring just 2mm across, these models can be grown in 3D to closely observe their behavior in-vivo, making them ideal for transplant or longitudinal studies.

In order to further the development of its platform, the firm has now closed a $35 million funding round and carried out a senior management reshuffle. This leadership revamp has seen Generate Biomedicines’ CSO Michael Nohaile hired as CEO, with Founder Dr. Melanie Matheu stepping into the role of CTO, as well as Avidity Partners’ Lei Meng and Nobel Prize winner James Rothman joining its board.

Using the capital gained from its funding round, which takes its total raised to $64.5 million, Prellis Biologics intends to build on its 3D bioprinted lymph node, a platform that Lei Meng, a Senior Therapeutics Analyst at one of the firm’s investors, Avidity Partners, says could be transformational in the world of clinical therapeutic R&D.

“Prellis Bio’s differentiated LNOs have the potential to transform the landscape of antibody discovery and preclinical assessment of biologics,” said Meng. “We are proud to support the company’s efforts in realizing the full potential of its compelling and versatile technology platform to develop therapeutics addressing important unmet medical needs.”

Advancing therapeutic 3D bioprinting

The introduction of Prellis Biologics’ EXIS platform is one of several 3D bioprinting advances to have been announced in recent months, with the potential to help realize the technology’s personalized therapeutic promise. In February, Trestle Biotherapeutics licensed a process that combines stem cell and biofabrication technologies to enable the 3D bioprinting of functional kidney tissues.

Another company that continues to invest in the technology’s R&D, is 3D Systems. Having bought 3D bioprinting firm Volumetric Biotechnologies to supplement its Print to Perfusion program, the company is now working with United Therapeutics to develop 3D printed lung scaffolds that are being designed for human trials in less than five years.

In Finland, meanwhile, Brinter has teamed up with Tampere University to tackle what they perceive as a shortage of 3D bioprinting materials. Announced in March 2022, the partners’ first breakthrough has seen them come up with a new method of creating photocrosslinkable bioinks from gellan gum, that turns the precursor into a 3D printable feedstock with promising rheological properties.

.

You might also like:

Dentists develop unique 2-in-1 3D printed toothbrush handle for people with dexterity impairments: Using putty impressions of users’ hands, the dentists have come up with a way of modeling and 3D printing custom 2-in-1 toothbrushes and interproximal brushes from PLA. According to the team, the resulting implements are not only durable and water-resistant, but they make it easier to brush teeth, in a way that could raise the self-esteem of handicapped users by reducing their dependency on others.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment