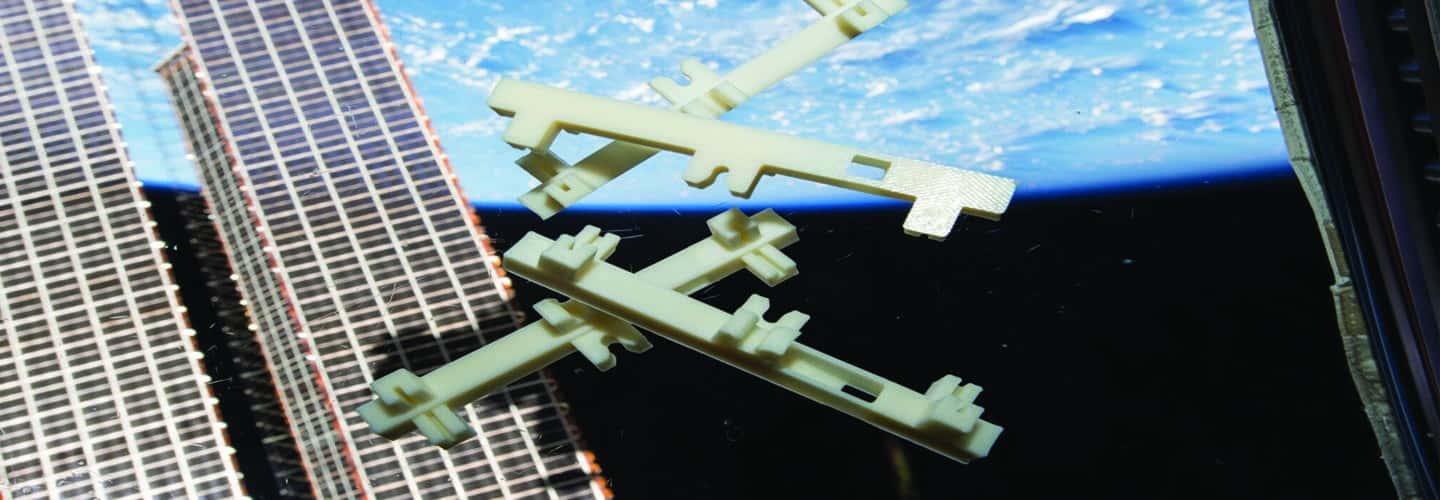

NASA’s 3D printing plan started with the manufacture of small wrenches, and it may eventually build infrastructure on the moon. However, between these two moments, astronauts on the International Space Station are testing technologies designed to improve the efficiency of the printing process.

Currently, the space station has two 3D printers, one is called Refrabrator and the other is called Additive Manufacturing Facility (AMF). The third device is Recycler, which is used to recycle used materials to save space and weight of ISS, just like Refabricator. Each method works slightly differently, and astronauts are trying to determine which method works best.

In addition to basic knowledge such as tools and small parts, NASA hopes that the 3D printer will eventually print out items that are safe for food and medical use, and that one day (once the planned Artemis 1 mission is completed) even lunar dirt can be used. As a printing material.

Koki Clinton, deputy director of NASA ’s Marshall Space Center ’s Science and Technology Office in Hansville, Alabama, said: “You want to recycle the materials you own without having to carry everything with you. You don’t want to bring 1,000 tablespoons to send Give Mars. ”

NASA’s first 3D printer arrived at the International Space Station in 2014. It added a traditional 2D printer that astronauts used to print mission-critical files and personal files (such as family photos), which was reflected in the “Feds in the Field” video in 2018.

AMF is part of the technical demonstration, the purpose is to observe the effect of printing under microgravity. Clinton said that the photograph of smiling astronaut Butch Wilmore holding the small wrench printed on the International Space Station is still the iconic image of the “Space Manufacturing” program.

But that printer needs fresh materials to make tools. Sending it to the International Space Station is very expensive. Storage takes up valuable space. NASA began researching ways to recycle plastic already on the space station, including plastic packaging, 3D printing tools that are no longer needed, and other plastic waste.

The first recycling printer shipped to ISS, Refrabricator, has been in use for about a year. It aims to recycle 3D printed plastic into parts and tools, and then send it back to the earth for analysis to understand how the recycling process affects the basic structure of the plastic.

Currently, astronauts are only testing the adhesive properties of recycled materials; Clinton said an anomaly prevented them from further demonstrating printing and recycling capabilities. The renovation plant will return to Earth in December for a comprehensive assessment.

Although the use of recycled materials for printing will be handy in the space station, it will be more valuable in the Artemis process, and the planned manned mission will be placed first on the moon in phase 1 and explored for future exploration capabilities, Mars in the first phase 2.

Clinton said that 3D printing can help future astronauts build bases on the moon, create buildings, roads, landing pads and other civil engineering works. NASA plans to use the moon’s own dirt.

He said that testing on Earth is tricky because feldspar (the scientific term for moon dust) has characteristics that cannot be completely simulated on Earth. He said: “It is not just the chemical composition, it is also the shape and size of the particle structure, including the process under extreme temperature, thermal cycle and impact, these processes all form dust on the moon,” he said.

The researchers also wanted to figure out how to extract oxygen and metals from the rearrangement stones, especially metals. NASA is also studying how to recycle these metals in printers. Clinton said: “We hope not to bring any raw materials.”