The Mission R is the latest vision from Porsche. With this study of a fully electric GT racing car, the pioneer for sustainable mobility shows what customer motorsport could look like in the future. And the 3D printed lattice seats ensure maximum comfort.

Mission R merges real racing and esports. That’s because its monocoque-like driver’s cell is designed as a module and can be used in an identical form outside the vehicle as a simulator. In this way, the racing driver can virtually prepare for his next race in a familiar environment. And tomorrow’s motorsport enthusiasts can take part in esports events.

The interaction options of the Mission R are also aimed at a young, motorsport enthusiast community: It is prepared for a live stream transmission from the interior, the driver can switch on the fans (as in online supporters) at the push of a button. These in turn can communicate with him directly, for example by sending him likes.

Realistic race training on the simulator

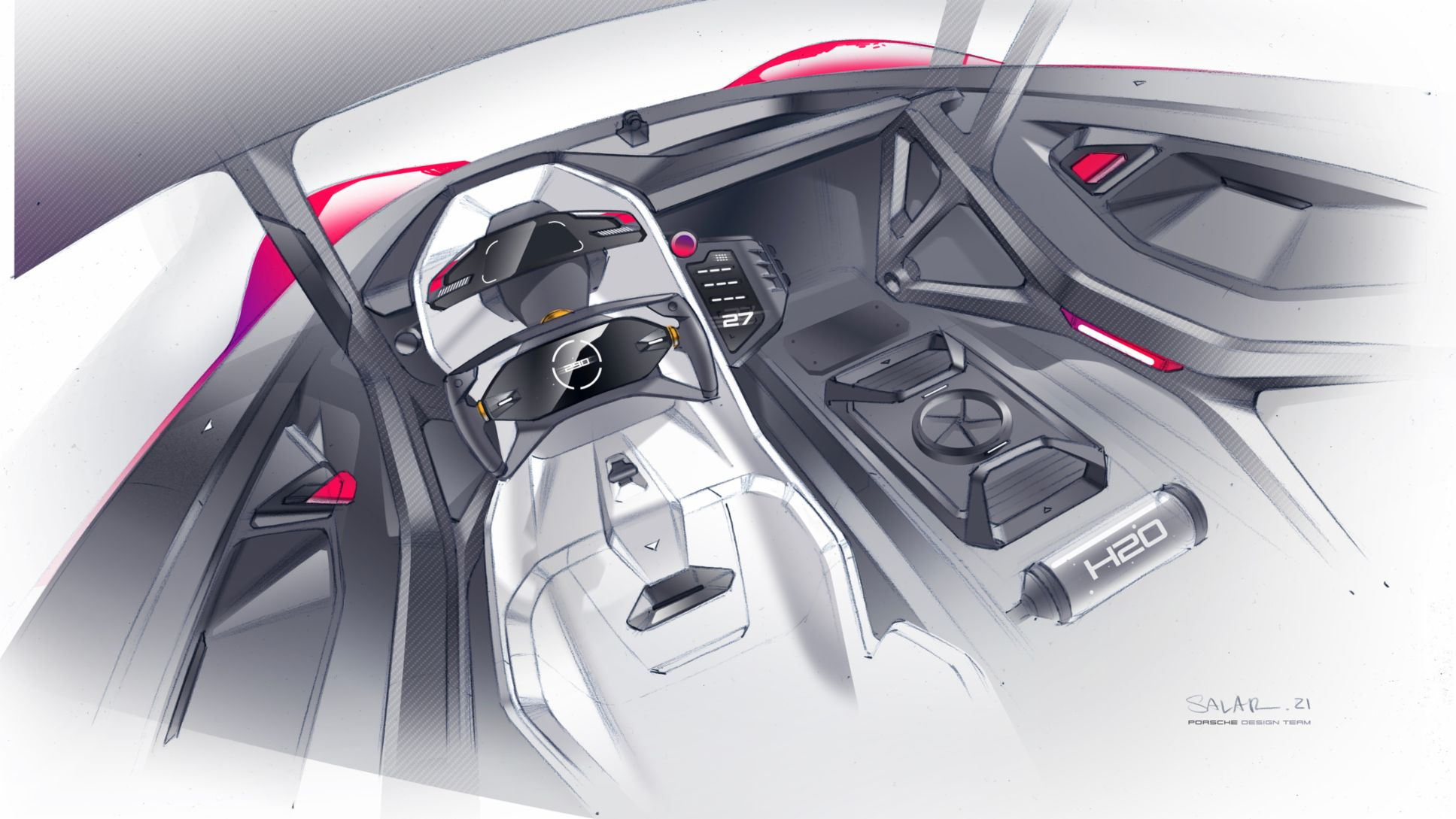

The Mission R’s seat, steering wheel, controls, adjustable pedals and screens form a compact unit and sit on one axis, the driver’s axis. In this way, the driver can concentrate on the essentials in the race. At the same time, this driver module construction enables the use of a second driver’s cell outside the Mission R as a racing simulator.

With the help of movable, electrically controlled supports, the dynamic forces that act on the driver can be simulated – for example when braking or the lateral inclination when cornering quickly. Thanks to a familiar environment with identical display and control elements and the same full bucket seat, such a training would be particularly realistic and highly efficient.

Additively manufactured, ventilated full bucket seat

The full bucket seat offers a high level of protection for the driver. At the same time, it has an innovative structure and is partially manufactured additively as a so-called 3D bodyform full shell seat. The seat shell is made of the same natural fiber-reinforced material as the exterior attachments. The middle section of the seat, i.e. the cushion and backrest mirror, comes in part from a 3D printer.

Porsche initially presented this alternative to conventional upholstery for bucket seats in 2020 as a concept study and tested it in a test phase with selected customers. As part of the new Performance Parts range, the 3D Bodyform full bucket seat is now available from Porsche Tequipment for all 911 and 718 models for which the current full bucket seat (order number Q1K) is available. From February 2022, it can also be ordered ex-works and will then be integrated into the Porsche Car Configurator.

With the concept study 3D Printed Bodyform Full Bucket Seat for the 3D printed lattice seats, the company is presenting an innovative alternative to conventional upholstery for bucket seats.

Manufacturing on Demand

In the Mission R, the driver’s seat is actively ventilated and covered with breathable fabric, which is made in a resource-saving 3D knitting process. The 3D printed lattice structure also contributes to a good seating climate. These black, coarse-meshed elements are located, among other things, at the transition between the cushion and the backrest.

Ads arranged by importance

Maximum driver orientation is the Mission R’s credo. The main displays and controls are located on one axis. This reduces distraction and contributes to better driver performance through faster reactions. The information is hierarchically clustered in three levels:

The 6-inch multifunction OLED racing display has the highest priority. It sits directly between the control horns of the steering wheel and is therefore in the driver’s immediate field of vision. Important data such as speed, lap time, tire pressures or state of charge (SoC) are displayed here. Information on ABS and traction control can also be found there.

A second screen is attached to the steering column behind it. Its curved shape is reminiscent of the large central display of the Taycan. Here, the information from the two external cameras is combined into one image. Through this digital rearview mirror, the driver can see what is happening next to and behind his racing car. A third, centrally rear-facing camera is installed under the rear window. If radar sensors and cameras detect an impending collision in the race, the Collision Avoidance System (CAS) indicates this by means of colored markings on the edges of the race display.

To the right of the driver and inclined towards him, there is a control panel with buttons and a screen is integrated. It forms the third information level. The pilot’s biometric data is visualized there. This includes, for example, his body temperature, determined by sensors in the seat.

Live stream transmission from the interior

Two cameras on the roof frame and on a running rail on top of the passenger side follow what is happening in the interior during a race in real time. The moving images can be transmitted directly to the community using a live stream button on the control panel. The fans can, in turn, communicate directly with the driver, for example by sending him likes.

Motorsport equipment such as a six-point belt, length-adjustable pedals, safety nets and an extinguishing system are of course also on board. A new feature is the combination of helmet holder and ventilation. In the Mission R, the helmet can be attached to a special holder in the position where the passenger’s headrest would be in series vehicles. During a break from racing, it is first disinfected here and then dried.

When it comes to ventilating the interior, Porsche has come up with something special: fresh air enters the car directly through an adjustable inlet in the windshield. A very efficient and therefore sustainable solution compared to conventional designs with radial fans and long routes for air ducting from the front of the vehicle into the interior.

A second seat can be installed on the passenger side for taxi rides. In the footwell there are the control units combined to form an electronic module, including the cooler. The driver’s drinking bottle is also integrated there. The expansion tanks for battery coola

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment