Combining one of the world’s most sustainable, available and strong materials with the inherently sustainable, tool-less construction 3D printing technologies could be a game-changer. However 3D printing hemp is difficult at best, as 3D printing pioneer Andry Rudenko – also a developer of both hempcrete material and construction 3D printing technologies – recently explained to 3dpbm. An Australian, Perth-based company, MIRRECO, said they are developing a CAST® hemp-based construction 3D printing process that will also be able to store CO2 removed from the atmosphere.

MIRRECO is developing hemp processing technologies to provide significant cost reductions and valuable labor/time savings for growers, as following harvest hemp can be processed into different particulate sizes for multiple uses. MIRRECO’s strategy is to establish uptake for its processing technologies in the Australian market first, before licensing them world-wide. The next stage of the strategy is the development and manufacture of products coupling hemp particulates with patented polymers for a vast array of applications using their MIRRECO CAST® (Carbon Asset Storage Technology). The combination of hemp particulates and polymers within a unique manufacturing process enables industrial CO2 to be locked away within these products. Finally, MIRRECO is carrying out R&D charter on other hemp-based innovations such as structural hemp for the construction industry and – you got it – 3D printing of homes.

One of the issues that MIRRECO wants to address is that the growth of the hemp industry worldwide is being impacted by a lack of downstream demand for hemp-based products. This issue is due in part to a distinct lack of innovation around hemp processing equipment and also to the obsolete nature of processors available on the market today.

Recognizing the gap, MIRRECO is developing a mobile, solar-powered processor that will process up to 20 Tonnes of Hemp per hour, with adjustments available to suit different farming applications (ie. other crops). Basically, this represents a quantum leap in processing capability, over other conventional decortication machines.

Manufacturing on Demand

The company identified 12 particulate variations (which can be produced by MIRRECO’s processors) for necessary grades of hemp biomass that form the basis for manufacturing a vast array of hemp products that include 3D printed structures, composites, plastics and other structural building components.

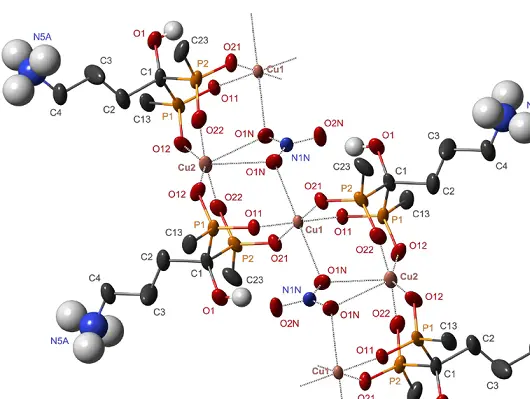

In order to do this, the company has developed a combination of non-synthetic advanced polymers and hemp to create hemp CAST products. These are based on a safe cost-effective above-ground carbon-capture, utilization and storage technology, currently undergoing testing, certification, validation and provenance. Blending hemp with proprietary polymers will complete a carbon-storing polymer chain for rapidly-deployed, high-performance construction products.

MIRRECO will manufacture its own hemp processing machinery to offer growers significant cost reductions, labor and time-savings. A team of ISO Quality Assured Engineers and MIRRECO are mid-way through commercializing mobile (and eventually solar-powered) hemp processing machines called PRO-CAST machinery which represent a quantum leap over existing conventional machines. Features include a mobile application, variable product screening, bale feed, production line integration, plant separation and a decortication module.

In collaboration with the Engineering team at Curtin University, MIRRECO are also working on the development of CO2 storing hemp-polymer composites for structural load-bearing wall panels, under various loading conditions, e.g. uni-axial and eccentric compression, flexible shear and impact loads to satisfy Australian & International standards for residential and light-commercial buildings. Evaluation of UV radiation, moisture and ambient temperature changes on durability and development of hemp composite in structural members such as beams, columns, slabs and walls for residential and light commercial buildings.

A key driving force for MIRRECO is the advancement of the baseline CAST technology from 1st generation non-structural hemp CAST, to 2nd generation structural hemp CAST and then the 3rd generation of hemp CAST 3D printing. MIRRECO are increasingly confident that for the cost equivalent of a luxury home they will be able to successfully commercialize technology to 3D print digitally designed, carbon-neutral Lumecast housing and other CAST structures, on a grand scale.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment