Meltio, a laser metal deposition technology manufacturer, welcomed the ESPRIT TNG hybrid manufacturing CAM software to its technology ecosystem, offering machine shops a single interface for preparing and programming high-quality hybrid machining and Direct Energy Deposition (DED) part production.

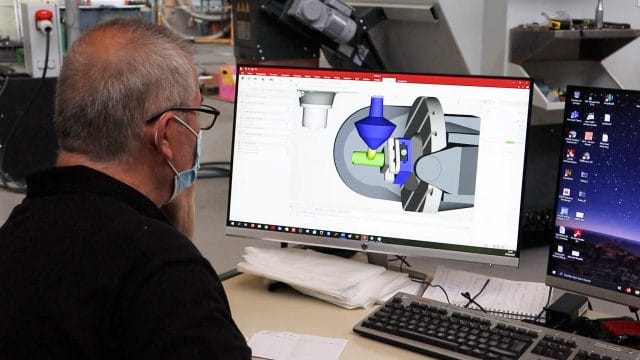

The collaboration streamlines subtractive and additive manufacturing workflows for users of the Meltio Engine CNC Integration system. Meltio’s hybrid manufacturing solution allows for the creation of highly complex parts with precision machining tolerances in a single step. Combining this pioneering technology with Hexagon’s easy-to-use ESPRIT TNG system for CNC programming, optimization, and simulation for both additive and subtractive processes results in an advanced but easy-to-use manufacturing workflow in a single tool.

“The Meltio DED Technology provides a tremendous advantage for users who want high-quality AM processes without the high capital investment in new machinery,” said Clément Girard, Product Manager responsible for Additive Manufacturing CAM at Hexagon’s Manufacturing Intelligence division. “Meltio has already provided equipment to Hexagon and our engineering teams are working together to deliver the best turnkey post-processor for supported CNC systems”.

Manufacturing on Demand

Hybrid manufacturing combines additive and subtractive manufacturing methods in a single process. This capability broadens production possibilities and enables more manufacturers to compete in the global market. It allows for near-net-shape manufacturing, prototyping, repair, and feature addition. It also enables the application of different additive materials to the same part to achieve outstanding design, weight, and strength. As a result, it allows for a rapid and cost-effective reaction to market needs with fast lead times. The solution utilizes Additive for Direct Energy Deposition capabilities within ESPRIT TNG, including side-by-side additive and subtractive programming, stock-aware cycles, and full simulation of both processes. It provides a natural workflow for hybrid machines.

To learn more about how this hybrid manufacturing solution can advance operations, Meltio and Hexagon will jointly present an hour-long webinar about the hybrid manufacturing software workflow. Sivó, a Spanish industrial machine shop will share details of their hybrid manufacturing applications powered by ESPRIT TNG and Meltio.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Andrea Gambini

Leave A Comment