The emerge of customized medical devices is closely related to the actual clinical needs. After the removal of some lesions, the wounds have a special shape and size, which cannot be matched with common medical devices according to standard specifications.

Due to the lack of customized medical devices, some special treatment needs in the clinic cannot be met. The applications of 3D printing in the field of medical device design and manufacturing have attracted widespread attention in the medical industry.

The following applications of 3D printed medical devices are particularly worthy of attention.

3D printed teeth braces

The advent of cutting-edge 3D printing technology has created more possibilities for brace customization for each patient.

At different stages of orthodontics, the braces required are different. Using 3D printing to make multiple braces will not only help the healthy development of teeth, but also reduce the cost of braces.

3D printed hearing aids

A canal hearing aid is a hearing aid that is easy and comfortable to wear and also widely used for patients.

3D printed ear canal hearing aids bring new possibilities for hearing impaired patients to hear beautiful sounds. Combining innovative materials with 3D printing technology, the shell of a canal hearing aid is “as thin as paper”, with a thickness of 0.15 – 0.2mm.

Compared with traditional hearing aids, 3D printed canal hearing aids are smaller in size, more concealed, more comfortable to wear, and less prone to fall off, enabling “invisible” wearing effect.

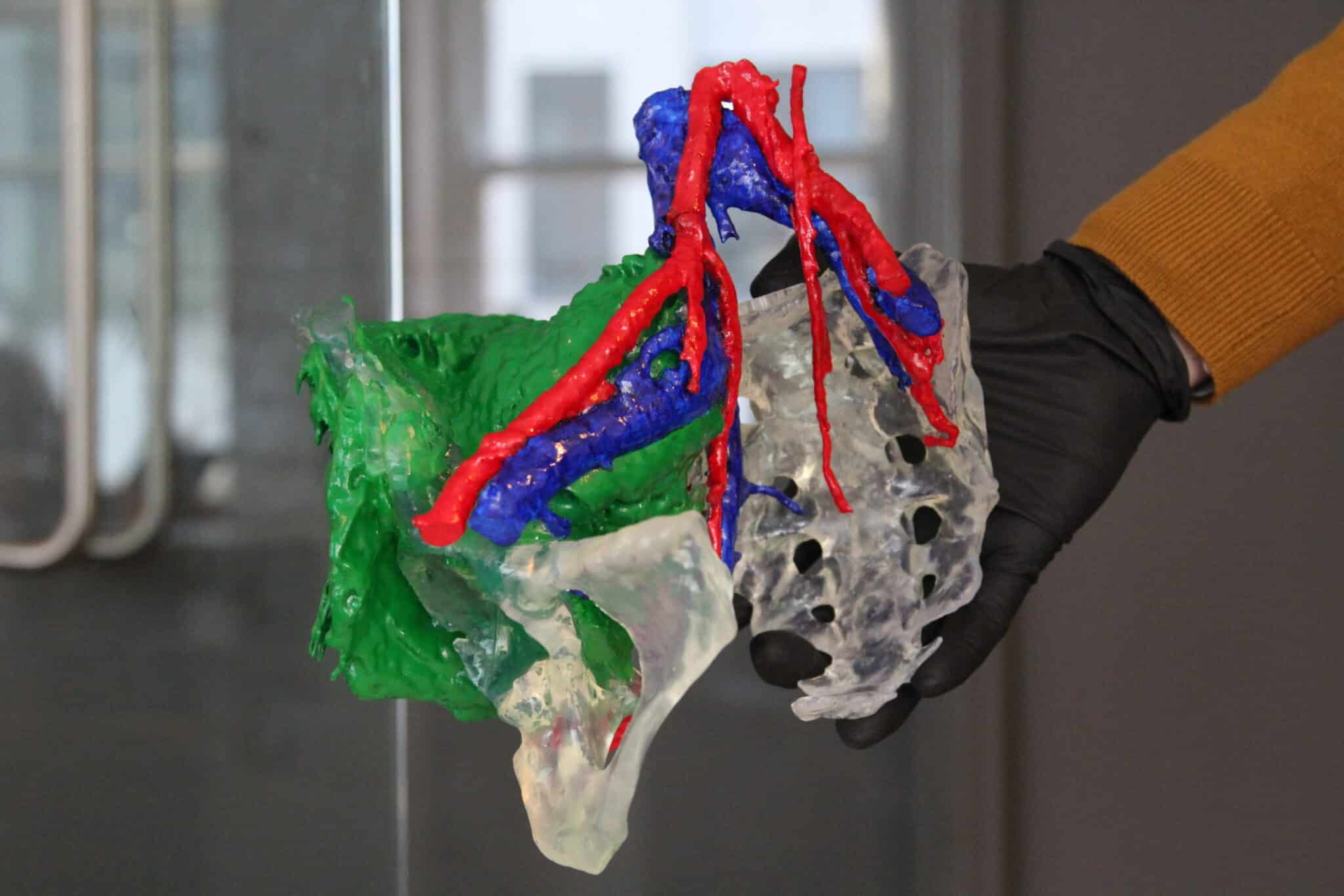

3D printed bone tumor model

Using a 3D printed bone tumor model, the surgeons and patients can more clearly and intuitively observe the local anatomical structure, the scope and boundary, the adjacent relationship with the local plexus and blood vessels, and the three-dimensional association with adjacent organs.

Secondly, on 3D printed bone models, surgical simulations can be performed repeatedly to demonstrate and confirm the best surgical plan.

3D printed surgical guide

3D printing technology can scan the fracture site before surgery, reconstruct the fractured bone in the computer, and then print out the bone model of the fracture to perform simulated surgery and choose the best surgical solution.

Through 3D printing, an individualized and accurate guide can be made. The guide can instruct the surgical instruments to perform at a predetermined point and angle to avoid damage to surrounding blood vessels and nerves.

3D printed wrist brace

3D printed wrist braces help patients who suffer from carpal tunnel syndrome, or who have weak, arthritic, injured or post-cast wrists.

Compared with ordinary wrist braces, 3D printed wrist rehabilitation braces are tailor-made, lightweight and convenient, and integrate functions like diagnosis, treatment, and rehabilitation.

Those 3D printed braces are excellent in higher customization, aesthetics, flexibility, and comfort. They are more comfortable to wear than traditional plaster ones, and have little impact on daily life. You can wear it even in bathing.

Conclusion

The fields involved in 3D printing technology have included food, medical, construction, education, and other industries. From the tool production to the protection of ancient cultural relics, 3D printing is of great value. It is making efforts in its own way for the spread of civilization and social progress. According to market research institutions, the global 3D printed medical device market will reach $ 8.9 billion by 2022. From 2015 to 2020, the market will grow at a compound annual growth rate of 25.3%, and will reach $ 7.33 billion by 2020.

Such a huge market space has also attracted many investors to enter. The introduction of high-quality 3D printed medical devices will also bring rich benefits and valuable opportunities for related companies.