Israeli electronics 3D printer manufacturer Nano Dimension has produced a micro-3D printed medical device to record the neuronal activity of mice for a new biomedical research project.

The company partnered with three leading research centers in Canada and France for the study, which will evaluate the neuronal circuits and mechanisms related to the processing of somatosensory information. In simple terms, somatosensory is the ability to sense touch, temperature, pain, and body position.

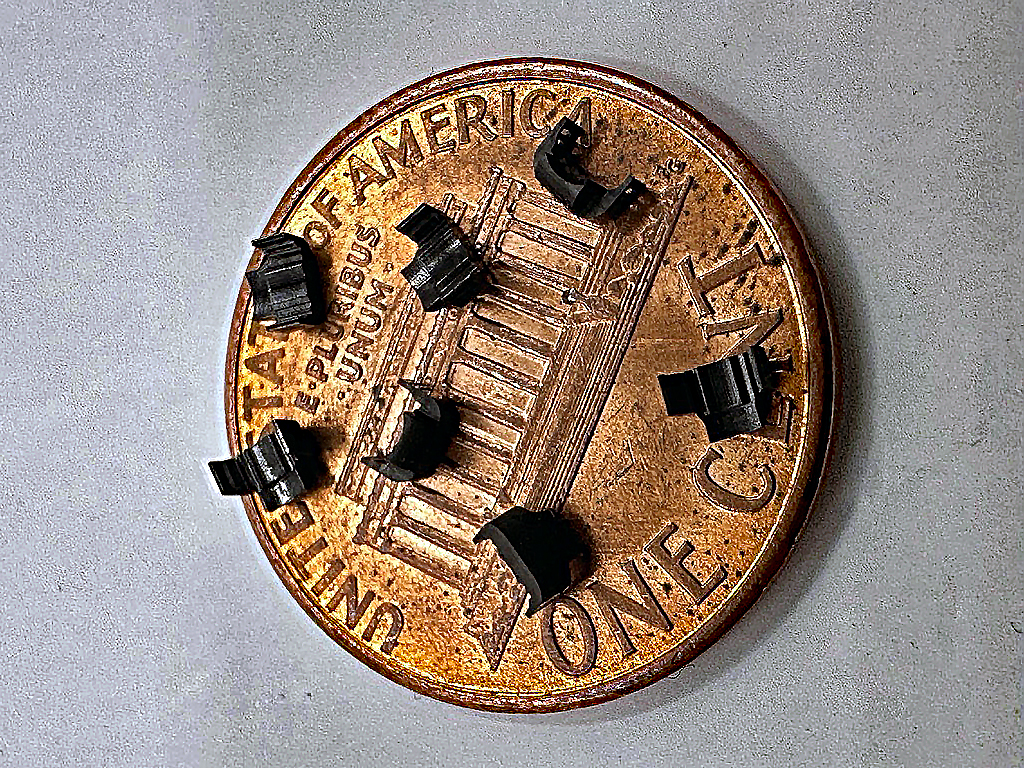

Nano Dimension leveraged its Fabrica Micro 3D printer to meet the micron-level precision requirements of the 2.7 mm-wide medical device, which includes 110μm-sized holes for electrodes.

3D printed in just one week, the device would have taken substantially longer to fabricate using conventional manufacturing processes. Louison Brochoire, a Bordeaux University PhD student working on the research project, stated that it would have taken “several months” to produce the device with alternative methods.

Brochoire added “The high precision and resolution of Nano Dimension’s micro-3D printing technology, coupled with the use of biocompatible material, empowered us to create a new tool essential for achieving our primary objective”.

He believes additive manufacturing in medical applications will “surpass many limitations.” The project’s results will reportedly highlight the key role of additive manufacturing in advancing biomedical research and developing novel medical devices.

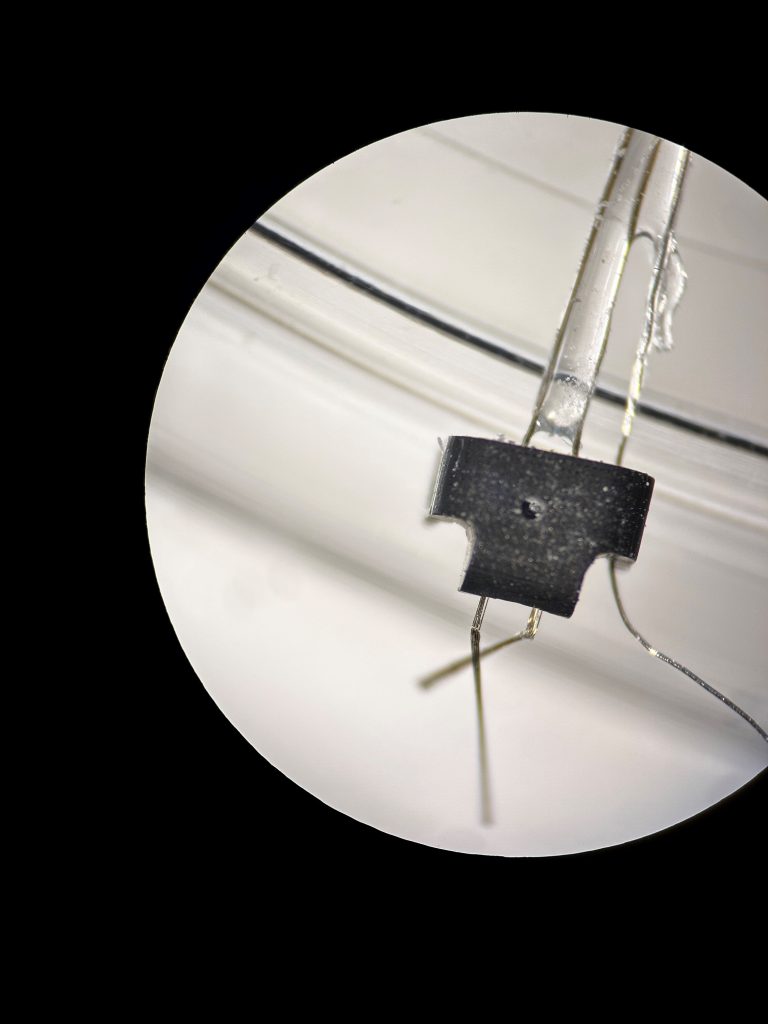

Micro-scale 3D printed parts for the medical device. Photo via Nano Dimension.

Micro-scale 3D printed parts for the medical device. Photo via Nano Dimension.

3D printed medical device enables brain scanning in mice

Micro-scale medical devices pose notable challenges in production due to their small size, dimensional requirements and intricate features. For this project, the researchers required a miniature brace that can securely hold two electrodes against a mouse’s vertebrae.

Only limited attempts have explored the electrical activity of dorsal horn neurons in awake animals. Brochoire noted that this is difficult due to the movements of mice when walking or breathing and difficulties in accessing specific points on the vertebrae.

Therefore, the team required a brace that would allow the animal to move, while “firmly securing and stabilizing electrodes that were inserted into very minute holes.” To achieve this, they turned to Nano Dimension and its Fabrica micro-3D printing technology.

This 3D printer can fabricate accurate and functional parts with tight tolerances, pixel sizes of 4μm, and layer heights between 1-10μm. Using this technology, Nano Dimension successfully 3D printed the tiny brace to the research team’s requirements.

“The ability to create such precise and minute holes within the brace was critical,” added Brochoire. “This design attribute helped to minimize artifacts caused by breathing and movements of the animal, which would interfere with our electrical signal, complicating the analysis of results.”

Manufacturing on Demand

The part was 3D printed using the company’s bio-compatible Fabrica Medical M-810 material, meeting specific requirements for implantation into a live mouse. The material is non-toxic to human cells, making it well-suited to medical device applications beyond animal testing.

The research included participation from Professor Pascal Fossat from the Institut des Maladies Neurodégénératives (IMN); Professor Yves De Koninck from Québec’s CERVO Research Center; Professor Benoit Gosselin from Québec’s University Laval; and Juliette Viellard, Post Doctoral Researcher from the University of Bordeaux.

Micro-scale 3D printing for medical applications

Micro-3D printing offers significant potential for the production of medical devices. Researchers from Massachusetts Institute of Technology (MIT) have developed a 3D printed self-heating microfluidic device for affordable disease detection.

The MIT team leveraged multi-material extrusion 3D printing to produce the device in a single manufacturing step. It incorporated biodegradable PLA and a modified material infused with copper nanoparticles that can dissipate an electrical current as heat. The size of a US quarter, the tiny device features channels 500 mm wide and 400 mm tall, facilitating fluid flow and chemical reactions.

Elsewhere, researchers from the University of Birmingham and University of Southern Queensland have used micro-3D printing technology to create microneedles. These tiny needles, smaller than a human fingertip, can be used for transdermal drug delivery across the skin barrier, withdrawal of tiny biosamples for diagnostics, and even cosmetic procedures.

The team used two-photon polymerization (2PP), a form of precise resin 3D printing adept at producing complex microstructures in the nanometer range. Fabricated on a Nanoscribe Photonic Professional GT 3D printer, the needles were produced with a laser power of 80mW, a print speed of 50,000µm/s, and slicing distances between 0.5µm and 0.7µm.

You might also like:

Ronawk partners with B9Creations to unlock the potential of 3D bioprinting with Bio-Blocks: Advanced Tissue Mimetic Technologies company Ronawk has partnered with B9Creations to develop and mass-produce 3D bioprinted hydrogels leveraging Ronawk’s Bio-Blocks.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Alex Tyrer-Jones

Leave A Comment