Austrian ceramic 3D printing company Lithoz will present the next development stage of its lithium disilicate material for dental 3D printing at LMT Lab Day Chicago 2024.

The material has been Jointly developed with integrated dental solutions manufacturer Ivoclar, and is based on the company’s IPS e.max lithium disilicate powder. According to Lithoz, this new offering will enable serial production of patient-specific, natural-looking all-ceramic dental restorations.

Lithoz will also showcase its Lithography-based Ceramic Manufacturing (LCM) 3D printing process, which is used to fabricate the dental restorations.

Visitors to LMT Lab Day Chicago can view and interact with a range of lithium disilicate 3D printed veneers and crowns at Lithoz booth F-24 between 22-24 February 2024.

“With the launch of IPS e.max press 18 years ago, Ivoclar set a material standard for dental restorations which to this day has not yet been surpassed,” commented Josef Schweiger, Head of Dental Lab, Department of Prosthetic Dentistry, University Hospital LMU Munich.

“With the LCM 3D printing technology, Lithoz has now reached a new milestone in the customized series production of lithium disilicate, which is characterized by its attention to detail, precise fit and a straightforward workflow.”

Scaling dental restoration with Lithoz 3D printing

Lithoz and Ivoclar’s lithium disilicate material reportedly allows high-quality, patient-specific dental restorations to be 3D printed in series production quantities.

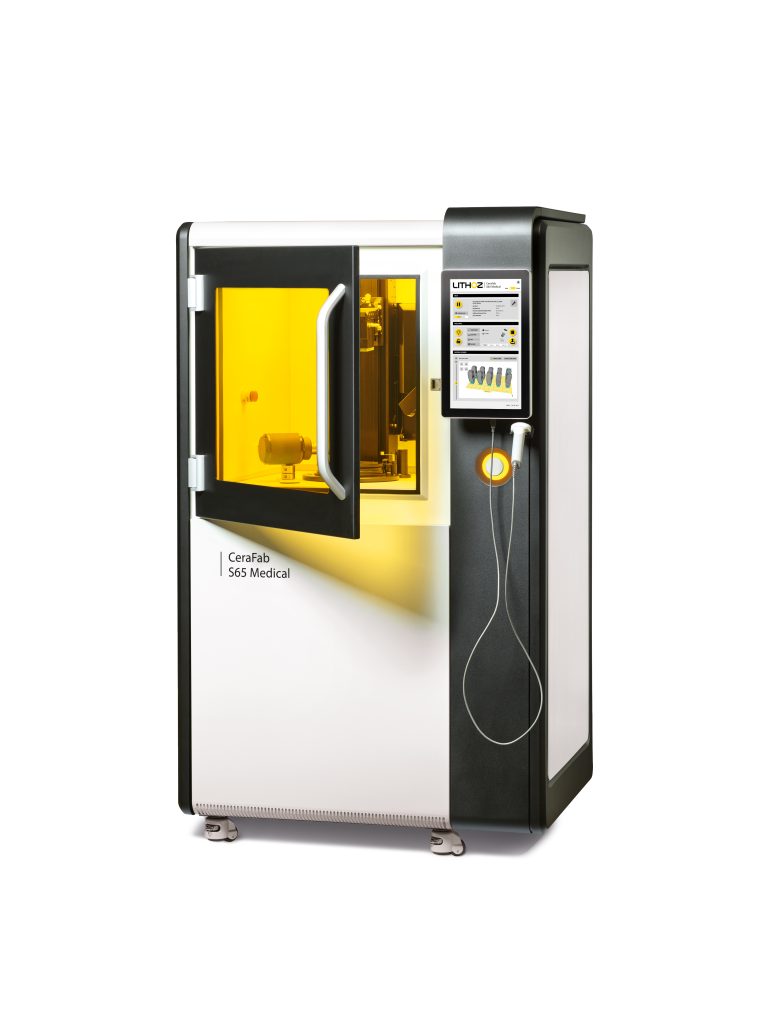

According to Lithoz, the new lithium disilicate material can be used with LCM technology to 3D print up to 50 individual restorations in a single run. Up to 350 restorations can reportedly be produced per day on a single Lithoz CeraFab System S65 Medical 3D printer.

The lithium disilicate dental parts are also said to produce zero material waste, with 8-fold efficiency compared to conventional production methods. The 3D printed restorations include veneers as thin as 0.3mm, and crowns with details that accurately represent the features and translucency of natural teeth.

Lithoz claims that the new material offering will “launch a new era of unprecedented production efficiency for large dental labs.”

Manufacturing on Demand

At LMT Lab Day Chicago, Lithoz will present LCM 3D printed dental applications, including patient-specific osteoconductive and bioresorbable mandibular augmentations made from hydroxyapatite or tricalcium phosphate. 3D printed dental implants made from zirconia (TZP-A) and alumina-toughened zirconia (ATZ) will also be displayed. Visitors will be able to pick up the parts for a ‘touch and feel’ experience.

Daniel Bomze, Director of Medical Solutions at Lithoz, will also host a free interactive workshop titled ‘3D-Printed Lithium Disilicate Restorations: The Efficient Way to Perfect Dental Aesthetics.’ This presentation, taking place on February 23 at 10:45 am, will showcase Lithoz’s new additive manufacturing process for lithium disilicate dental parts.

Developments in dental 3D printing

In a recent survey on 3D printing trends, 3D printing experts highlighted that widespread adoption of 3D printing within the dental industry is expected to continue in 2024.

The respondents also noted growing personalization in the dental market through the use of 3D printing, with practitioners moving from indirect production for mold creation to direct production of dental devices and appliances.

At Formnext 2023, Axtra3D, Oqton, and 3D Systems introduced a new dental solution targeted at meeting complex requirements of dental laboratories. The collaborative offering combines Axtra3D’s Lumia X1 printer and Hybrid PhotoSynthesis and TruLayer technologies, Oqton’s AI-powered automation, and 3D Systems’ NextDent materials.

The combined offering reportedly elevates industry standards by delivering superior surface quality, high throughput, predictive maintenance, and premium materials for on-site production in dental labs.

Elsewhere, Israel-based 3D printer manufacturer Stratasys announced that its professional-grade multi-material DentaJet 3D printer series is seeing increased adoption within the global dental industry. This announcement followed the launch of the company’s entry-level J3 DentaJet 3D printer in 2023. This dental 3D printer reportedly offers high accuracy for dental applications, whilst optimizing overall production efficiencies.

One customer to acquire Stratasys’ DentaJet 3D printing technology is Advanced Dental Technologies (ADT). This Bostin-based full-service lab purchased the J3 DentaJet system to produce its own crown and bridge, removable, and implant models.

Similarly, French dental lab Ident’M purchased J5 DentaJet 3D printer. The company now runs the 3D printer 20 hours a day to produce around 1,000 dental parts each month.

You might also like:

AddUp and Anatomic Implants collaborate on breakthrough 3D printed toe joint replacement: Utilizing titanium 3D printing technology, Anatomic Implants has developed the first metatarsophalangeal (MTP) joint replacement to replicate human anatomy closely. This partnership highlights the potential to address a significant gap in the market for 1st MTP joint reconstruction, which currently exceeds $500 million annually.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Alex Tyrer-Jones

Leave A Comment