Following its partnership with Airbus, metal AM company AddUp has collaborated with medical device startup Anatomic Implants to submit a 510(K) application for what the company claims to be the world’s first 3D printed toe joint replacement.

Utilizing titanium 3D printing technology, Anatomic Implants has developed the first metatarsophalangeal (MTP) joint replacement to replicate human anatomy closely. This partnership highlights the potential to address a significant gap in the market for 1st MTP joint reconstruction, which currently exceeds $500 million annually.

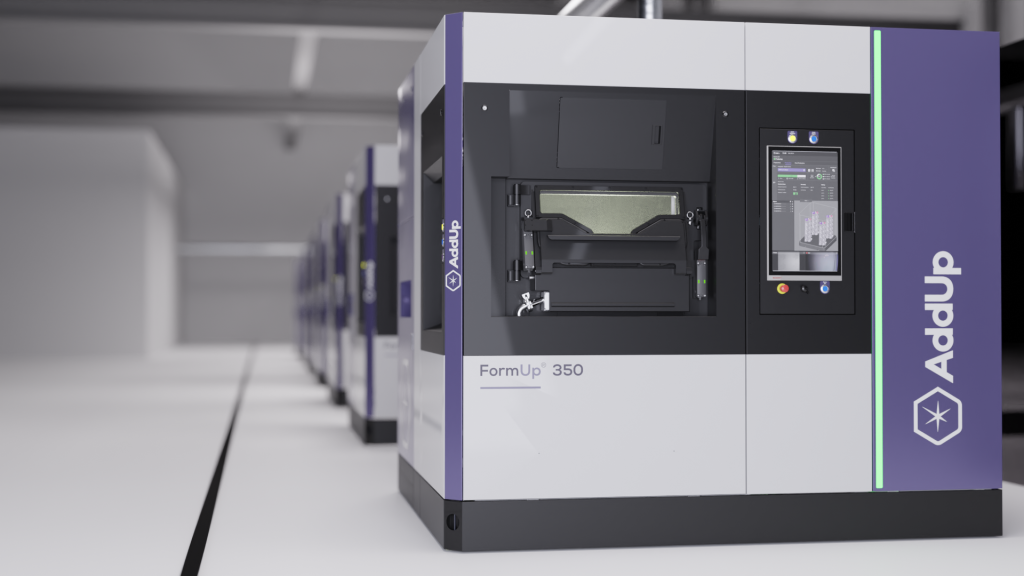

To navigate the regulatory approval process, Anatomic Implants has opted to employ AddUp‘s FormUp 350 powder bed fusion (PBF) 3D printing system. Known for its ability to produce complex lattice structures suitable for medical devices, this machine plays a crucial role in the development and validation of the 3D printed toe joint replacement.

“AddUp is committed to supporting the development of cutting-edge solutions for the medical market,” says AddUp’s Deputy CEO, Nick Estock. “Our team at the AddUp Solution Center has the expertise on FDA regulations and qualification protocols to provide a proactive approach to regulatory compliance essential for a successful 510(k) submission. We are excited to be supporting Anatomic Implants through this process to bring the first additively manufactured toe joint replacement to market.”

How 3D printing is shaping the future of orthopedic care

Conventional products in this field frequently suffer from a lack of anatomical precision and may fail to adequately encourage bone integration, resulting in less-than-ideal patient outcomes. Anatomic Implants addressed this issue by incorporating a porous structure into their design, which promotes osseointegration and has the potential to enhance patient recovery following surgery.

Since the mid-2000s, the FDA’s Center for Devices and Radiological Health (CDRH) and the Center for Drug Evaluation and Research (CDER) have approved numerous class II medical devices manufactured through 3D printing using the 510(k) pathway. According to the company, the anticipated clearance of the 510(k) application in late Q3, 2024, carries substantial potential for AddUp and Anatomic Implants, along with patients seeking innovative orthopedic solutions.

“With 1st MTP joint replacement being a largely underserved market, and medical device companies building lattice structures into implantables since the mid 2000’s, Dr. Nutter and I sought out to make a more anatomic design by leveraging the latest technologies adopted by the industry & FDA,” explains Anatomic Implants President, David Nutter. “We were excited to partner with AddUp to achieve 510(k) clearance after learning about their proprietary 3D printing technology and seeing how it could benefit the development of the Anatomic Great Toe Joint. We look forward to leveraging the AddUp team and their expertise to validate the world’s first 3D printed toe joint replacement on their FormUp 350.”

Founded in late 2016, Anatomic Implants has dedicated considerable effort to developing the Anatomic Great Toe Joint. The company has achieved a significant milestone by securing design patents in the U.S., Canada, and across Europe, regions that collectively represent the majority share of the global 1st MTP joint reconstruction market.

Customized healing: exploring the potential of 3D printed bones

Manufacturing on Demand

3D printing technology has streamlined bone reconstruction by enabling the creation of custom-designed implants tailored to individual patient needs, enhancing surgical precision, and promoting improved patient outcomes. For instance, Dimension Inx‘s CMFlex, an FDA-approved 3D printed regenerative bone graft, debuted in clinical practice, used for mandibular angle augmentation (surgery of the lower jaw) and maxillary segmental osteotomy surgeries (surgery of the upper jaw).

As a product of hydroxyapatite and a biodegradable polymer blend, CMFlex absorbs fluids, controls bleeding, and aids bone remodeling. It is the first FDA-cleared 3D printed regenerative bone graft, with wider availability planned in 2024, offering surgeons a customizable solution for bony defects in oral and maxillofacial procedures. Dr. Derek Steinbacher, Director of West River Surgery Center, and Dr. Brian Farrell, DDS, MD, from the Carolinas Center for Oral & Facial Surgery, conducted the two surgeries.

Back in 2022, Cerhum‘s MyBone, the first 3D printed bone graft approved under Medical Device Regulation 2017/745 and ISO 13485 certified, was made available to European maxillofacial and orthopedic surgeons.

Founded in 2016 as a spinout from Belgium’s Sirris Institute and partnered with the University of Liège, Cerhum aimed to replace autografts with its patient-specific synthetic alternative. Designed to treat patients with severe facial deformities, MyBone made of hydroxyapatite, features a porous structure to promote bone growth. Successful surgeries paved the way for its commercial availability.

You might also like:

Lithoz enables serial production of dental restorations with new lithium disilicate material : The material has been Jointly developed with integrated dental solutions manufacturer Ivoclar, and is based on the company’s IPS e.max lithium disilicate powder. According to Lithoz, this new offering will enable serial production of patient-specific, natural-looking all-ceramic dental restorations.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Ada Shaikhnag

Leave A Comment