Holo has appointed industry veteran John Buffington as the company’s Head of Product Engineering – a role which, now that it has been filled, will further support Holo’s momentum in scaling the growth of metal part production and commercial delivery.

“Seeing how Holo is accelerating their customer’s development cycles, saving tooling costs, and providing them a smooth path from engineering development to production for complex and high-accuracy metal AM components, was an eye-opener,” said John Buffington. “I’m excited to be joining the already outstanding talents at Holo, providing our customers with dedicated support and helping fulfil the promise of digital manufacturing of metal parts.”

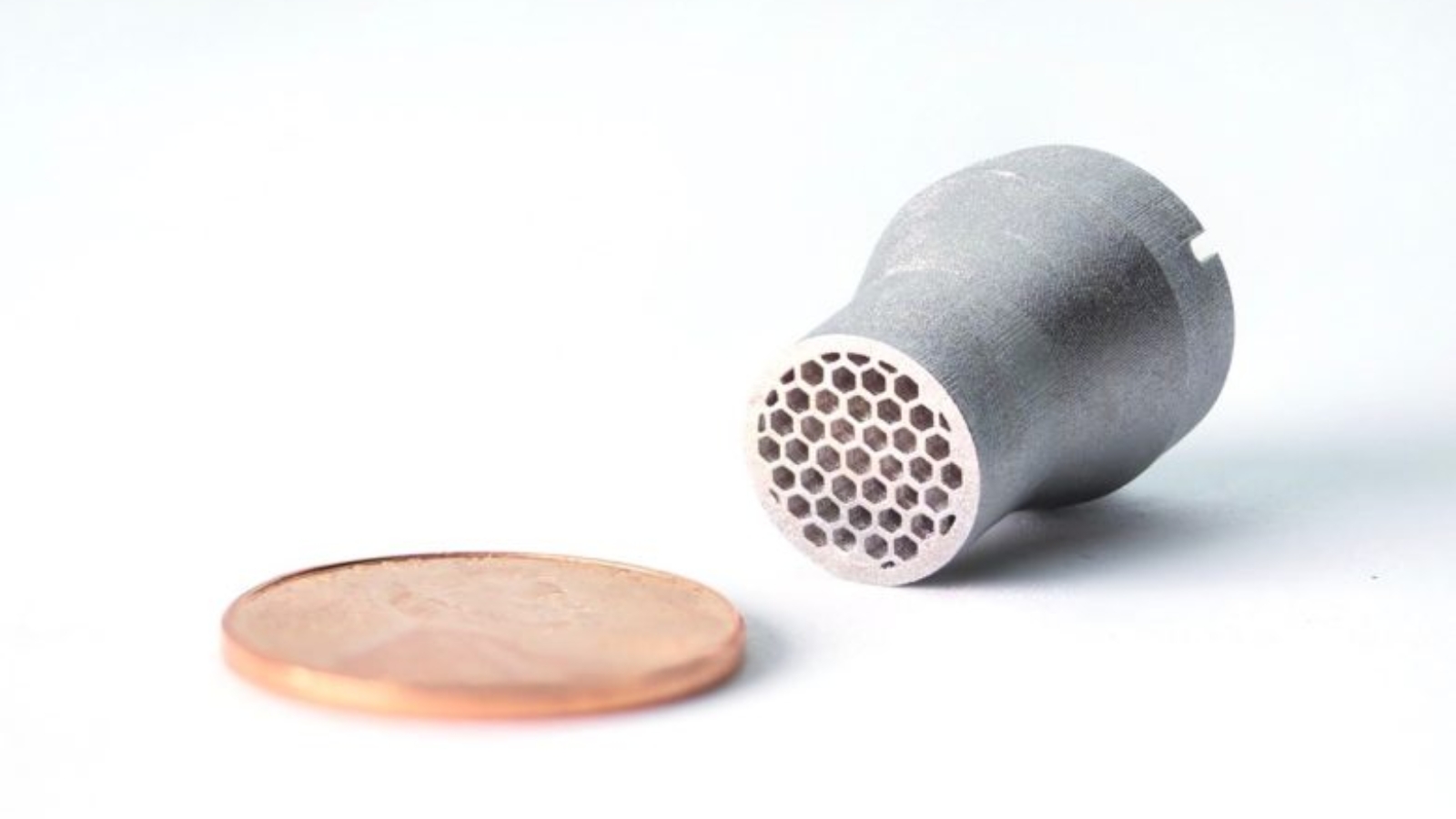

Holo, which 3D prints highly-precise metal parts in prototype and production volumes for customers’ exacting requirements, is scaling capabilities and setting new industry expectations for additive manufacturing. The company is prioritizing a strategy as a focused vertical supplier built on its PureForm technology.

With the rapid growth Holo has experienced over the last year – delivering True to CAD parts to customers – Buffington’s role in leading the Product Engineering function is a key decision for the company to continue its trajectory.

Manufacturing on Demand

“Under John’s leadership, Product Engineering will continue to expand to meet the growth in demand from our customers, including Fortune 500 companies and leaders in the medical, consumer electronics, semiconductor, and other industries, to ensure rapid delivery of highly intricate metal parts, from engineering development through to volume production,” said Arian Aghababaie, Co-Founder, President, and Chief Strategy Officer at Holo.

Buffington joins Holo from a seven-year career at manufacturing solutions provider Jabil. As Senior Manager of Engineering Services, Additive Manufacturing, Buffington worked to drive the adoption of additive manufacturing as a viable solution for progressively larger opportunities at scaled production. The global focus at Jabil enabled a truly broad focus for what scalable additive manufacturing offers to an array of end users adopting advanced technologies.

“Coming from Jabil, John has extensive experience leveraging additive manufacturing to deliver high-quality products to the world’s most demanding customers. This makes him a perfect fit for Holo. We are very excited to have him join us,” said Hal Zarem, CEO of Holo.

In addition to his tenure at Jabil, Buffington brings experience in engineering, development, and leadership from his years at battery case and accessory manufacturer, mophie, and speciality bearings producer RBC Bearings.

Holo’s PureForm technology produces parts with features less than 50 microns in size – holding tight tolerances across a wide variety of sizes. With this precision and MIM-like surface finish, Holo’s parts generally do not need post-processing.

You might also like:

SLM Solutions and IperionX sign MoU: SLM is a leading international provider of metal 3D printing solutions serving customers with an installed base of over 850 systems and 1,400 lasers, globally, having invented selective laser melting and pioneered metal additive manufacturing using metal powders via the Laser Powder Bed Fusion additive manufacturing modality.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment