During our visit to the GE Additive facility, in Cincinnati, Ohio, we were privy to the company’s most recent announcement which includes the details of its Binder Jet Line and Series 3 printer. With production deliveries expected to begin in the second half of 2023, the release of the system follows four years of customer discovery, collaboration, and testing to ensure the system is ready and relevant for modern, high-volume, serial production environments.

“In addition to a tangible business model, customers in fast-paced, high-volume manufacturing environments who are considering industrial-scale additive deployments also need to demonstrate positive financial and productivity impact, as quickly as possible. Customers shouldn’t have to reconfigure and tweak machines once they have been installed on their shop floor,” said Josh Mook, chief engineer and innovation leader at GE Additive.

“We remain focused on only bringing technology solutions to market when they are ready, and can help our customers demonstrate return on investment and total cost of ownership. That is certainly the case with our new Binder Jet Line and the Series 3, which is reliable, safe, and meets their needs today and tomorrow,” added Josh Mook.

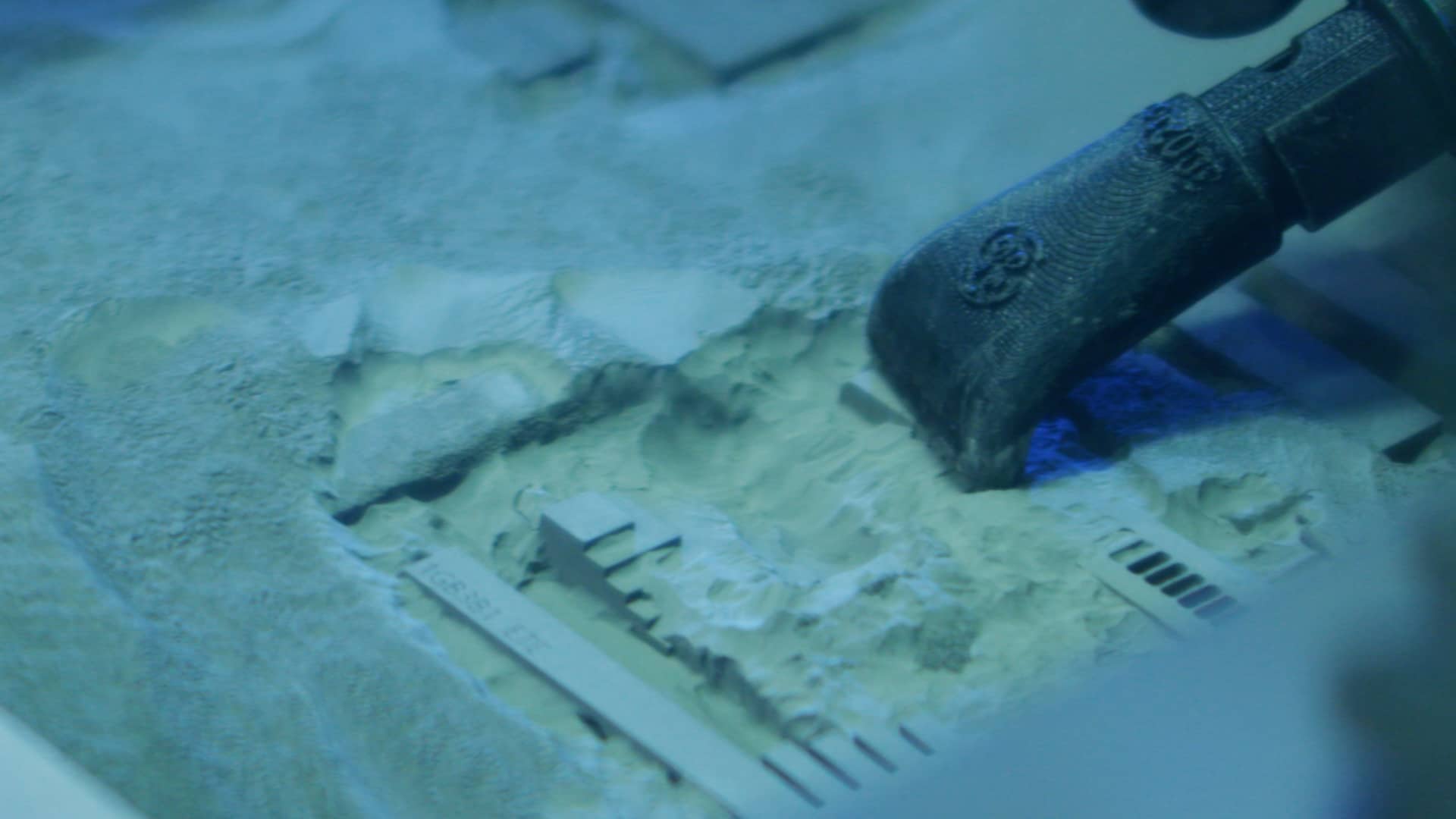

Over the past four years, a select group of strategic customer partners has contributed to the development of the GE Additive Binder Jet technology platform. The Binder Jet Line Series 3 can additively manufacture complex, small, and large parts – repeatably and reliably, with outstanding material properties that exceed casting equivalents with achievable through-hole diameters and wall thicknesses less than 500μm. GE’s Binder Jet technology has regularly proven the ability to successfully print and sinter large parts which meet dimensional and feature resolution tolerances for production, with demonstrated capability in (but not limited to) parts up to the weight of 25kg in stainless steel, and no known limitations on maximum wall thickness.

The Binder Jet Line also enables the user to de-powder intricate parts without destroying fine features, enabled by GE’s proprietary binder systems, sinter parts within the desired tolerances, enabled in part by GE Additive’s Amp TM software’s distortion prediction and compensation capability, develop casting equivalent, or better, high-quality parts much faster than traditional methods, and print and sinter parts with low surface roughness.

As GE Additive strives to make industrial metal additive manufacturing an economical process – $/cc is a critical driver of the Binder Jet Line. The further the cost of a final part can be driven down, the more application space is available for the technology.

Part of those calculations include cost comparisons to conventional manufacturing technologies, in terms of tolerances and cost, from incoming raw material to the final part in hand (total cost of ownership – not just the machine).

Manufacturing on Demand

Other cost benefits include less spent on raw materials by recycling unused powder and leveraging less expensive material (compared to other powder bed technologies), open space for new applications and innovation, utilization of the entire build box, top to bottom, edge to edge, with no need for supports, and the ability to introduce innovative parts otherwise too costly or difficult to manufacture with conventional or other existing additive technologies.

GE’s Binder Jet Line offers high overall equipment effectiveness (OEE), automation readiness, predictive distortion and compensation, and material properties that meet and exceed industry standards. The goal is for all of these aspects to come together to enable the lowest total cost of ownership for metal additive production.

Based on input from customers and partners during the technology development phase, GE Additive is focused on enabling the eventual deployment of 40, 50, and 100+ machine installations that will drive repeatable process quality, while minimizing operator contact with equipment and materials.

Other scale benefits include the ability to print up to 100X faster than other additive manufacturing modalities, automation-ready technology that drives high productivity, process and hardware designed to optimize Takt times, and seamless industrialization and integration into factory cells.

The Binder Jet Line can be installed and operated without hazard zoning required and has been designed for minimal operator contact with the system and metal powders.

The system will be UL-listed and CE-certified, has a 100% inert and sealed environment, fully closed loop powder-free exposure, and is designed for compatibility with reactive and flammable powder and binders.

Other safety benefits include zero operator powder exposure for powder load and operation, a fully independent and real-time safety system onboard, constantly monitoring of machine conditions, and real-time OPC UA data streaming for integration into factory MES and safety systems.

“Fast-tracking solutions and bringing them to market too soon is not a sound strategy and is often the reason machines end up gathering dust in R&D labs. During the Series 3 and Binder Jet Line’s development phase, we sought out customers who could give us honest, real-world insights from their high-volume manufacturing environments. We have taken their insights to complement our hands-on knowledge and experience of scaling additive production,” said Brian Birkmeyer, product line leader for Binder Jet at GE Additive. “The result is a modern, modular industrialized additive system – developed by additive users for additive users – that delivers quality parts, at cost, at scale, and safely.”

You might also like:

UltiMaker launches MakerBot SKETCH Large 3D printer: With more 3D printing power than the standard SKETCH and just as easy to use, SKETCH Large lets educators and students explore 3D printing on a larger scale, enabling students to develop their ideas further with bigger and bolder designs. With the ability to fit up to 10 student projects on one build plate, SKETCH Large allows educators to optimize print times and focus on their priorities. The SKETCH Large makes 3D printing large or multiple projects more seamless and easier than before.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment