HRL Laboratories LLC (HRL Laboratories, LLC) is one of the most innovative laboratories dedicated to ceramic 3D printing. It has developed a novel method that can be used for additive manufacturing. Components made of materials (CMC). This technology, published in the Journal of the American Ceramic Society, uses these durable materials to make a series of new complex designs possible.

Ceramic parts have corrosion resistance and wear resistance, and have excellent high temperature performance, so they are very suitable for propulsion and energy generation systems, as well as chemical processing equipment and medical implants. However, their use is limited by the difficulty of forming ceramic materials, which is a problem solved by 3D printing. HRL’s technology has the same performance as traditionally processed technical ceramics, so it can be freely shaped to manufacture high-performance CMC components.

Ceramic matrix composites (CMC) are a subgroup of composite materials and a subgroup of ceramics. They consist of ceramic fibers embedded in a ceramic matrix. Both the matrix and the fibers can be composed of any ceramic material, so carbon and carbon fibers can also be considered ceramic materials.

CMC was developed to overcome the problems associated with conventional industrial ceramics (such as alumina, silicon carbide, aluminum nitride, silicon nitride or zirconia), which are caused by cracks caused by small defects or scratches, which are under mechanical or thermomechanical load Easy to break. Fiber can increase flexibility (as with any composite material), but of course it brings new challenges to part manufacturing.

HRL researcher Mark O’Masta said: “All ceramic parts, whether traditionally machined or 3D printed, have tiny defects, such as tiny voids created during processing, handling and repair.” The problem is that when stress is applied to the area, the defect becomes an uncontrolled crack, which leads to catastrophic damage to the entire part. It basically collapses. Adding ceramic reinforcement to the ceramic matrix creates Common methods for defect-resistant parts. The challenge we solved in this project was to integrate the toughening solution with our 3D printing process. Now, we can add these reinforcement materials in large quantities to significantly enhance the 3D printed ceramics Parts. We have basically made fragile monolithic materials into durable composite materials.

Ceramic manufacturing technology must result in the lowest possible porosity, so as not to damage the final assembly. If the content of the added reinforcing element is too high, when the filling limit is exceeded, the elements will collide, and then this part will be weakened by this process. Through careful measurement and characterization, HRL reached the “sweet spot”, thus determining the most durable CMC processing range.

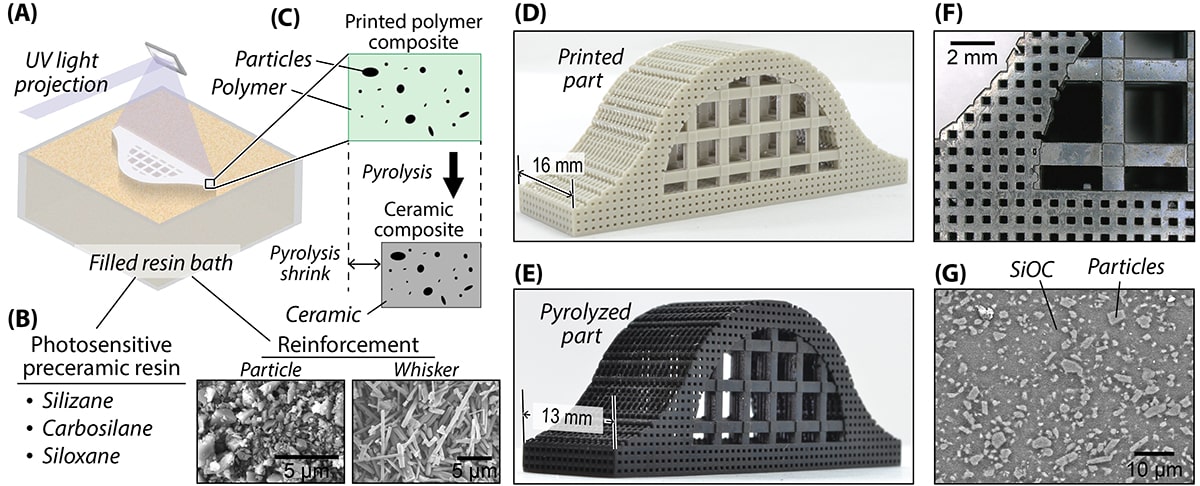

Following the publication of the 3D printing ceramic technology in Science in 2016, the HRL team adopted UV-curable ceramic materials. Digital light projection printers can cure polymers and print parts in a fast layer-by-layer method. In the current experiment, the silicone-based pre-ceramic resin is reinforced by inert particles. Then, through an extreme heating process called pyrolysis, the printed polymer parts are converted into silicon carbide carbon (SiOC), glass-like ceramics.

HRL engineer and second author Ekaterina “Katya” Stonkevitch said: “Finding an ideal way to include these enhancement elements is very challenging and confusing us.” “Through detailed research and use of light mirrors and electronics The microscope’s careful inspection of defects allows us to determine the correct processing conditions. With this information, we can print other parts for mechanical testing. This is the time for us to figure out the fracture toughness and mechanical strength. We also found that through enhancement Material, we can print thicker parts than before.”