The lighting industry is embracing the third new wave of change brought by 3D printing technologies, which are collectively termed additive manufacturing. Nowadays, many manufacturers are evaluating the technology for the cost-efficient outcome, and apply it into luminaire design and prototyping processes.

What can be realized by polymer 3D printing? What is needed to become a viable luminaire production solution? Individual companies and a consortium of interested parties are exchanging their findings on using 3D printing in tailored lighting (a.k.a., mods), custom products, also fabrication on-site and on-demand.

LED light sources and 3D printed luminaires

The senior director of strategic marketing for Lumileds, Willem Sillevis-Smitt, is convinced that LED light sources can perfectly support the 3D printed luminaires. As the LEDs are more flexible than before, the integrated drivers plus added intelligence are competent to manage stress, the luminaire can preserve better performance over life.

An LED light source “has to be able to work in a more unforgiving environment, in some ways, because the fixture might not be completely optimized and thoroughly constructed and engineered,” he said.

In recent years, LEDs are physically more flexible and color-tunable, allowing more freedom to be applied in architectural integration and luminaire design. Cars are stylish owning a special signature LED light of their brands, such as Audi.

“Contrast that with how LEDs have been adopted in, for example, office illumination: we haven’t seen many new shapes and forms. Imagine that the fixture shape and style can really be customized to what the architect has in mind for a new building. You could really start seeing new shapes and implementations of lighting. It doesn’t have to be a fixture that’s installed inside a building after the whole construction is done. It can be much more an integral part of the building architecture,” Sillevis-Smitt said.

Signify invests in 3D printing factories

Signify has seized the flexibility in styling and taken it as one of the major selling points of its customizable 3D-printed luminaires. The lightweight polymer shades and luminaire bodies can be 3D printed on demand. Besides, after customers retire the luminaires, the shells can be recycled multiple times. Thus Signify devotes a lot to promote these highly sustainable products.

“We started using 3D printing technology to create luminaires roughly two-and-a-half years ago. In Eindhoven, what we’ve seen in the professional domain is that it really creates added value for customers because we can tailor designs easier and more quickly,” said Kevin Raaijmakers, Signify’s global commercial director for 3D printing.

Sigify has grouped families of 3D-printed lighting specification lines: downlights, track lights, cylinders, and pendants. Each family can offer an array of colors, finishes, and sizes; each luminaire is printed and then assembled to order.

They’ve invested heavily in automation technology at their “hub” in Eindhoven and are opening a 3D printing facility in Burlington, MA (India and Indonesia will follow quickly). Raaijmakers mentioned Lightolier as a logical choice for the first U.S. brand that will market 3D-printed families, with perhaps new brands to be established. These products are “priced in the category where you expect Philips/Lightolier products. It’s in the sweet spot of the specification market.”

Gantri: consumers drive innovation

Raaijmakers sees an evolution towards a “pull” lighting marketplace, where demand drives innovation: fast and flexible. “I think, in the end, the impacts will be huge, because if you look back, the lighting industry is a highly ‘push’ industry, working with inventory and stock, etc. The biggest advantage even standard products are tailored and only made to order; or print to order in our case. We never, ever have stocks of finished goods.” he said.

Signify’s initial offerings for the high-end consumer are pendants and table lamps with selectable shapes, textures, and colors, plus some other details. Customers can “build” their bespoke luminaire online, WYSIWYG, and have it printed, assembled, and shipped directly within one to two weeks.

“What we’ve learned is that people want to have choices. People want to find something that really reflects their interior and interior style, but don’t necessarily need to design it entirely themselves. Few people are able to, and most don’t want to spend the time. But they do want to have the right color, the right size, and something that matches their interior,” Raaijmakers said.

Industrial Designer Alex Chow is marketing and manufacturing his Container table light via the platform: “3D printing creates a lot of opportunities to try new things you can’t do in traditional manufacturing.… It’s going to be interesting to see what happens as 3D printing evolves to be even faster, cheaper, and more available.”

Gantri CEO and Founder Ian Yang believes that removing the cost of tooling and inventory opens the field to innovation: “Unlike the traditional product development process, where designers have to fork out hundreds of thousands of dollars for R&D and pre-made inventory before they can sell, launching a design on Gantri is completely free. We believe that this stimulates creativity and risk-taking, so designers can compete on their ability to design and market – not on the size of their wallet.”

Luximprint revolutionalizes the optics prototyping method

The limitations of current polymer 3D printers mean that the material is not yet approved for outdoor use and that commercially viable, discrete luminaire shades and bodies must be relatively small; Signify quotes 60X60X60 cm.

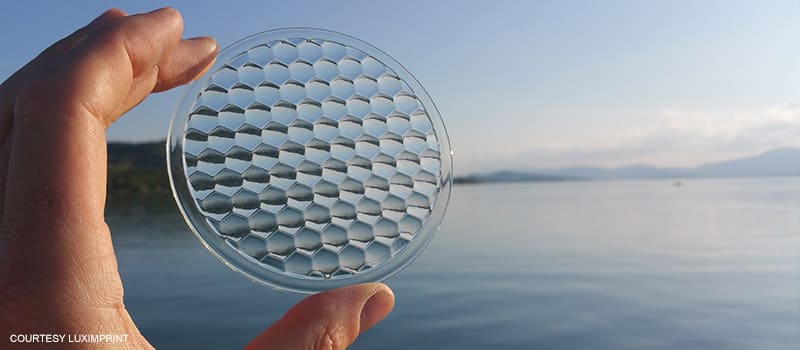

Most 3D-printed luminaires use polymer shades or bodies, but there is a continuing exploration of other parts, including heatsinks and optics. Luximprint is currently supplying optics prototypes and one-offs for manufacturers across the globe. Marco de Visser, the co-founder of Luximprint, explained that conventional 3D printing methods and materials differ from “clear material printing” with high standards for optical performance.

“There’s been a lack of validation means in the luminaire engineering cycle when it comes to one of the most critical components of the bill of materials: optics…. Now, with zero manufacturing tooling involved, inspirational and functional custom optics parts can be ordered and processed in a fast, flexible, and cost-effective way, before ordering soft or hard tools for production. Also, for pre-series and one-offs [demonstrators], the process has proven to be a commercially viable option.”

He elaborated that post-production finishing (trimming and smoothing) is not an issue in his process, and new materials are coming online for long-life, mass-market production. “The fact that 3D printing is still relatively ‘new’ is holding a real breakthrough back… the adoption of new technologies requires a certain change of mindset, which is not always easy for established and experienced engineers. People may rely on well-known and proven approaches, but miss the possibilities and advantages demonstrated by these new fabrication methods.” De Visser challenges designers and engineers to “re-think light” and consider a custom, iterative approach to design and fabrication.