Graphy, a South Korean-based manufacturer of 3D printable photopolymer resins, has developed a dental 3D printing material brand, Tera Harz, with the aim of overcoming the limitations posed by other 3D printable materials currently used within the dental sector. Graphy CEO Unseob Sim said, “Graphy’s advanced technology has to date attracted investment of $15 million.”

Founded in 2017, Graphy has won numerous awards and registered several patents for its technology, which seeks to improve the safety and mass production of new materials for the 3D printing dental market. Having previously released its customizable S Plastic 3D printer UV Resin range for dental models and surgical guides, the firm is now looking to further improve the technical performance of 3D printable dental materials with its Tera Harz brand for clear aligners.

As the technologies and materials for 3D printing dental prostheses and aligners improve, the potential applications grow increasingly wider. 3D printing has been employed by several firms operating within the dental sector as a means of increasing the accessibility and affordability of orthodontic care. According to last year’s U.S. National Health and Examination Survey, 65% of Americans could benefit from orthodontic treatment, but many never receive it due to cost and accessibility barriers.

High strength and elasticity with Tera Harz

Showcasing flexibility and heat-resistant capabilities, Graphy’s Tera Harz photocurable resin has been engineered with two carbon backbones, one of which is compounded and soft, while the other is hardened at a high temperature using Graphy’s technology. This compounding technology, which takes place at the initial raw solid material stage, enables the material’s molecular formula to be controlled, therefore allowing customization of the material specific to customers’ needs.

Included in these controllable elements is the thickness of the Tera Harz material, which can be freely manufactured to 3D print optimized and customized orthodontic appliances and dental prostheses. Deemed an eco-friendly material by Graphy, Tera Harz’s shape is restored when it comes into contact with hot water, and dental appliances printed from the bio-compatible material can be sterilized.

Graphy’s Tera Harz has acquired CE, FDA, and KFDA medical device certification, and is available in clear (TC-85DAC) or white (TC-85DAW). The clear Tera Harz material is fully transparent and possesses high durability suited to orthodontic treatment device applications. Meanwhile, the white Tera Harz material emphasizes aesthetics alongside durability. Graphy can also supply customized colors in line with the requirements of its business partners.

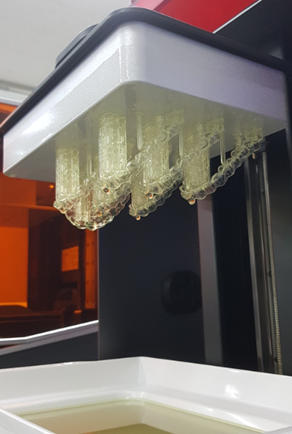

Dental prostheses printed with Tera Harz

Graphy’s material is optimized for the 3D printing of orthodontic devices such as clear aligners, flexible dentures, and crowns. According to the company, 3D printing a clear aligner from Tera Harz can take as little as one hour, while aligners manufactured via traditional techniques can take between one to two weeks to be produced. Manufacturing operations and costs are also streamlined as no film or vacuum forming processes are necessary when printing with Tera Harz.

Manufacturing on Demand

According to Graphy, its Tera Harz material could make one-day orthodontic treatment a possibility for patients, while enabling dental laboratories to produce large volumes of products with minimal factory investment. Dental experts could also see better orthodontic treatment results through being able to control the aligner’s material strength and elasticity through 3D software, and then immediately print the custom-designed aligner while the customer waits.

Tera Harz materials can also be engineered for the manufacture of 3D printable permanent crown and bridge prosthetics, namely TC-80DP. TC-80DP boasts 360Mpa in the Bi-axial Flexural Strength Test (ISO 6872) and can replace existing dental materials such as Zirconia in producing customizable permanent dental prostheses. The material is currently undergoing clinical trials, with its effectiveness having already been proved in several clinical cases worldwide, Graphy claims.

Also included in the Tera Harz range is TFD-26, which is designed to overcome the limitations of complex and laborious conventional production processes used to manufacture flexible dentures. According to Graphy, TFD-26 is the “world’s first” 3D printable biocompatible, flexible denture material, exhibiting higher elasticity, flexure strength, and elongation than conventional thermoforming resin.

The material enables the design and printing of flexible dentures based on 3D scans, which can be combined with teeth dentures made from TC-80DP using Graphy resins. These resins chemically bond the denture base and denture teeth – as opposed to mechanical bonding processes used in conventional flexible dentures – in order to prevent the artificial teeth from splitting apart from the base.

Having successfully commercialized its Tera Harz photopolymer resins for 3D printing clear aligners and permanent tooth dentures, Graphy will continue to focus on its research and development (R&D) efforts within the development of further 3D printable materials for the dental sector, in addition to attempting to overcome limitations surrounding the current processes of 3D printing dental prostheses, denture bases, denture models, and surgical guides.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment