Formlabs has launched a new 3D printer and business unit for dental 3D printing.

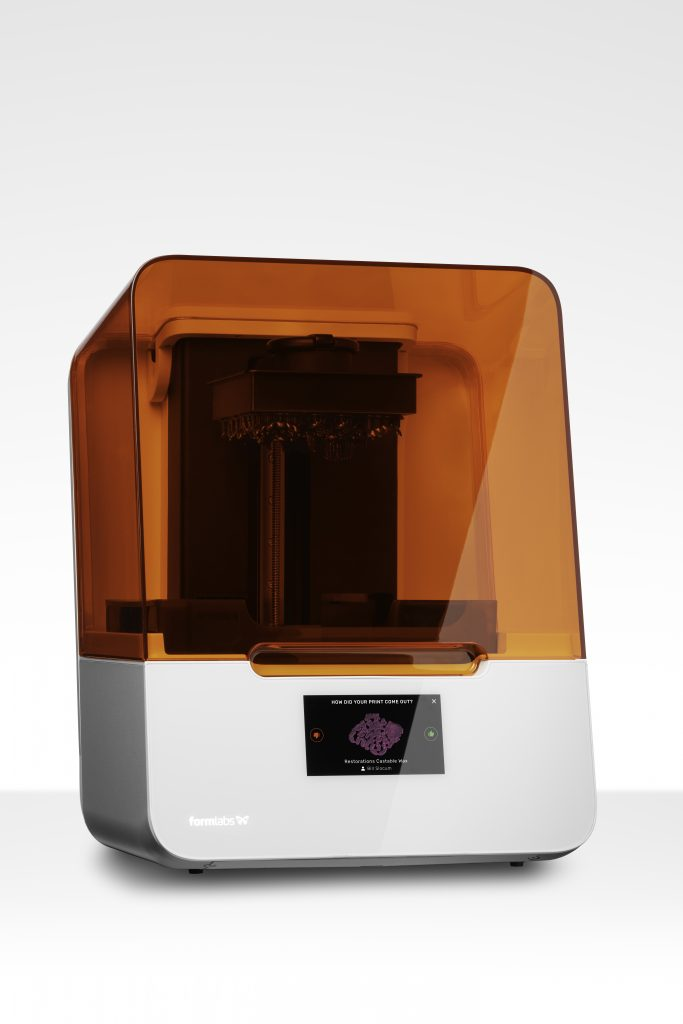

The Formlabs Form 3B 3D printer is a resin-based system marketed to dental labs and supported by an expanded range of materials. The new business unit will be called Formlabs Dental.

Max Lobovsky, CEO and co-founder of Formlabs said, “Our new Form 3B printer is uniquely tailored to seamlessly digitize, streamline and expedite workflow so dentists and technicians can focus on providing patients with the outcomes they expect and deserve.”

“We have already touched the lives of over hundreds of thousands of patients, having printed 13 million dental parts on the Form 2 and, with the launch of Form 3B, aim to expand that reach even further to ensure all dental care providers can bring an exceptional level of attention to their patients.”

New Formlabs Form 3B 3D printer

Technical specifications and pricing of the Formlabs 3B 3D printer are yet to be released but business partners with early access to the system have given favorable reports. Dr. Jay Burton, DMD, MBA, Board Certified Orthodontist at SmileMaker Orthodontics said, “The incredibly accurate Form 3B produces crisp and consistent dental parts.” Stephan Kreimer, manager at Kreimer Dentallabor GmbH & Co. KG commented, “Today’s announcement is a further validation of Formlabs continued commitment to the dental market.”

The new 3D printer uses materials formulated for the dental industry, including a biocompatible Surgical Guide Resin and four additional shades from the company’s denture materials selection. In total, Formlabs offers more than ten specialist dental resins.

Formlabs Dental will offer a Dental Service Plan run by a team of certified dental specialists. A mixture of guiding training courses and remote learning will be offered to both experienced and new users of 3D printing in dentistry. The training and support available includes personalized in-person or video training, priority email and phone support with dental specialists and hot-swapping printers for nonstop production.

The business unit will also be supported by the wider company with a team of more than 50 material scientists and print process engineers

Applications for the Formlabs 3B include crown and bridge models, clear aligner and retainer models, diagnostic models, surgical guides, occlusal splints, patterns for casting and pressing, and Dentures with 4 base and 6 tooth shades.

Formlabs is also seeking additional material partners from manufacturers and has invited resin makers to contact them.

3D printing in the dental market

3D printing and dentistry seem like a natural fit. The global dental market is forecast to reach $37 billion by 2021, and while 3D printing is unlikely to address the whole market, the ability to offer mass-customization and patient-specific solutions makes the technology appealing.

Manufacturing on Demand

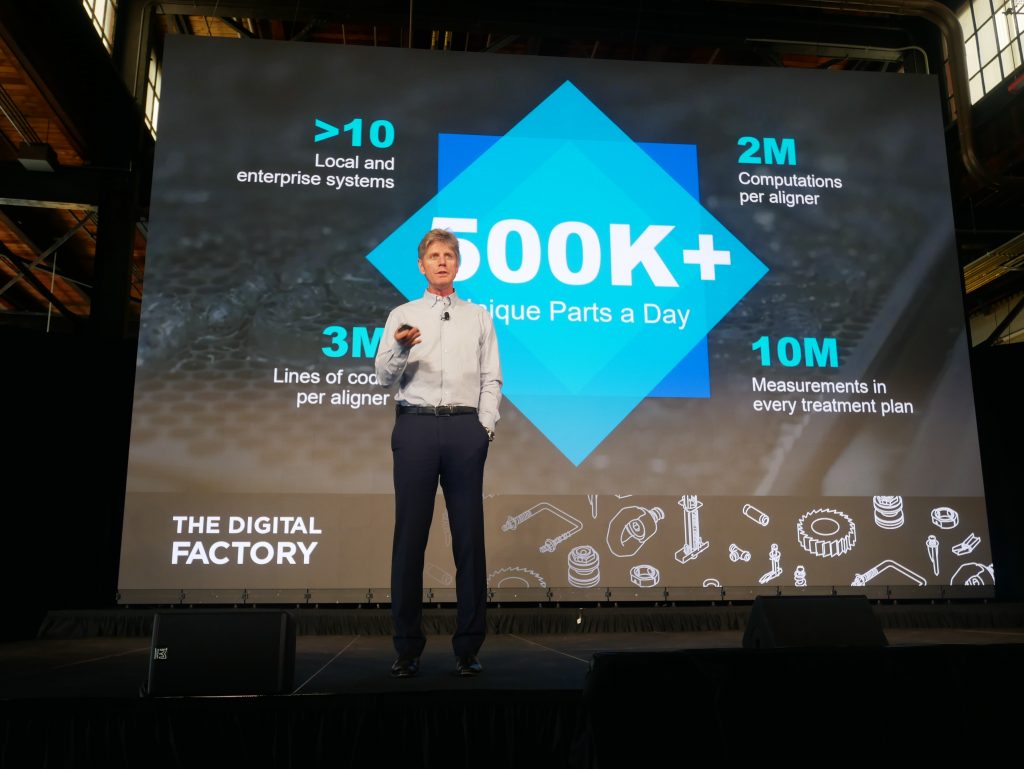

One of the stand-out success stories of the 3D printing industry is the application of 3D printing to the dental sector via 3D Systems and Align Technology. Align produces half a million unique parts every day, with 3D printing a vital part of the process.

A more recent market entrant is HP. In May 2019, SmileDirectClub announced it will use 49 HP Jet Fusion 3D printing systems to make 50,000 unique mouth molds a day, an estimated 20 million molds over the next 12 months.

The industrial additive manufacturing systems offered by the likes of 3D Systems and HP do not meet every need in the dental sector and the Formlabs Form 3B does not appear to be a solution offering such levels of throughput. A better comparison might be the range of dental focused 3D printers offered by companies such as Envisiontec or DWS.

Why is the Formlabs Dental business unit important?

The decision to open a new business unit marks another milestone in the company’s history. Little more than one year ago, in August 2018 Formlabs reached Unicorn status and advanced the process of expanding its board of directors to include heavyweight names such as former GE CEO, Jeff Immelt. The creation of a new business unit can also be taken as a further signal that the company continues to prepare for an eventual IPO, adding increasing layers of organizational structure.

Developing business units dedicated to specific market segments and deploying specialist application engineers to work with customers has been an important strategic part of long-term members of the 3D printing industry. 3D Systems has a particularly impressive healthcare division supported by the 3D Systems Healthcare Technology Center in Littleton, Colorado.

Furthermore, while the emergence of low-cost resin 3D printers has reinvigorated the market for hobbyists, established mid-range manufacturers will have a cautious eye on the market. It is not unreasonable to think that the pattern seen in the low-cost FFF/FDM 3D printer market is set to repeat itself – whereby those at the lower end have sought to move into higher price brackets to avoid a race-to-the-bottom and competing on price against companies from China, Taiwan, and the APAC region as a whole.

Building and strengthening customer relationships through the use of application engineers and vertical specialists, in this case, dental professionals, will be critical to differentiating the company.

Developing domain expertise and recruiting professionals with relevant sector experience is a longterm and costly strategy, however it is likely to reap greater dividends for companies who invest. The approach can also be contrasted with manufacturers seeking to access customers with greater spending power by adding terms such as “engineering grade” or “professional”.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Michael Petch

Leave A Comment