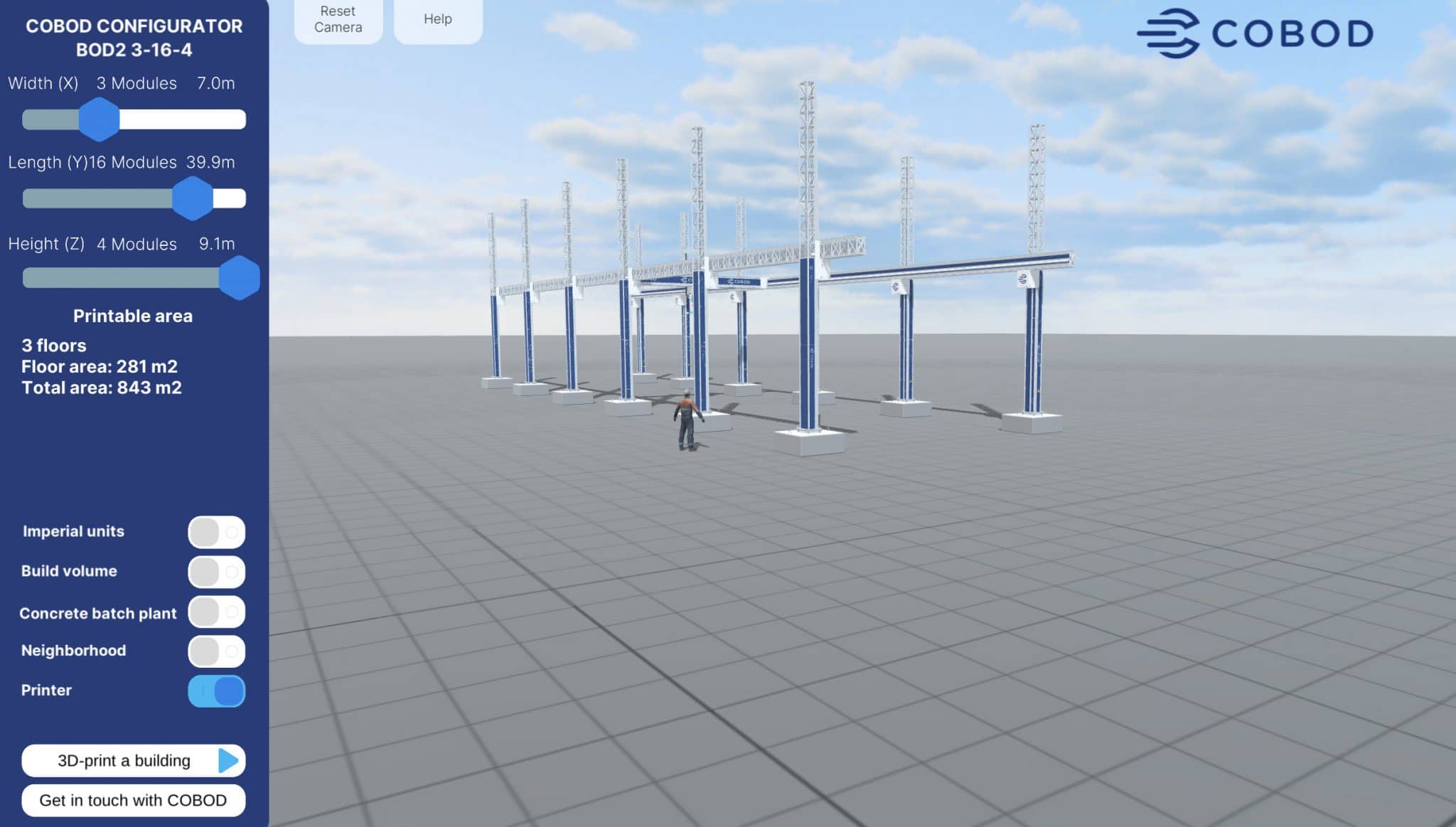

As 3dpbm had anticipated last month, COBOD has now, officially, launched the first 3D construction printer configurator – a new tool that enables contractors and developers to estimate the time it will take to 3D print a specific building and calculate the volume of concrete materials needed. For instance, the configurator shows, layer by layer, how the printer can build a 170 m2 (1.900 square feet) villa in just 26 hours.

Users of COBODs new configurator can start by configuring their 3D printer and modifying the printer width, length, and height – up to 3 story building printers. After setting up the printer, users can select a building from a library of models that reflect some of COBOD’s completed projects worldwide. Once the model is selected, users can simulate the entire 3D printing process – even within a virtual neighborhood – accelerating the print speed to see the construction progress as it happens.

Headquartered in Denmark, COBOD has become a leading provider of 3D printers to the global construction industry and is behind the printers that made the first one, two and three floors 3D printed buildings in Europe, the first school and houses in Africa, and the first 3D printed wind turbine tower pedestals made for GE Renewable Energy.

Manufacturing on Demand

According to the consulting company, McKinsey, there is a potential for doubling productivity in the construction industry by realizing the automation potential. A potential that has made the global construction industry keenly aware of how robotic 3D printers will become standard equipment at the construction sites of tomorrow.

This trend is reflected in orders for COBOD’s 3D construction printers; In 2021 revenue skyrocketed, tripling the revenue generated in 2020, already twice that of 2019.

“3D printed buildings have now become a more advantageous option than conventional building methods. This is because a 3D printer saves many resources compared to conventional methods: It goes faster, requires fewer construction workers that are so hard to find these days, and makes the working environment healthier. With our new D.fab solution for making 3D printable real concrete, locally sourced materials can be used to minimize the cost, transport, and delivery time as well.”

COBOD International’s live and 3D visualized construction printer configurator is available as an app for Android and iOS devices and as a web app edition.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Hello

I’m Samer Abdelazem, Procurement Team lead at Cemex Egypt,

I watched your amazing model of 3D printer yesterday,

I would lime to show it as a new project to The Top Managenet at cemex Ready mix Egypt, waiting your reply

B.R

Hi Samer, thanks for reaching us, please send your project to info@facfox.com so we can evaluate 🙂