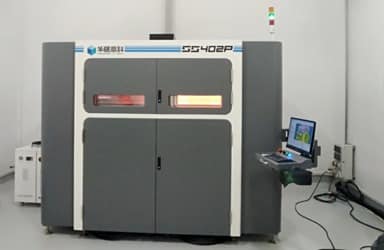

Hongtao Wu from FAW-Volkswagen was an early OEM user of 3D printing technology in China. In 2004, FAW-Volkswagen established a trial production department to learn from the experience of German Volkswagen and purchased the first Stratasys FDM printing equipment in 2005. At present, FAW-Volkswagen has a total of three printers in operation, namely 3D Systems iPro 8000, Fortus 450, and SS402P. As TCT coming soon this year, we talked with Mr. Wu about FAW-Volkswagen about the road to 3D printing.

Is 3D printing a mature technology in OEM?

What are the mainly involved 3D printed parts?

In fact, the real advantage of 3D printing technology is still in low-volume production. It is already quite mature means in R&D. Over the past 10 years, SLA, SLS, and FDM 3D printing all have advantages in trial production, both in terms of price and cost performance.

At present, our 3D printed parts are used in trial production, mainly used as mounted parts. That is, we do not test the performance of the 3D printed parts themselves, but only use them to carry out other parts for experiments or vehicle performance tests. A small plastic part has little effect on the performance of the vehicle test.

Recently, 3D printed parts are used in vehicle manufacturing and production, mainly based on tooling and fixtures. In this regard, the application has been popularized in the past two years.

FDM printing technique is more suitable for tooling and fixtures, and it has advantages that the use and operation of the equipment are relatively simple. Also, the honeycomb structure can be realized internally and eliminate the residual internal stress of the parts, ensure a relatively stable size and shape, thus the parts will not deform as time flies.

In addition, the FDM printing technique generally adopts ABS material. This material has a great advantage that it has moderate flexibility, so it’s more suitable for making tooling and fixtures that directly contact the surface of the parts.

A too-soft 3D printed parts will be easily damaged and worn, while a too-hard one will scratch and destroy the surface of other parts. We will consider using the SLS printing technique when making fixtures that require high strength and scratch resistance. Generally speaking, at present, trial-manufactured parts tend to adopt powder sintering technology.

The largest advantages of 3D printing

The biggest advantage of 3D printing is still in low-volume production. For high-volume production like hundreds of thousands or even millions of pieces per year, the molding technology is more suitable, both in terms of cost and efficiency. Even if 3D printing will be used in batch production in the future, it will be mainly based on low-volume manufacturing, such as the development of hundreds of vehicles.

At present, 3D printing is mainly used in high-end cars, and many of their components (including metal or plastic parts) can be manufactured by 3D printing as their output is very small. It is not cost-effective to make molds for these cars. However, for general automotive, the output of which is at least several hundred thousands, the molding process will be more economical.

But on the other hand, the essential advantage that 3D printing can print parts with any complex structure, which determines that the 3D printing process is destined to occupy a place in the future mass manufacturing field. For parts that cannot be manufactured by traditional processes, 3D printing technology will show its talents! In fact, for metal parts with small and complex structures, 3D printing has cost and efficiency advantages over CNC machining.

The bottleneck of using 3D printing in automobile applications

In fact, there is still something unsatisfactory in 3D printing. Simply speaking, if you want to obtain a 3D printed part with high strength, excellent surface quality, and good temperature resistance, for now, it’s impossible. This is a big problem and its solution depends on the progress of 3D printing technology as well as the development of material science! For the automotive industry, we mainly concern these three parts: high strength, excellent surface quality, and high-temperature resistance,

The SLS process itself has good strength and temperature-resistance, but the surface is slightly worse. SLS parts are generally printed with nylon or modified nylon material. This material is relatively rigid, which is difficult to handle and to polish. In addition, the current labor cost of post-processing is relatively high, so we usually do not process the surface of SLS printed parts but take them as structural parts. Tooling and fixtures that directly contact parts are generally not printed with SLS because Nylon parts can easily scratch the surface of the other parts.

For the plastic parts used in automobiles, the strength that nylon can currently provide is sufficient. When it comes to temperature resistance, the melting temperature of nylon material is 140 ℃, adequate enough for daily use. However, the surface quality of the Nylon material is slightly worse.

For display parts which need a high-gloss or mirror-like smooth surface, we usually use SLA technology. It usually adopts resin material, which would own a nice surface effect after simple post-processing. However, SLA parts placed in the open air for a period of time are easy to absorb moisture and get deformed. Therefore we usually take the SLA printed parts as the patterns for molding, or as short-term display models.

FAW-Volkswagen will closely follow the 3D development trends. I personally prefer SLS technology. This technology will have a great and far-reaching impact on 3D printing, and many of the printers with the best development momentum currently use SLS technology. We believe 3D printing will evolve as the development of material science.