Solid metal 3D printing expert Fabrisonic successfully used its patented Ultrasonic Additive Manufacturing (UAM) process to fuse different amorphous alloys into the multi-metal coating.

As part of the NASA SBIR research, the company deployed ultrasonic energy instead of traditional laser-based 3D printing methods to combine different corrosion-resistant alloys. Using its proprietary manufacturing technology, Fabrisonic is able to connect metal to the crystal substrate without destroying any of its beneficial properties.

The resulting metal mixture has higher strength and corrosion resistance than ordinary crystalline alloys, which may make it very suitable for future cladding applications in the aerospace industry.

Fabrisonic’s ultrasonic additive manufacturing technology

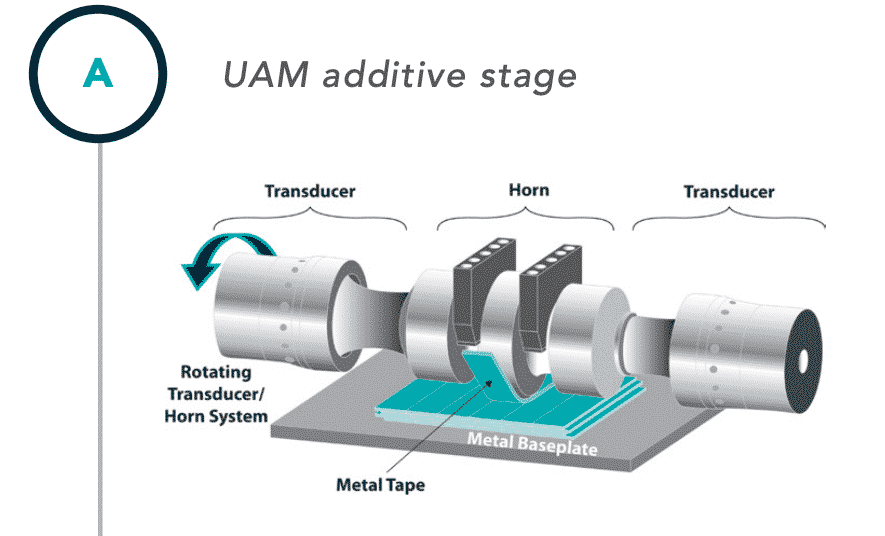

Fabrisonic’s UAM technology is a hybrid metal 3D printing process that can ultrasonically weld a series of metal strips into a 3D shape. The method operates at low temperatures, which allows dissimilar materials (such as electronic products) to be embedded in metal alloy structures.

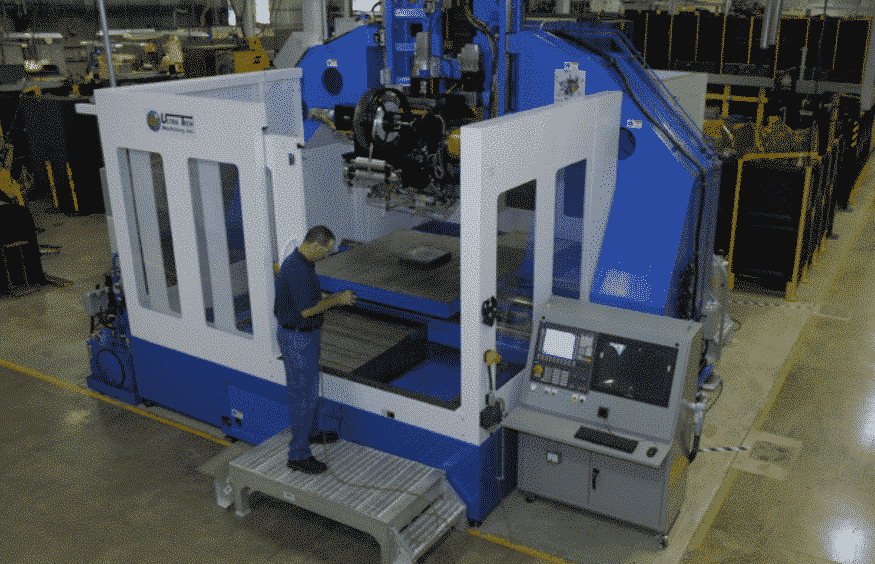

With the accumulation of metal objects, CNC machines can also be used to complete their inner and outer surfaces. Compared with the traditional metal 3D printing process, it allows users to create more detailed shapes. Since the company applied for a patent for its UAM printing technology in 2017, it has been releasing its SonicLayer 1200 machine, which also has its UAM technology.

In order to find new applications of patented 3D printing technology, Fabrisonic has established partnerships with many US government research institutions in recent years. The company worked with Oak Ridge National Laboratory (ORNL) to deploy UAM on the 3D printed control board of ORNL’s High Throughput Isotope Reactor (HFIR).

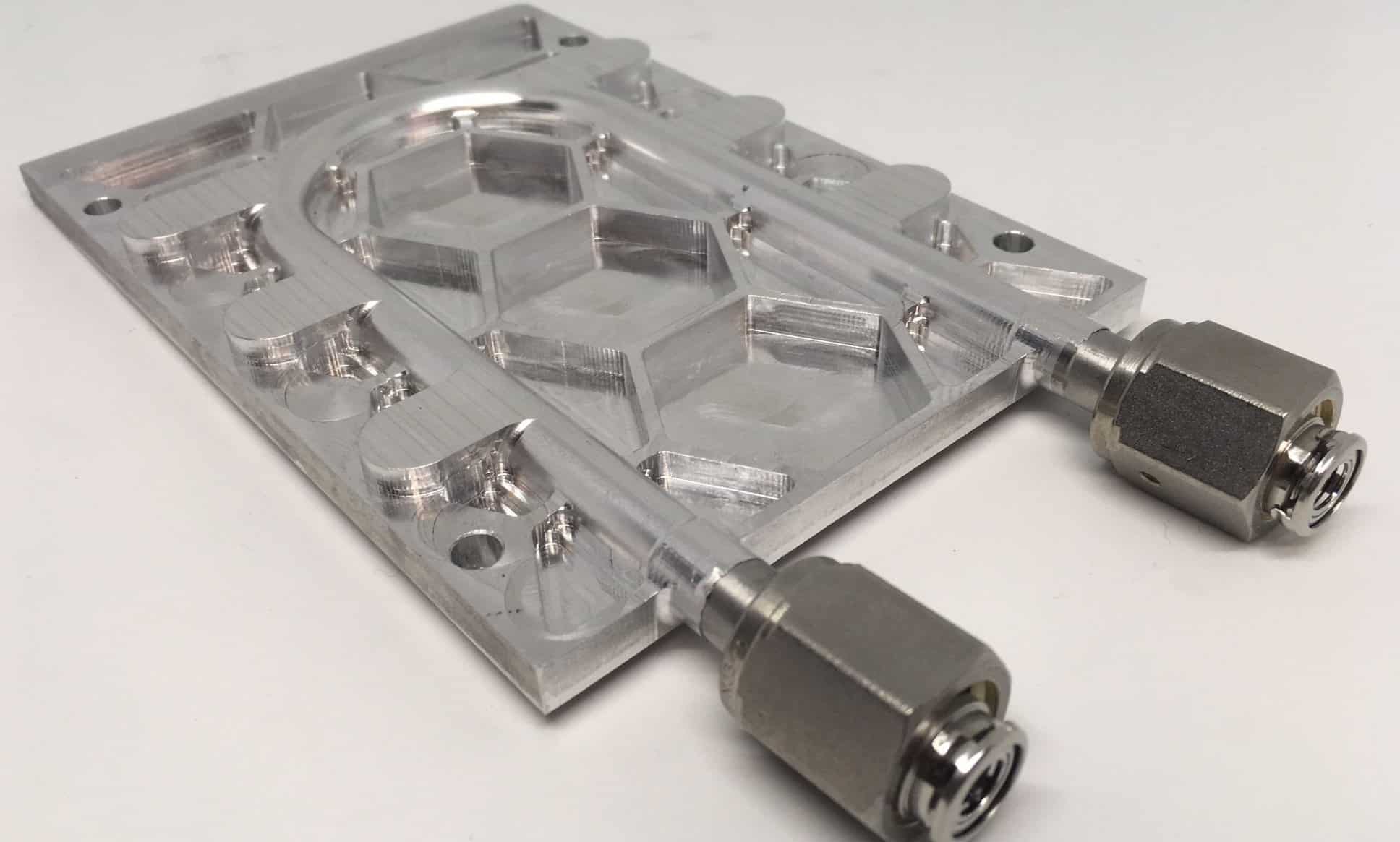

Fabrisonic also forged its close relationship with NASA, and their jointly developed 3D printed heat exchanger device passed the aerospace quality control test in 2018. Recently, the company and optical sensor experts cooperated with Luna’s innovative sensor project for NASA. The project aims to collect data on cryogenic fuel pipes for the rocket test rig at Stennis Space Center.

In the latest collaboration between NASA and Fabrisonic, the latter has further developed its UAM process to print composite metal coatings, which may be used in aerospace in the future.

Better use of amorphous metals

Amorphous metal or bulk metallic glass (BMG) is formed by rapidly cooling the alloy to bypass the crystallization stage of solidification. As a result, the materials have a unique disordered structure, and they have higher strength than conventional crystalline alloys.

BMG can also withstand greater reversible deformation than other metals, and they lack long-term periodicity, so they are also more resistant to corrosion. Although amorphous metals clearly have advantageous manufacturing characteristics, they have previously proven difficult to combine with other materials and difficult to print in thicker layers.

Fabrisonic worked with NASA’s partner LM Group Holdings (LMGH) to try to overcome these limitations by using its UAM 3D printing process to fuse amorphous metals with other alloys. The company proved the feasibility of the process by adding several different amorphous alloys and studying the reactions to better understand the interface composition.

During the test, the research team found that the low temperature of UAM made the bond of dissimilar metal alloys almost no intermetallic formation without reducing its high strength characteristics. The two companies also discovered that multiple passes can be used to add more metal, which in turn allows the thickness of the structure to be tailored to the end-use.

According to the paper, low ductility is usually a problem with existing crystalline alloys, but considering that UAM is compatible with multiple materials, it can add more ductile metals to the mixture. Similarly, traditional welding techniques limit BMG to specific geometries, but evaluations show that UAM can now be used to achieve more complex 3D shapes at a lower cost.

Overall, in the first phase of NASA’s development plan, the partners managed to incorporate crystalline metals such as aluminum, titanium and steel to produce parts with a wall thickness of 1mm. In the future, 3D printing technology can be deployed in the creation of laminates for heavy equipment or insulated oil and gas pipelines.

The two companies stated in their paper: “LMGH and Fabrisonic can provide a generation of products and services that are more advanced than the current state-of-the-art technology.” “Significant advantages in substrate protection, extended service life and improved application efficiency are provided. Market leverage.”