Electron Rocket, produced by a California-based aerospace company Rocket Lab, has been elevated to its launch pad before the company is about to perform its mission with the US Space Force.

The rocket, powered by a 3D printed Rutherford engine, has passed initial system tests and launched its launch site at Spaceport in the Mid-Atlantic region in Volops, Virginia last week.

In a mission originally scheduled for the third quarter of 2020 and coordinated by the US Space Force, Rocket Lab will launch microsatellites into space from the Monolith program of the US Air Force Research Laboratory. The purpose of this mission is to determine the ability of small satellites to support large-caliber payloads and monitor space weather.

“We’re proud to be partnering with the U.S. Space Force for the first mission from Launch Complex 2 and we’re honored to be working with them again following previous STP missions out of Launch Complex 1,” said Peter Beck, Rocket Lab founder, and Chief Executive.

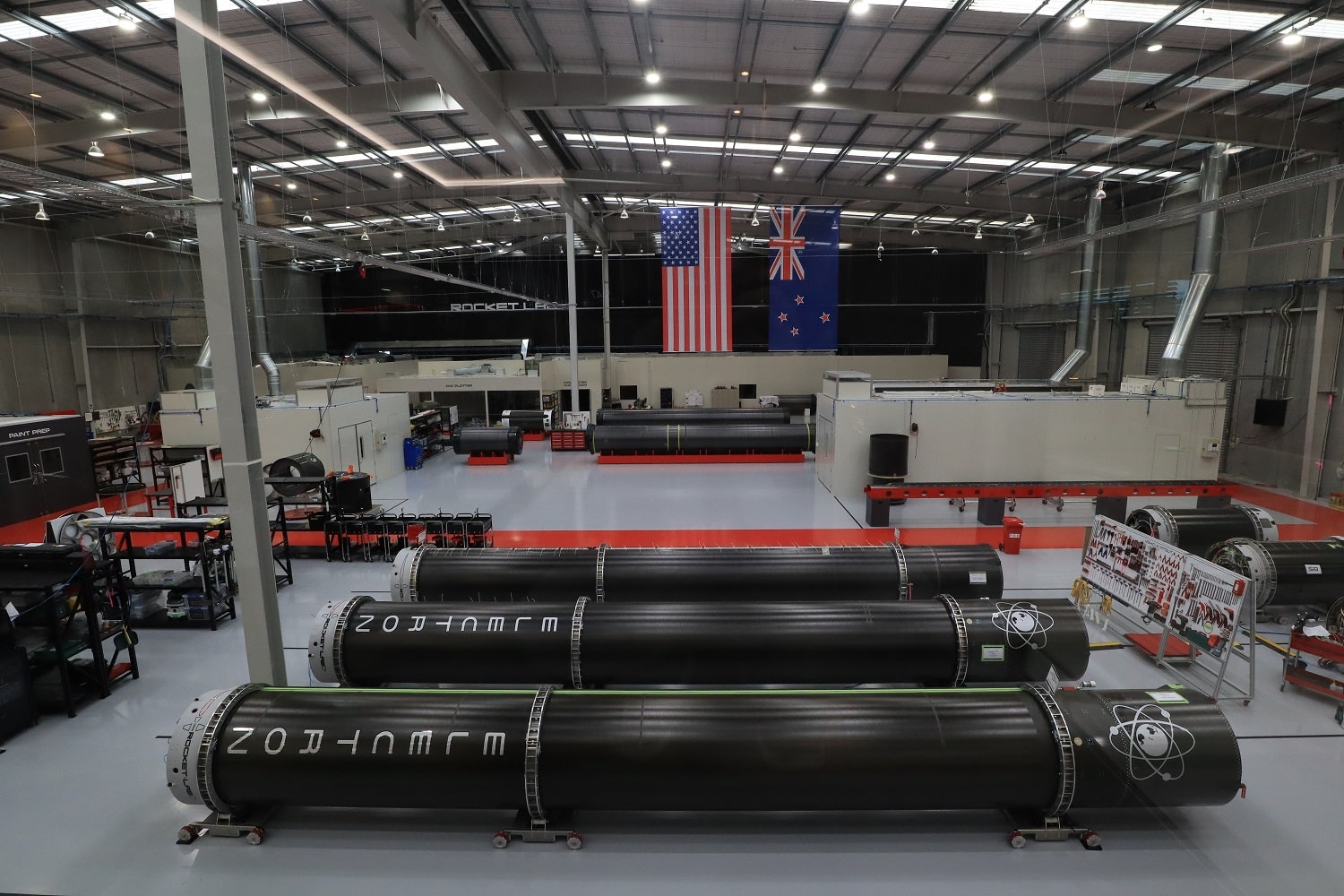

Rocket Lab’s Electronic Carrier Rocket

The mission of Rocket Lab, established in 2006, is to provide commercial customers with fast and repeatable small orbit satellite launches. The company successfully launched a rocket named “Tea” in 2009 and launched an electronic launcher (two-stage launcher) as its successor.

The company launched the Electron rocket for the first time in May 2017. After successfully taking off from the New Zealand base, a small vehicle called “It’s a test” landed on the track. If successful, the latest mission will be Rocket Lab ’s 49th launch of small satellites into space.

Electron Rocket ’s nine engines are powered by 3D printed liquid propellants, which are produced using electron beam melting (EBM) technology and are capable of 120N thrust. It is made of carbon composite material and can carry a payload of 225 kg, making it ideal for transporting small satellites.

In order to continue to develop the engine, Rocket Lab received another $ 140 million in funding in November 2018, making the company’s valuation exceed $ 1 billion. Since then, the company has celebrated the 100th 3D printing of its Rutherford rocket engine and is considered the cornerstone of the company’s pursuit of private space exploration.

All systems are suitable for 3D printer-driven rockets

In addition to conducting ground system inspections at the launch site, the Rocket Lab ’s team of engineers and technicians successfully conducted a series of comprehensive system inspections to verify the rocket ’s launch system.

The tests included raising the rocket to the launch pad, activating and adjusting its platen fluid system, power and communication checks, RF testing, and thermal ignition testing of the Electron Rocket 3D printing engine.

In one of the final stages before launching, NASA will need to certify the Rocket Lab ’s Automatic Flight Terminal System (AFTS). The fully automatic GPS system is designed to terminate any non-nominal flight. By reducing the reliance on ground assets and human flight terminal operators, this can increase the transmission frequency and provide better schedule control. The system has already conducted several missions at the launch site 1 of the Rocket Lab in New Zealand, and NASA hopes to certify the technology before the rocket ’s launch window in the third quarter of 2020.

Now, with the completion and commissioning of Launch Complex 2, the next phase of the US Space Force ’s satellite launch mission will be to complete the construction of the nearby Rocket Laboratory integration and control facility. This will include a launch control center, payload integration facilities, offices and pre-start integration areas for multiple electronic vehicles.

Additive manufacturing and rockets

Because additive manufacturing has the ability to produce complex parts in a cost-effective manner, it has found wide applications in research and development throughout the aerospace industry.

For example, the European Space Agency (ESA) has completed the first thermal test of a full-scale 3D printed rocket engine called BERTA (Biergoler Raumt transporta engine / Biergoler space transport drive). The engine was developed by Ariane Group at ESA and uses selective laser melting (SLM) made of nickel-based alloys (for injection heads) and stainless steel (combustion chamber).

Florida-based space company Rocket Crafters Inc (RCI) won a US $ 542,600 research contract from the Defense Advanced Research Projects Agency (DARPA) in July 2017 to develop its hybrid 3D printed rocket engine. Using proprietary direct digital advanced rocket technology (D-DART), Rocket Crafters aims to combine the advantages of 3D printed solid rocket fuel particles and liquid propellants to create engines with peak thrusts of up to 5,000 pounds.

Last February, German metal 3D printer manufacturer SLM Solutions produced “the world’s largest rocket engine.” The engine is manufactured on behalf of the British aerospace company Orbex, is 3D printed in a single piece, and will be used to put small satellites into orbit.