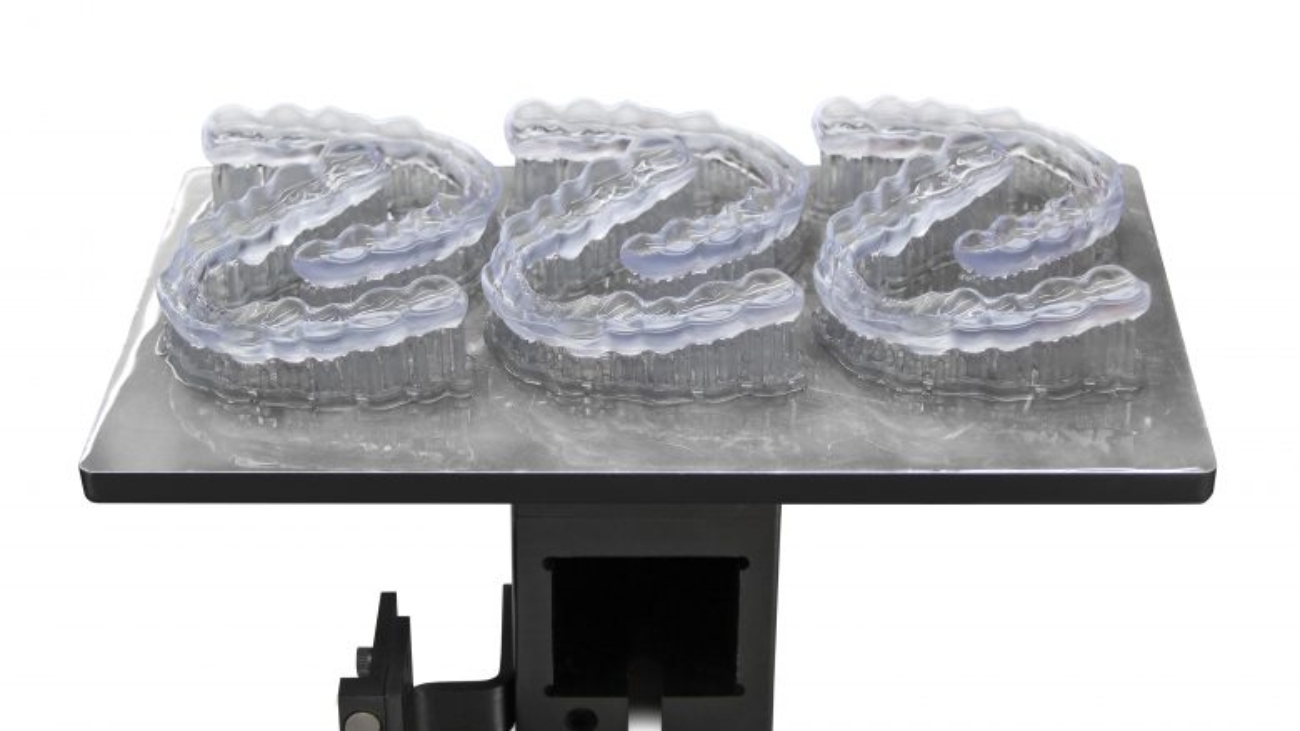

Desktop Health, a healthcare business within Desktop Metal Inc, committed to developing 3D printing solutions for personalized medicine, has received US Food and Drug Administration (FDA) 510(k) clearance for the company’s SmileGuard resin – a breakthrough light-curable, biocompatible material for the fabrication of strong and flexible bite splints and other orthodontic and dental appliances.

Among the previously-available 3D printed bite sprint solutions in the marketplace, the strongest materials are often uncomfortable to patients, while softer materials are often not as durable. SmileGuard resin solves this challenge.

After more than two years of development, SmileGuard resin now offers a superior blend of both strength and comfort, custom fit to a patient’s specific dental profile and needs. At the same time, it offers high-impact resistance to teeth grinding, clenching, temporomandibular disorders (TMD), and abrasions.

“Every year, dentists and orthodontists prescribe millions of bite splints or night guards to prevent patients from clenching and grinding their teeth, which can cause pain, headaches, sleep disruption, and also damage teeth,” said Ric Fulop, Founder, and CEO of Desktop Metal. “Made with traditional techniques, these devices typically require several steps and visits – from the time to diagnose, make an impression and manufacture, to the custom-fitting to the patient. Now dentists and orthodontists have a fast, easy, and reliable way to produce custom-made devices while the patient waits at the office. This is another milestone in dental innovation.”

Manufacturing on Demand

Traditional analog methods for manufacturing night guards require dental impressions that are sent to a lab to produce. At the lab, a splint is thermoformed on a created model, or it is milled out of a puck and checked on a model for fit. Then, it is polished and shipped to the dentist, with the complete turnaround time often averaging 2-3 weeks and requiring multiple patient visits.

With Desktop Health’s digital 3D printing workflow, SmileGuard resin can be used to manufacture night guards in as little as an hour, and be delivered to the patient the same day. The patient is scanned, in a matter of minutes, during an office visit, where easy-to-use software enables the device to be designed and printed. Polishing takes an additional few minutes to achieve the right shine.

3D printed bite splints and night guards are a fast-growing segment in digital dentistry and are one of the top three most common 3D printed dental applications. According to Desktop Metal, more than 45% of dental labs and clinicians are currently 3D printing bite splints and night guards.

SmileGuard resin joins a growing portfolio of Desktop Health dental solutions for both dental labs and dental professionals, including the Einstein 3D printer, designed specifically for dental professionals, and Flexcera FDA-cleared materials, for removable and restorative indications.

You might also like:

3D LifePrints’ EmbedMed platform achieves FDA 510(k) clearance:

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment