Engineers at the Max Planck Institute for Scientific Research (MPIE) in Dusseldorf and the Fraunhofer Institute for Laser Technology in Aachen combined old and modern technologies by developing a method of 3D printing Damascus steel.

If you want to have a longing in the eyes of sword fans in ancient times, please mention Damascus steel. Originally referred to as steel made from Woods ingots from India more than two thousand years ago, manufactured or traded in Damascus, it now refers to a type of all-steel, characterized by curved, wavy, light and dark band marks Like running water.

Since Wootz steel is no longer available, making real Damascus steel has become a lost art, but it is not unwilling for many scientists and craftsmen who try to reverse engineer existing examples. However, the basic idea behind it is well understood. If you go to a modern Renaissance exhibition, you will probably find many replica blades of unexpected quality in the swordsmith’s booth.

Damascus steel blades are made by bundling steel bands, heating them to heat, and then twisting them together. The blacksmith then hammered them, reheated, twisted, and hammered them until an intricate flow pattern appeared. The result is processed steel, which can be controlled by the blacksmith by controlling the carbon content to create tough, flexible steel for the sword core, which is then welded to another processed hardened, hardened and sharpened to form Steel on the blade edge.

Today, Damascus steel is usually made of two different grades of alloy steel, but it is still a more artistic process than art. Now, researchers are using 3D printers and lasers to bring Damascus steel into the 21st century.

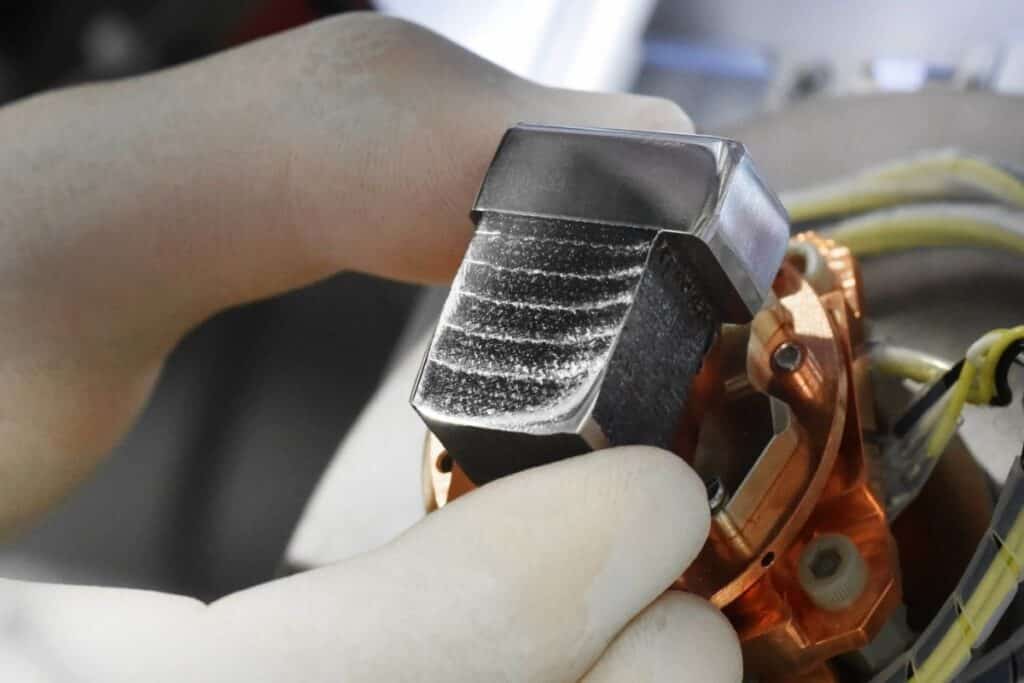

This new technology does not use two different materials to process to form a new alloy, but only uses one material-alloy powder of iron, nickel and titanium. Use laser melting to pour it layer by layer and melt the powder to form the desired shape. The excess powder is then removed to show the final product.

This is basic 3D metal printing, but the new technology differs in that the laser is used to change the crystal structure of the metal to form alternating layers of hard and ductile steel-a printed Damascus steel.

“We have succeeded in specifically modifying the micro-structure of the individual layers during 3D printing so that the final component has the desired properties – and all this without subsequent heat treatment of the steel.” says Philipp Kürnsteiner, a post-doctoral researcher at the MPIE. “Under certain conditions, small nickel-titanium micro-structures form. These so-called precipitates, harden the material. When subjected to mechanical stress, they hinder the movement of dislocations within the crystal lattice that is characteristic of plastic deformation.”

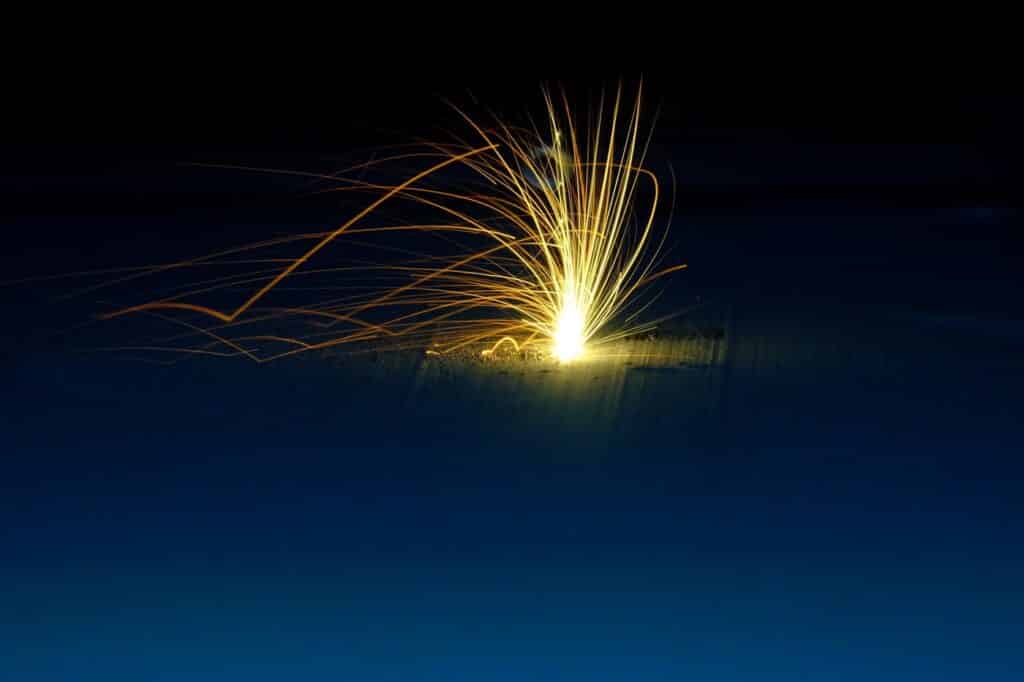

How the laser makes this change is a matter of time. After adding each layer, allow the metal to cool below 195°C (383°F). Leave a soft layer. In order to form a hard layer on top, the second layer of metal is added, allowed to cool, and then the laser is carried, thereby changing the structure and hardening it. The result is a combination of strength and ductility. According to the team, by changing the energy of the laser, the speed of the printing process, and other factors, the properties of the metal can be controlled quite accurately.

“The technology opens new doors for adjusting the local micro-structures in a defined manner during the additive production of even complex workpieces and making post-treatment unnecessary,” says Kürnsteiner. “Until now, it has been common practice to use conventional alloys in 3D printing. However, many known steels are not optimally suited for additive manufacturing. Our approach is to develop new alloys that can exploit the full potential of 3D printing.”