In its effort to always be one step ahead of mounting competition, the current construction 3D printing industry leader COBOD has released the first-ever construction 3D printer configurator app, available on iOS and Android as well as a web app on the company’s website. The configuration looks to make construction 3D printing more accessible and more fun, in the era of 3D Construction 2.0. It’s a blast.

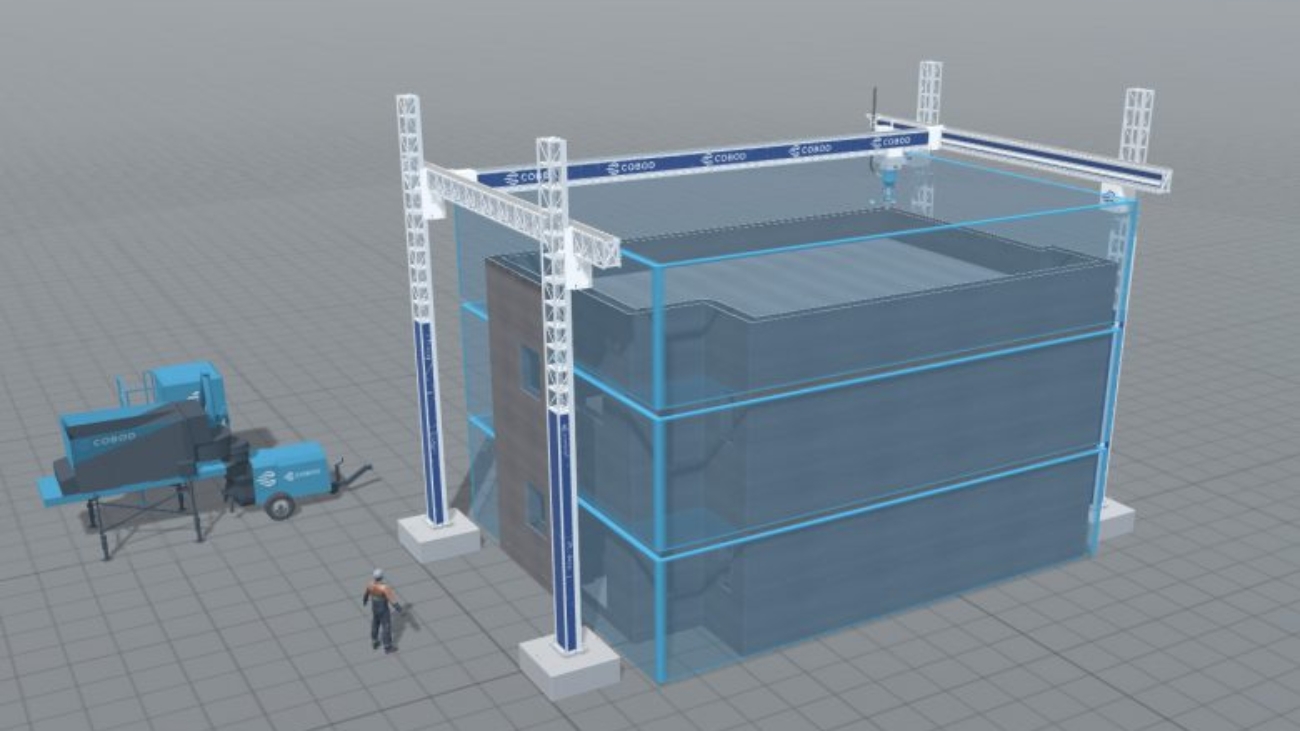

Users interested in the largest house 3D printer on the market are now able to configure and design their own printer to suit their specific construction needs. In the configurator, they will also find a detailed overview of how the construction site of the future looks. The company also integrated printing simulations of buildings of various sizes and shapes, from the very first BOD building to PERI’s 3D multi-story house in Germany.

The configurator can help to strengthen COBOD’s role as a segment and technology leader, working to broaden the market and bring automated conduction 3D printing to a wider than ever demographic. Playing around with the configurator makes anyone feel like they can really build a house at the touch of a button. That may not be the case now but it will be eventually.

Manufacturing on Demand

Users can start by configuring their 3D printer, modifying the width, length and height of the build volume. Interestingly, no one has yet created a similar configurator even for standard polymer 3D printers and it may not be a bad idea. Another interesting aspect is that the Z-axis for COBOD’s construction 3D printer is not measured just in meters but in floors. And still, another very fascinating element of the configurator is that the maximum possible length is 47.5 meters.

After setting up the printer, users can select a type of building from a library of models which reflect COBOD’s completed projects around the world. Once the model is selected, users can simulate the entire 3D printing process – even within a virtual neighborhood – accelerating the print speed to see the construction progress as it happens.

It’s really not that hard to imagine a future, not so far away, when this will be more commonplace and it will be possible to follow the construction of one’s own home project or a professional construction site, from the comfort of one’s home computer screen. Today it seems a bit far-fetched but less than a decade ago the idea of printing a house was not just far-fetched, it was borderline fantasy. Now construction 3D printing is shaping up into a real industrial segment and this is what COBOD means by 3D Construction 2.0.

You might also like:

3D Printing Technology takes center stage in Downtown Huntsville:

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment