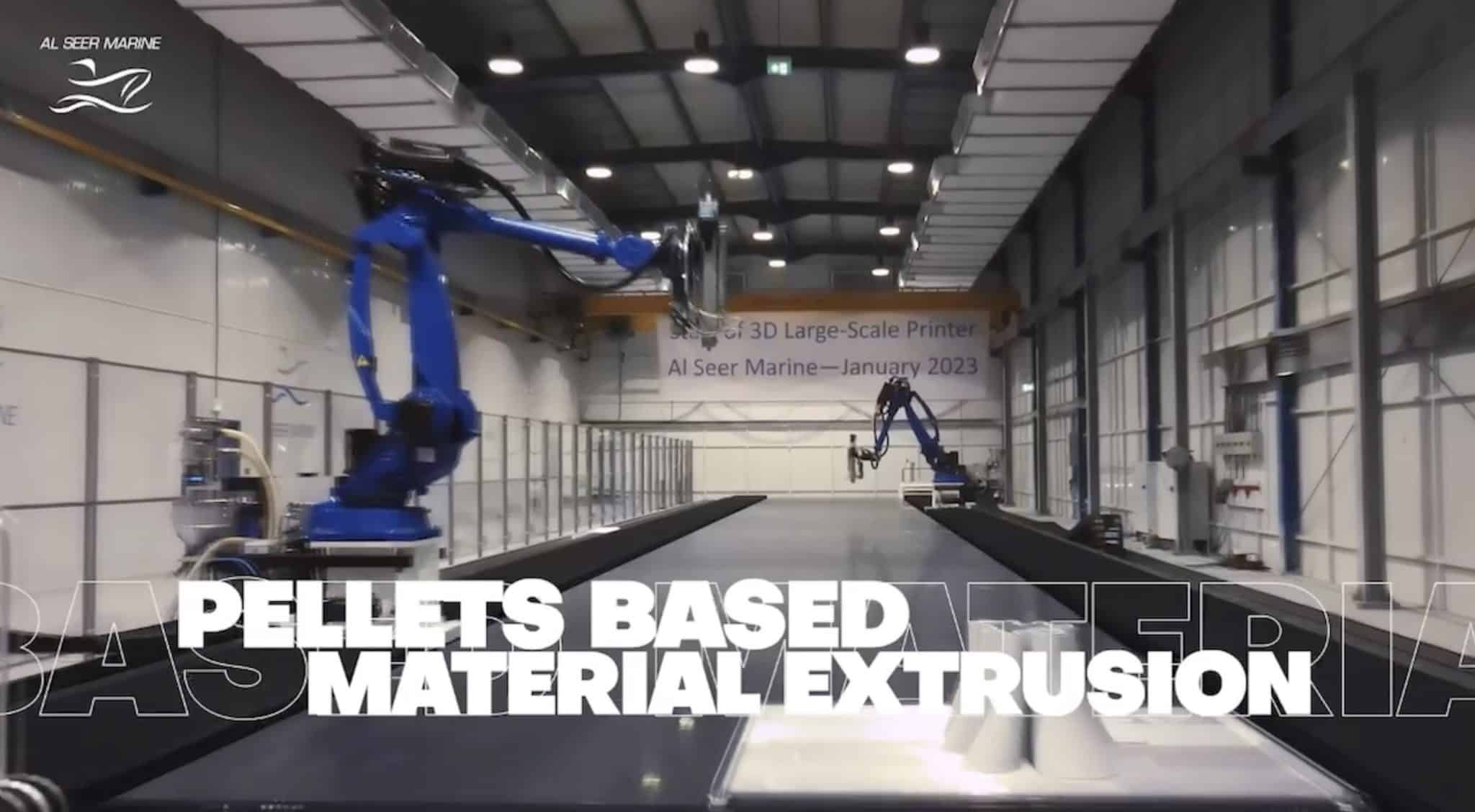

Sometimes a photo is worth a thousand words and this may be one of those times. Meet the Mega II, the world’s largest 3D printer, created by composites LFAM specialist CEAD for Al Seer Marine, the leading marine company in the Arabian maritime region, with a portfolio of services that range from yacht manufacturing to unmanned systems, boat operation and catering to all needs of marine operators and end-users.

The 36-meter state-of-the-art Mega II system can produce large-scale manufacturing complex designs from a small spare part to a large vessel, with unparalleled speed and precision. With Mega II industries such as maritime, aerospace, and rail can now push the boundaries of what’s possible, taking manufacturing to new heights. The power-packed pellet extrusion LFAM system, featuring two robots on rails, can produce lengths up to 36 meters and widths up to 5 meters, making it a game-changer for many industries.

Manufacturing on Demand

Al Seer Marine is aiming to design, build and manufacture vehicles and vessels using LFAM 3D printing technology, not only fulfilling global and regional demand but also preparing for future growth. Last year 3dpbm had the opportunity to visit CEAD and catch a first glimpse of the massive project, which takes the title of the world’s largest 3D printer from direct competitor Ingersoll/Camozzi.

As it became apparent in the early days of open extrusion 3D printing, the technology has no inherent size limit. Certain early technical limitations relative to material quality on large-size parts have been addressed through the introduction of fiber-reinforced composite materials, other concerns on part quality, dimensional accuracy and price still need to be addressed but the overall quality and accessibility of LFAM parts continue to improve, and grow, as shown by the Mega II systems in this case but also by other systems such as Caracol AM’s HERON.

While companies in traditional maritime countries are hesitant to abandon traditional manufacturing processes, newer companies in emerging maritime nations such as the UAE are fully embracing new opportunities offered by additive manufacturing. Since 2022, Al Seer Marine has been scaling up AM R&D through the integration of a dedicated team as well as the collaboration with CEAD. WIth the Mega II 3D printer, the project is already bearing the first fruit, and it looks like this is just the start of a new era for faster and more sustainable boat and yacht parts manufacturing.

You might also like:

What to consider when choosing a 3D printer nozzle: A long time ago the idea of a 3D printer nozzle for a FFF device was quite simple: it was a 0.4mm brass nozzle, hopefully with a thread pattern to match your hot end.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment