As a key 3D printing technology, SLM metal printing technology continues to gain the attention of scientific research and industry. At present, in China, traditional manufacturing companies are beginning to actively contact this technology. Compared with the domestic slowdown, foreign countries still have to lead ahead. In this issue, taking the manufacture of high-temperature fixtures as an example, we introduce the application of 3D printing in a material testing system (MTS).

Because some special industries have higher requirements for the mechanical properties of materials under ultra-high temperature, the existing tensile testing machine fixtures are mostly made of metal materials under pressure, and the yield failure phenomenon will occur prematurely during the high-temperature pressurization process… For example, when measuring the high-temperature creep performance (700 ° C) of IN718 alloy, standard steel fixtures are easily broken; besides, the accuracy and consistency of data cannot be guaranteed when performing performance tests on unstable fixtures. The testing of 3D printed parts that is inherently at risk of consistency is even worse.

To accurately quantify performance, researchers at the US Air Force Institute of Technology (AFIT) have redesigned MTS fixtures and manufactured them using SLM technology, which has a higher thermal conversion rate and reduced fixtures during high-temperature creep Thermal stress, thereby reducing the probability of cracking of the fixture.

Optimized design of MTS fixture

3D printing has advantages in manufacturing parts with complex internal structures. This advantage can be used not only in the manufacture of conformal cooling water channel molds but also in the manufacture of fixtures with cooling channels.

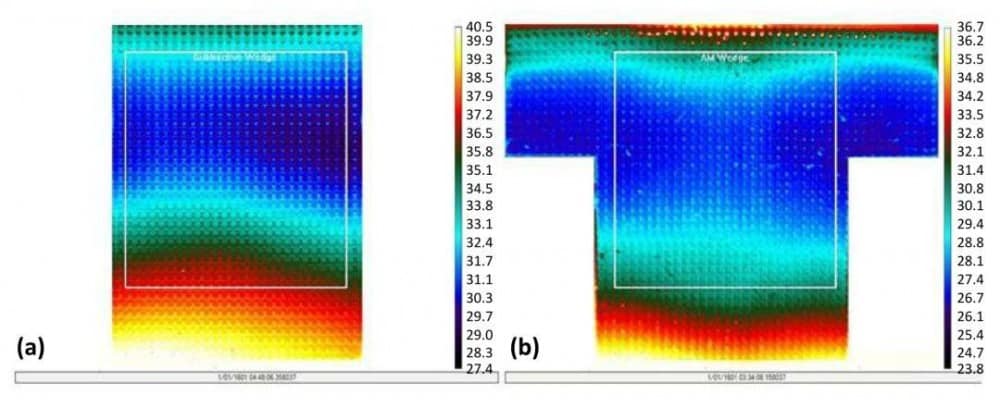

Optimized design: 3mm three-channel flow path on the left, and 5mm single-circuit flow path on the right

At first, the researchers designed a three-circuit flow channel with an internal diameter of 3 mm and found that the powder in the passage was not easy to remove. After optimization, it was improved to a single-loop flow path with a diameter of 5 mm, and the processing direction was also optimized to reduce the use of supports. The improved design powder is easy to remove, and also provides the most suitable fluid environment for experimental testing.

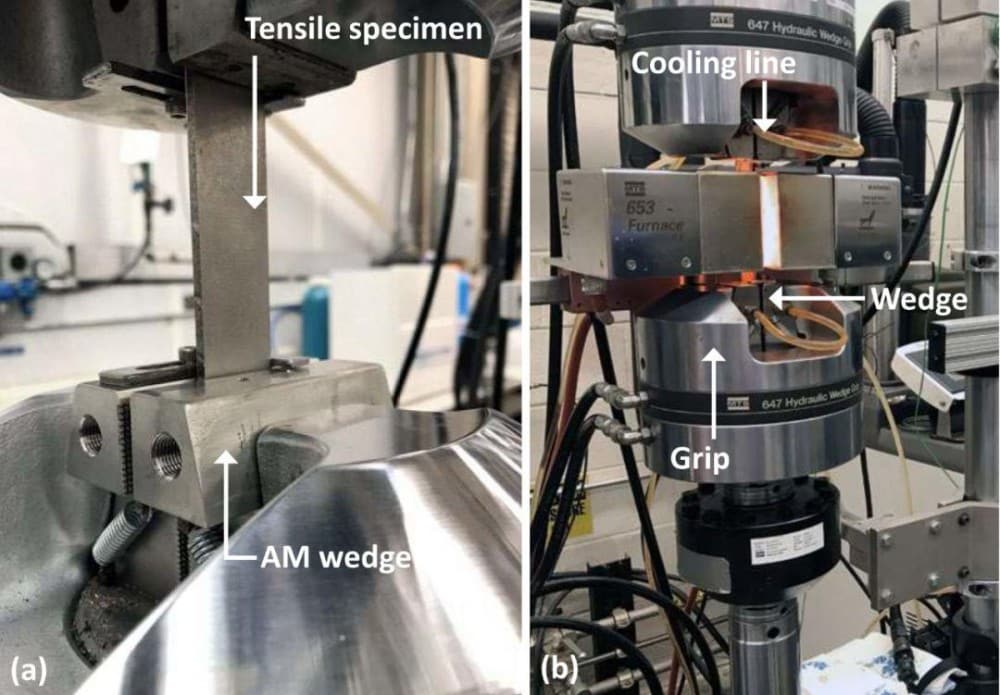

CFD simulation cooling

To compare the heat dissipation effects of 3D printing and traditionally manufactured MTS fixtures, the researchers simulated this. Import the two model parts into ANSYS Fluent software to calculate the enthalpy of the system based on the momentum, energy and continuity equation. The change in the total enthalpy is the heat dissipation effect of the system.

Simulation of the cooling effect

By comparing the temperature distribution of the two models, it is found that the 3D printed MTS fixture has a higher change in enthalpy value, which is 2.87 times that of the traditional process fixture, and the temperature distribution is more uniform.

MTS fixture manufacturing

The equipment used in manufacturing is Concept Laser M2 Cushing. The model has a margin of 4mm to compensate for the deviation when it is separated from the substrate. The substrate material is steel. The island scanning strategy is used for printing. The post-processing process includes wire cutting, surface grinding, and drilling at key locations.

SLM forming parts

Experimental test

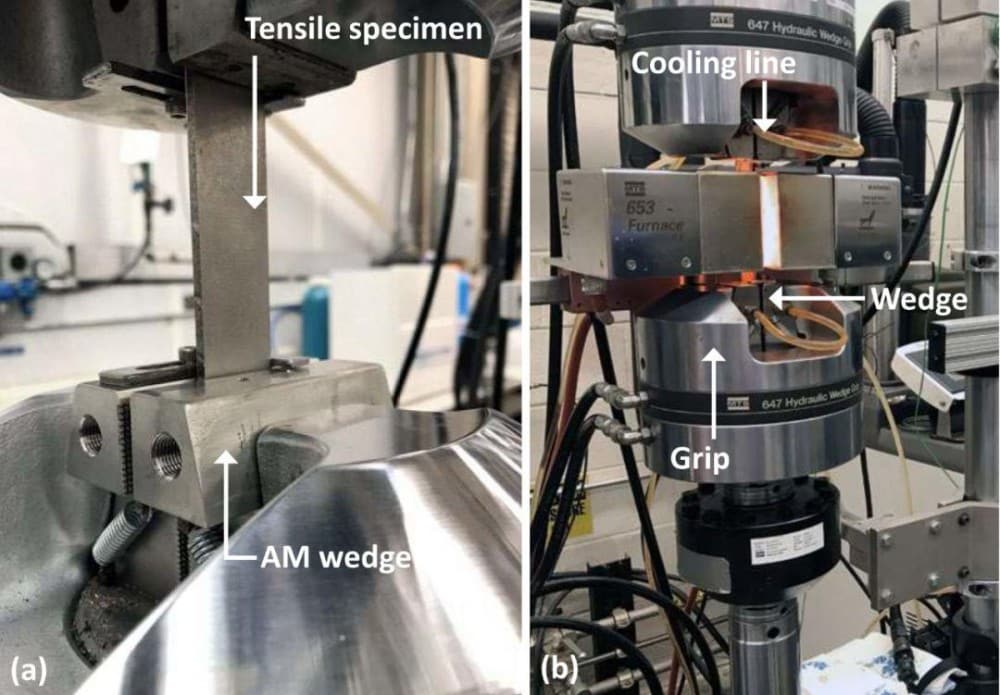

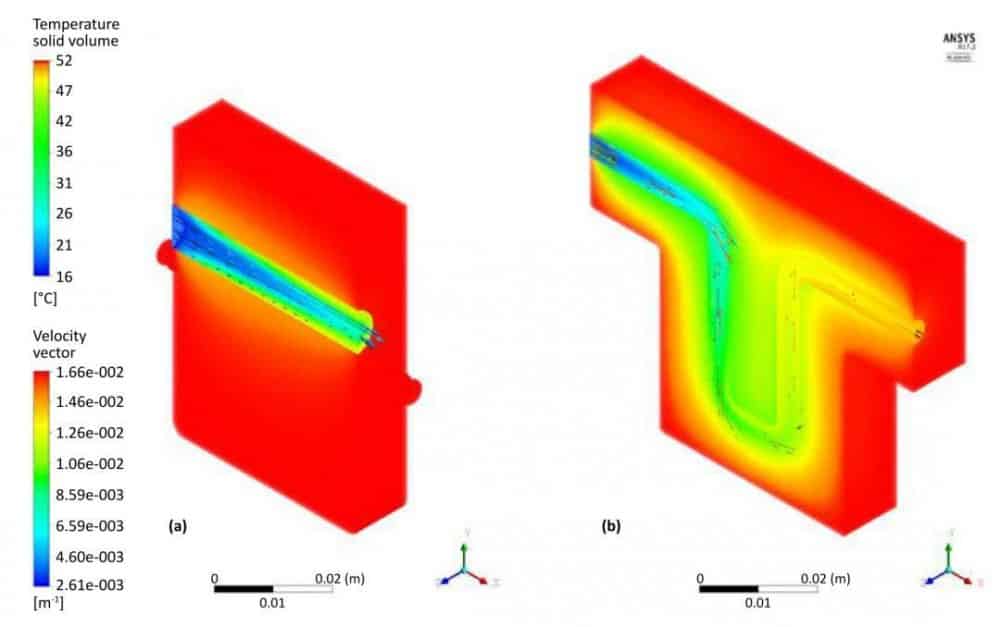

The AFIT researchers installed the SLM-formed MTS fixture on 22 KIP 810 MTS®, with deionized water as the coolant, a flow rate of 13.5mL / sec, a coolant temperature of 22 ° C, a clamping pressure of 6.8 MPa, a tensile force of 1000N, and creep The changing temperature is 700 ° C. During the creep test, the surface of the metal fixture was coated with Aeroglaze Z306, and the FLIR® SC7650 infrared camera was used to monitor the thermal images of 3D printed fixtures and traditionally manufactured fixtures.

Comparison of heat distribution: (a) traditional manufacturing jig, (b) SLM manufacturing jig

The results show that the 3D printed jigs have a better heat conversion effect. During the cooling process of the jigs manufactured by the traditional process, the average temperature is 31.7 ℃, while the 3D printed only 27.7 ℃.

Conclusion

The metal 3D printing conformal cooling water channel provides a wider design space for the mold, and this advantage can also be applied to other fields. AFIT researchers used the IN 718 MST fixture manufactured by SLM, which has very low thermal stress in high temperature creep testing, reducing the possibility of the fixture cracking under high temperature and pressure environments. To further improve the heat dissipation capacity of the cooling channel, a more complicated spiral channel is designed to create a turbulent environment and improve the efficiency of heat transfer. This design is also suitable for other similar applications.