Fast Radius, a Chicago-based digital manufacturing service provider, and Axial3D, a UK-based medical technology firm, have announced a new ‘DICOM-to-print’ service for surgeons and hospitals across North America.

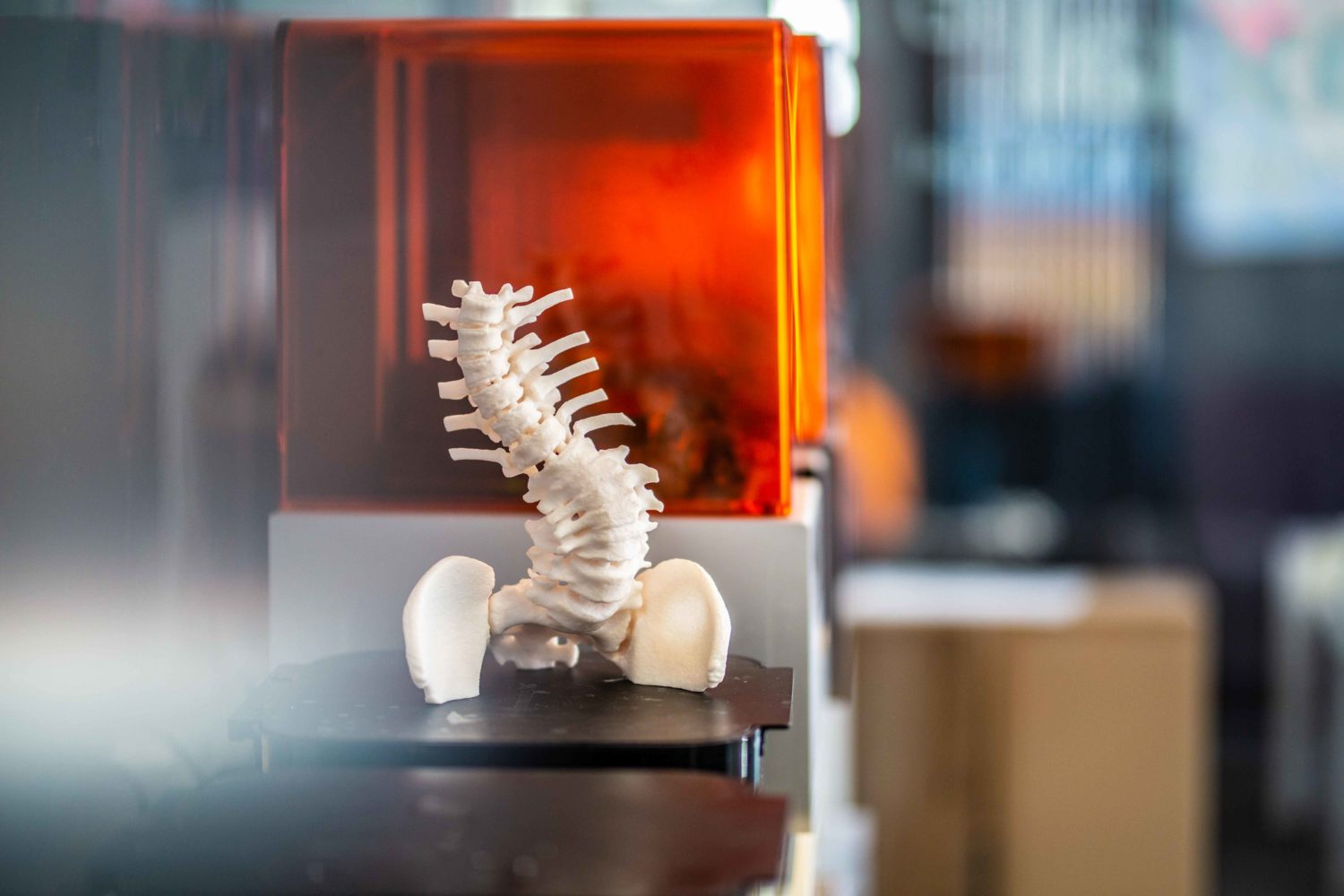

The partnership between the two firms is intended to provide clinicians across the United States, Canada, and Mexico access to improved surgical planning with micro-millimeter accurate, patient-specific 3D printed anatomical models. Derived from the patient’s own 2D scans, these models are reportedly shipped to surgical teams in as little as 48 hours.

Lou Rassey, CEO at Fast Radius, comments “Our mission at Fast Radius is to help companies make new things possible that advance the human condition. Partnering with Axial3D to make these surgical models will have a great impact on patient care. It’s work we’re proud to do.”

Increasing adoption of 3D printing in healthcare

Axial3D is a medical manufacturing service provider headquartered in Northern Ireland. The firm was founded in 2014 to help healthcare providers adopt 3D printing. Having partnered with the likes of Formlabs and value-added reseller GoPrint3D, Axial3D’s activities include supplying hospitals with the equipment needed to set up managed, point-of-care 3D printing labs. The company also has on-demand manufacturing services for medical professionals.

Axial3D’s specific area of expertise is centered on the production of anatomical models for use in pre-surgical planning, medical training and patient communications.

In 2019, Axial3D closed a $3 million funding round to extend its 3D printing software and services in healthcare across the U.S. It also supplied an on-site 3D printing lab to Newcastle Hospitals NHS Foundation Trust in the UK.

Furthermore, earlier in 2020 the company partnered with Durban-based service provider MedTech3D to ensure affordable access to high-quality 3D printed models in South African hospitals.

Manufacturing on Demand

Advantages of 3D printed models

The advantages of 3D printing mean that clinicians can gain access to a new standard of insight into the patient’s anatomical detail, a step above what is currently possible when simply relying on 2D imaging.

3D printed models can be held in the surgeon’s hands and fully assessed – allowing them to tangibly define and even practice a surgical plan before they set foot in the operating room, potentially improving surgical performance and patient care. As such, this helps to increase the confidence of clinicians when creating precision surgical plans. Indeed, anatomical models are a key application for 3D printing in the medical sector, with its adoption in this regard has increased significantly over the years.

DICOM, short for Digital Imaging and Communications in Medicine, is the international standard for the communication and management of medical imaging information and related data. The new DICOM-to-print service from Axial3D and Fast Radius aims to provide 3D printed models at a critical time for hospitals across the United States, as they look to restart surgical services in the wake of the COVID-19 pandemic, where there remains a backlog of surgical procedures to tackle.

Roger Johnston, CEO at Axial3D, states “The partnership between Fast Radius and Axial3D comes at a critical time for healthcare institutions. We are now able to support surgeons and hospitals in the US minimize the impact of COVID 19 as they endeavor to return elective surgery capacity.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Anas Essop

Leave A Comment