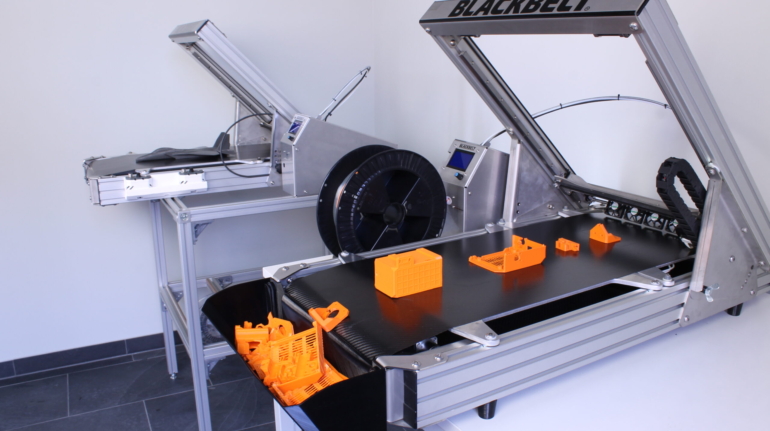

Blackbelt 3D Launches Continuous FDM 3D Printer for Large Parts 3D Printer Hardware

New 3D printing market entry BlackBelt 3D launched a new type of industrial production machine:The BLACKBELT 3D printer brings new standards to the 3D printing industry including the ability to print continuously one part after the other, print extremely long parts, and print specific designed overhangs without additional support material.