Don-Plast Uses VSHAPER GO 3D Printer for Prototyping of Decorative Goods Industrial Additive Manufacturing

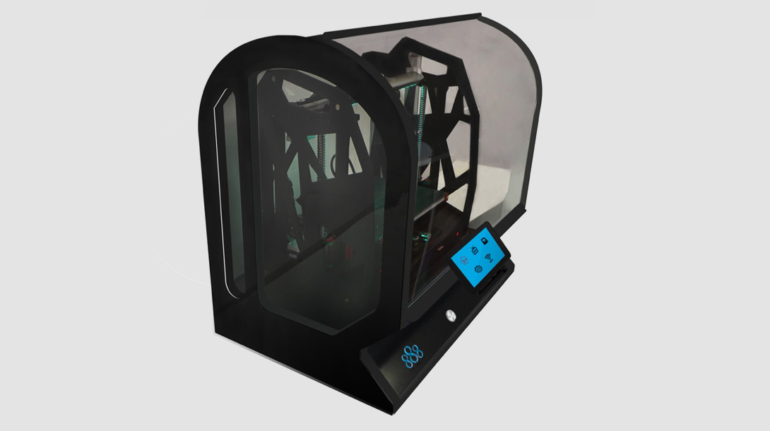

Don-Plast is one of Poland’s leading manufacturers of plastic decorative goods used in designing flats, gardens and balconies. The company continues to expand its customer base by attending international horticultural and landscape architecture exhibitions presenting interesting shapes of flowerpots, bowls and vases. Their production has been supported for some time by the VSHAPER GO 3D Printer.