Luxexcel and IFB Solutions Sign contract for the First Ophthalmic 3D Print Platform Consumer Products

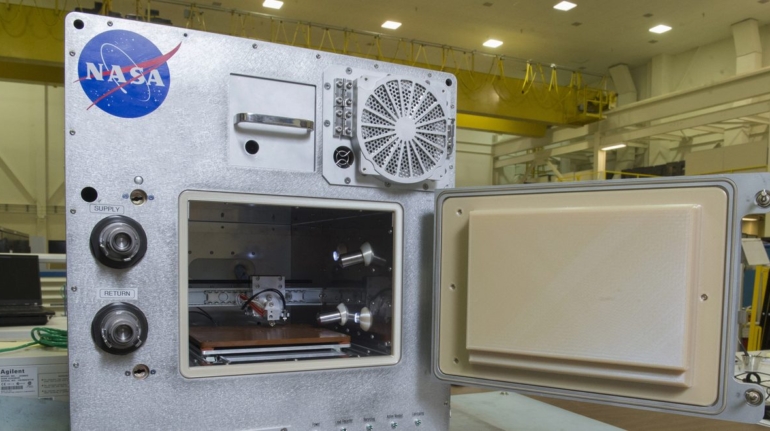

Luxexcel and IFB Solutions have signed a contract for the first 3D print platform for ophthalmic lenses. The platform will be integrated into IFB’s optical operations in Winston-Salem, N.C. which is one of the top 10 independent labs in the country. The Luxexcel platform consists of industrial grade optical 3D-printers, lens-design software and workflow integration tools which enable customers like IFB Solutions to manufacture 3D printed ophthalmic quality lenses that meet all industry standards. The technology is initially focusing on difficult-to-manufacture medical specialty lenses.