Fill Machine Engineering has developed a new low-pressure casting process. Before the die ingress, the magnetic field and short-circuit current at the end of the riser facilitate the precise low-turbulence process of casting aluminum.

Cast aluminum parts have huge potential for light construction. New methods for the production of sand molds and cores enable increasingly complex cavities and casting structures. In addition, there is a trend of electric vehicles in the automotive industry. New castings are entering mass production. Fill set the goal of optimizing the low-pressure casting technology successfully established in the market.

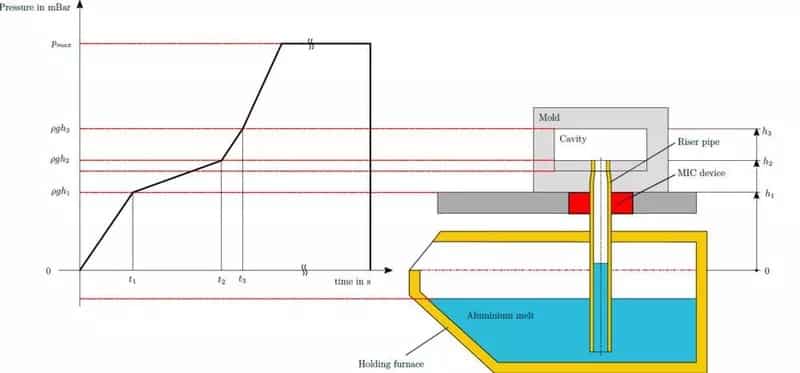

Innovation comes from successful development projects aimed at improving the control and regulation technology of low-pressure casting machines. At the same time, the potential to reduce the filling speed when molten metal enters, that is, active braking was evaluated to achieve smoother filling according to the shape of the cavity. The pressure curve changes the bathwater level according to the height relative to the stove. The drop in the molten pool water level must be compensated in the control system. The filling level and the rate of pressure increase relative to the cross-section produce a volume flow that occurs as soon as the molten metal is forced to flow upward by the overpressure in the furnace. Therefore, the expansion of the cavity results in an increase in the aluminum transported through the riser.

If the molten metal level remains constant, the flow rate increases. Therefore, the expansion of the cavity, especially after the sprue bushing, can cause a significant increase in the flow rate in the riser. This increase causes turbulence in the molten metal. In order to achieve particularly low-turbulence mold filling, the molten metal must be actively decelerated. Experienced casters believe that cast screens that prevent oxides are also particularly good at slowing down molten metal. This means that the cast screen can be equivalently understood as a mechanical baffle. However, the cost of the screen in the low-pressure casting process is due on the one hand to the screen itself, on the other hand to the automation of the screen setting, and subsequently to the machine tool used to drill the screen. Depending on the material, the injected screen may melt in the returned waste. Otherwise, it must be discarded. The solution is an active flow damper that can be integrated into regulation and control technology. This means that if it is only used to decelerate molten metal, the screen can be omitted. This means that the cast screen can be equivalently understood as a mechanical baffle.

However, the cost of the screen in the low-pressure casting process is due on the one hand to the screen itself, on the other hand to the automation of the screen setting, and subsequently to the machine tool used to drill the screen. Depending on the material, the injected screen may melt in the returned waste. Otherwise, it must be discarded. The solution is an active flow damper that can be integrated into regulation and control technology. This means that if it is only used to decelerate molten metal, the screen can be omitted. This means that the cast screen can be equivalently understood as a mechanical baffle.

Braking Effect of Eddy Currents in Molten Metal

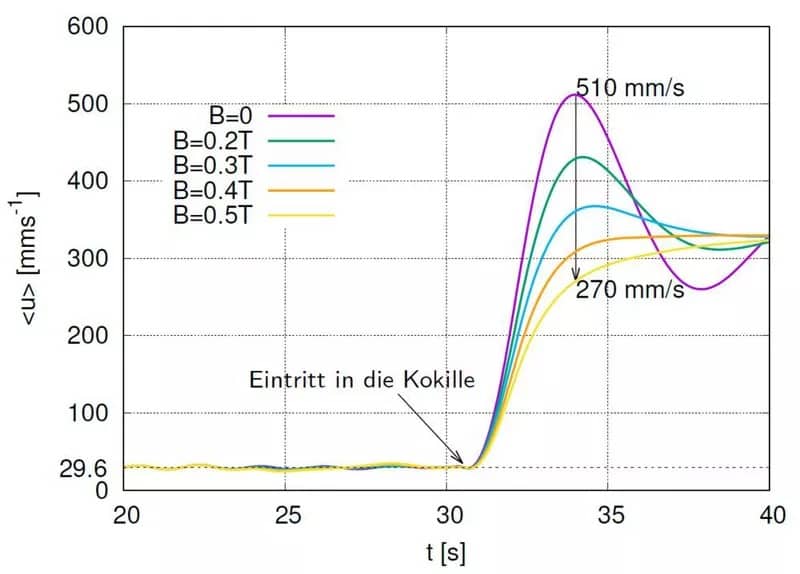

Moving an electrical conductor (aluminum in this case through a magnetic field) will cause eddy currents in the conductor, slowing down the molten metal due to the opposing magnetic field formed. The effect of this eddy current brake depends on the speed. If the flow rate in the riser increases, the braking effect will also increase. When the cross-section of the cavity changes significantly perpendicular to the filling height, the magnet box will decelerate the molten metal, resulting in low-turbulence mold filling. This effect is self-adjusting and can be filled with low turbulence, without having to consider the complicated pressure curve that must be adapted to the cavity. In addition, the magnet box can compensate for errors caused by the offset of the pressure curve due to the different filling volumes. For example, changes in furnace geometry and molten metal drawn from the casting can cause pre-compression and level deviations. This will move the pressure change points vertically and shift them away from the pressure point in the casting system. The magnetic field is controllable. This means that it can be activated and changed in field strengths from 0 to 500 mT. This possibility makes it possible to influence the casting process in a targeted manner. In order to obtain a certain braking effect and casting process, permanent magnets can also be used. This option offers great potential for mass production of identical or similar castings. Figure 2 shows the decrease in flow rate in the riser at a constant rate of pressure increase. The input of the mold is displayed on the time axis. The riser with an inner diameter of 60 mm expands into a cavity with an inner diameter of 200 mm. The magenta line B = 0 indicates overshoot, and at a constant pressure increase rate of 7 mbar/s, the average flow rate in the riser increases to more than 500 mm/s. Under the activated magnetic field, the braking effect causes the maximum speed to be reduced to 270 mm/s without any overshoot.

Short-circuit Current

In addition to the eddy current braking caused by the magnetic field, Fill’s magnet box is also designed to allow short-circuit currents transverse to the magnetic field to pass through the molten metal. In addition, the current density caused by the short-circuit current is perpendicular to the magnetic field, which greatly improves the braking effect on the molten metal.

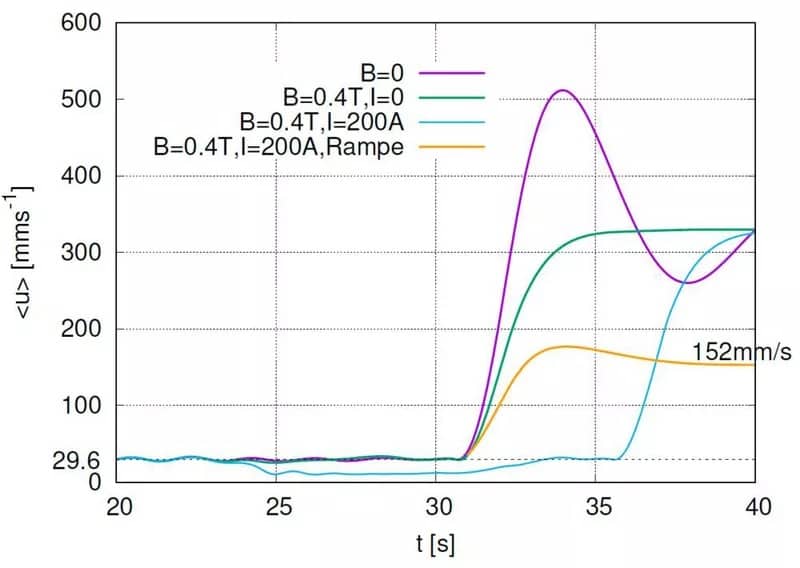

The ideal braking effect under short-circuit current is shown in Figure 3. Due to the magnetic field (blue line), the permanently applied short-circuit current will cause a time lag in the braking effect. On the other hand, if the short-circuit current increases linearly from the die entrance to 200 amps, as shown in Figure 3 (orange line), a greater braking effect will be produced, which can be activated by the magnet box. This technical design allows magnetic flux density up to 500 mT and short-circuit current up to 400A.

Simulation of the New Process Parameters

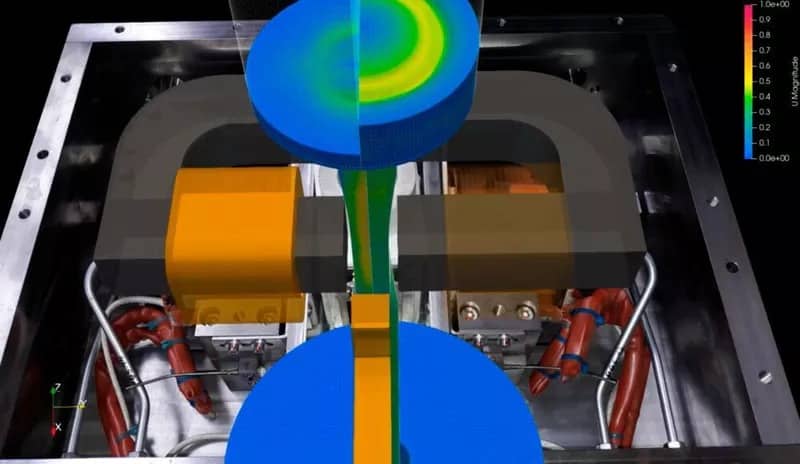

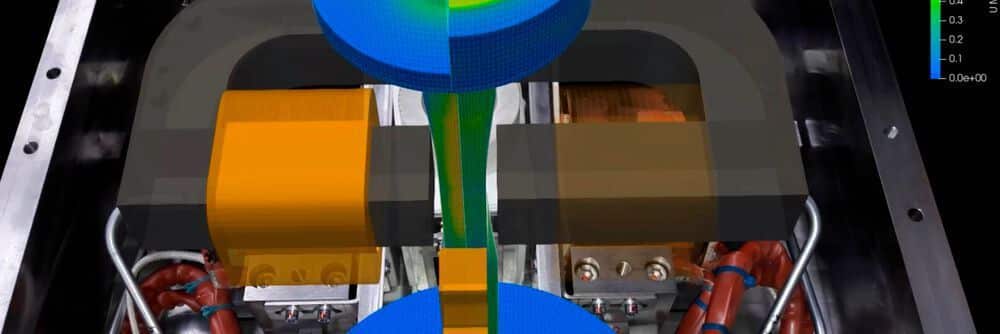

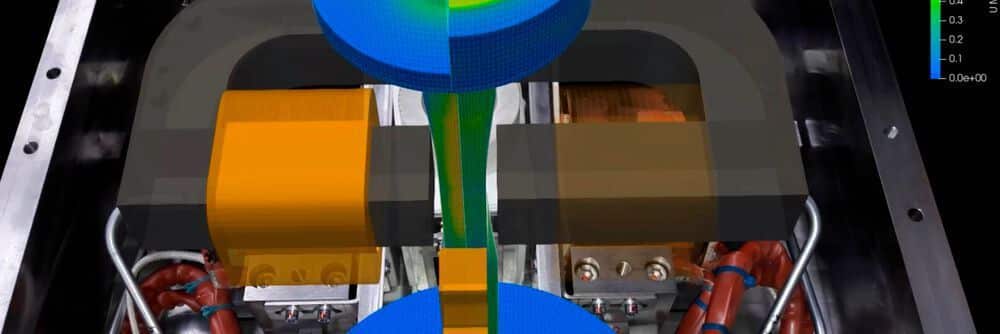

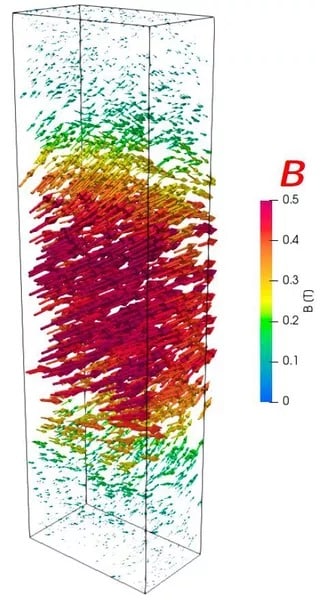

Due to the new magnetic field strength and short-circuit current process parameters and their adjustments, in addition to the pressure increase in the new electromagnetic induction casting process, a simulation of the magnet box has been developed. The HZDR Helzholtz Center in Dresden-Rossendorf uses OpenFOAM as the basis for the development of magnetic fields and short-circuit currents. Figure 5 shows a simulation of the casting process in a cylindrical cavity. The left side shows the braking effect and the right side shows no braking effect. Process parameters can be optimized through simulation. You can use this tool to optimize components that indicate oxide inclusions or critical areas in a fill simulation. The purpose of the magnet box is to improve the existing products and increase the quality rate. For new products, the simulated casting process can be improved by virtual testing and determining the best casting parameters.

Benefits, Environmental Impact, and Outlook

Combined with higher technical system quality, the following benefits can be expected:

- Higher part quality and less waste

- More efficient use of resources

- Reduce consumption of auxiliary materials (for example, due to the omission of large screens)

- Optimized control technology

The magnetic box is currently being further enhanced to act as a sensor to provide data on the actual filling speed. This means that in addition to regular machine data, it should also be possible to obtain a detailed understanding of the actual process through the production of data collection. SRI doo in Slovenia can use a fully equipped low pressure filling casting machine equipped with a magnet box for testing and small casting operations. Thanks to the innovative technology, the independent research center Access eV (Aachen University of Technology) also cooperates with Fill. The focus here is low-pressure casting in complex precision casting molds. This kind of planned cooperation, especially in the integration of digital simulation tools, has great potential.