3D printed device shows promise for treating Parkinson’s disease Research & Education

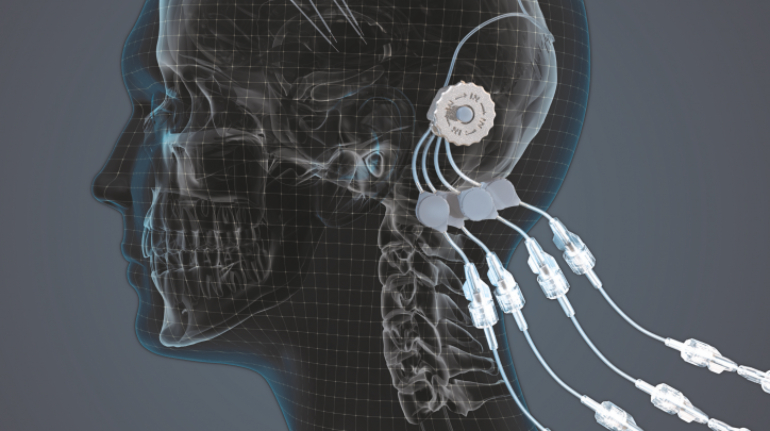

The impact 3D printing is having on life-changing applications is truly something to behold. Though the technology is not yet living up to the much-hyped expectations of 3D printed organs, it is still being used in a variety of ways to innovate within the healthcare sector. Metal 3D printing, for instance, has been leveraged to produce a new drug delivery system for treating Parkinson’s disease, which could be a game changer for the degenerative disorder.