Atomstack, a Chinese intelligent manufacturing technology company, released its Cambrian line of desktop rubber 3D printers, a first for desktop printing. The printers promise greater prototyping and faster production of customized rubber items.

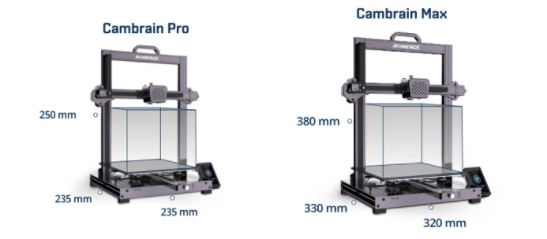

The company is marketing the new printer on Kickstarter, where it has raised over $500,000 HKD. The printer’s two versions, Pro and Max, are available for $339 and $379, respectively. The printers provide reasonable desktop build volumes, with the Pro sporting a 235 x 235 x 250 mm build platform; the Max can build up to 320 x 320 x 380 mm.

Manufacturing on Demand

The rubber that Atomstack uses for its Cambrian printers is highly elastic and resilient. These properties allows desktop printing a new range of products alongside typical plastic filaments like PLA, TPU, TPE, ABS and PETG.

Jason Li, Atomstack’s CEO, commented on the product launch:

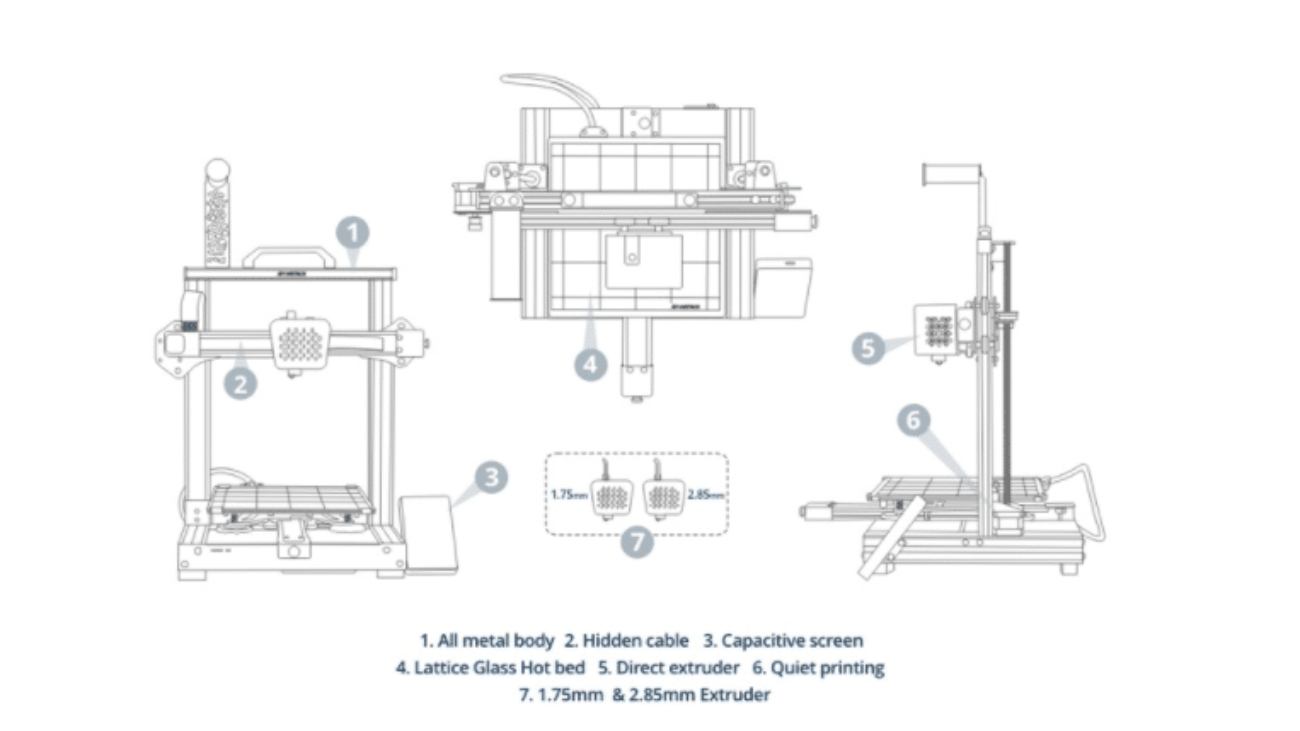

For years, the FDM 3D printing industry has been trying to develop a reliable way to print with rubber-like filaments. This has been difficult for a number of reasons including the fact that highly elastic filament materials are prone to jamming. To solve these problems, we had to rethink the entire process. We began by designing a new 2.85mm direct extruder design that eliminated nozzle jams, then we developed special rubber filament TPR (Thermo Plastic Rubber) with a high elasticity (50-70A hardness) and resiliency ( >50%) capable of accurately and reliably printing virtually any end-use rubber products.

You might also like:

Anycubic Photon Mono review: a new world of resin 3D printing: Shenzen-based Anycubic was founded in 2015 and has since become one of the most popular 3D printer brands in the market. The company now has nearly 300 employees. James Ouyang and Lu Ouyang, the current CEO, co-founded Anycubic after James received his Ph.D. from the University of Auckland. Aycubic’s first filament extrusion 3D printer, the Mega, came out in 2016. Now the company has four lines of 3D printers, including the Photon series of LED photopolymerization 3D printers and the newest line of 4Max Metal line of extrusion printers for metal filaments to produce green metal parts.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Adam Strömbergsson

Leave A Comment