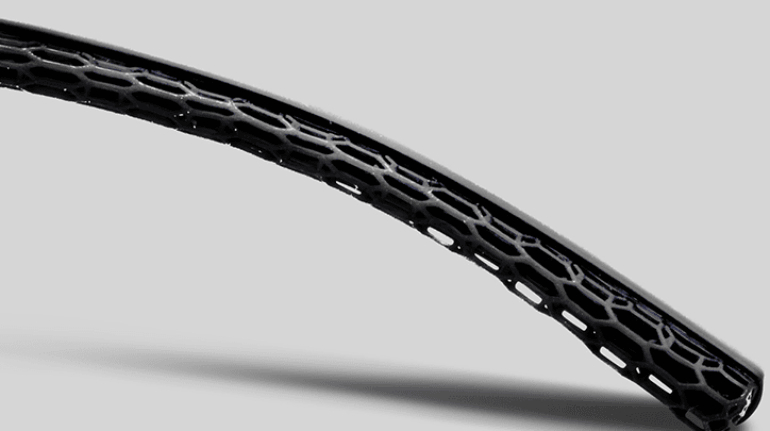

EOS launches Digital Foam Additive Manufacturing

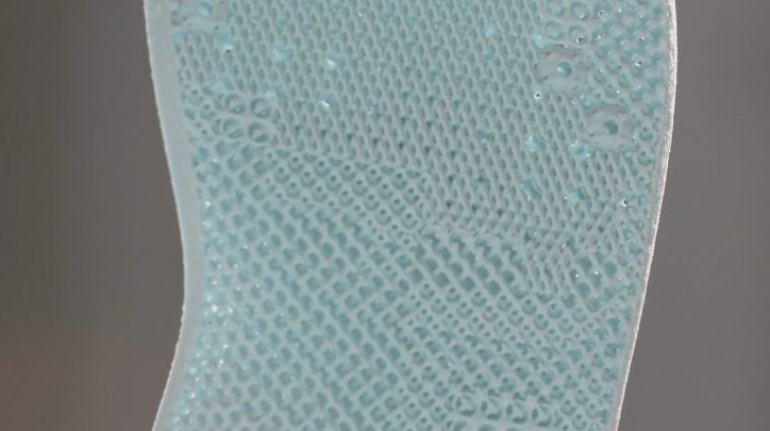

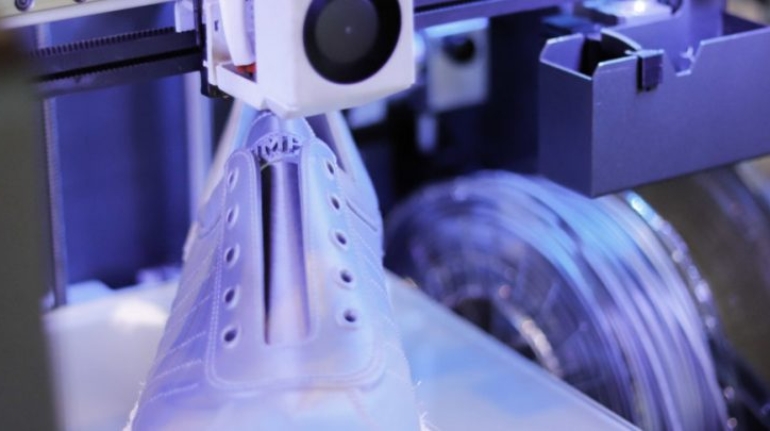

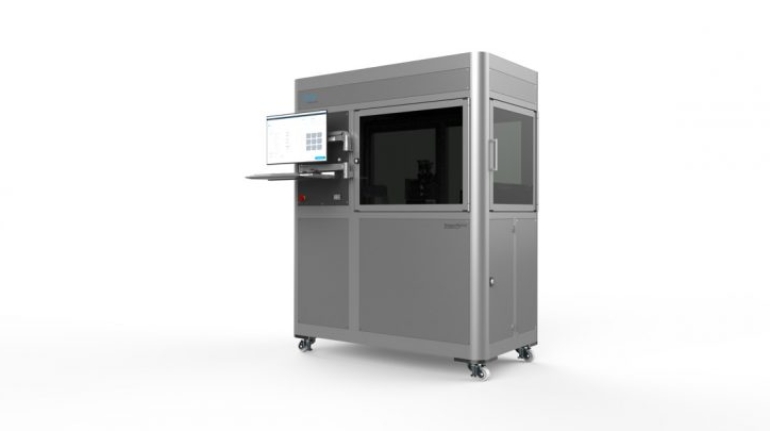

After nearly 80 years with minimal innovation, the foam industry is now employing 3D printing to produce products that are more comfortable, safer, lighter, and can be customized for each individual. Now EOS North America and its Additive Minds applied engineering team launched their Digital Foam program – a hub orchestrated by EOS connecting CAD, materials, part qualification, and additive manufacturing.