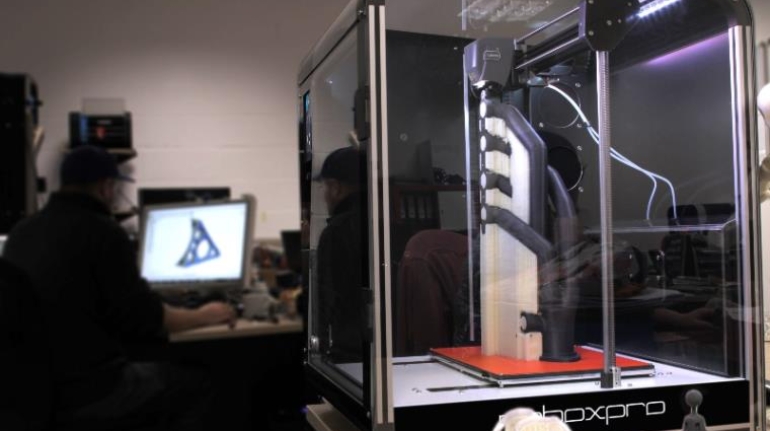

The People’s PPE Project Receives Government Grant to Scale Up 3D Printing of PPE for Jordan Refugee Camp

A project led by academics at the University of Sheffield and the University of the Arts London (UAL) has received £766,675 of government funding to scale up its delivery of personal protective equipment (PPE) to refugees living in Jordan’s Zaatari camp.