New AM Service Provider in India PRIMAEAM Installs EBM System

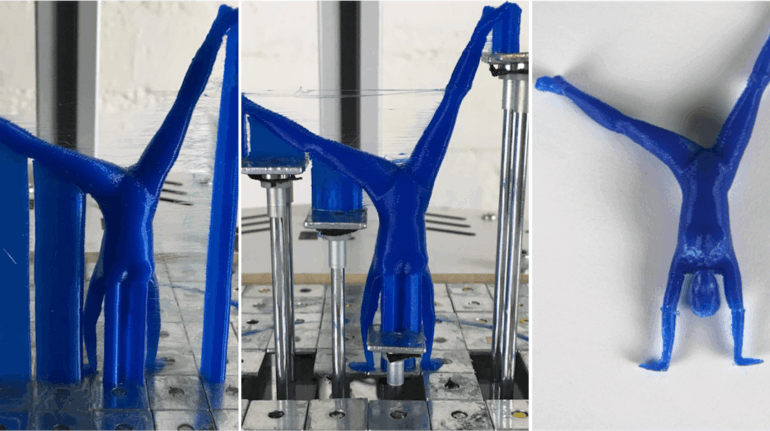

PRIMAEAM (pronounced as “PREMIUM”), a new entrant to Additive Manufacturing in India, is betting on GE Additive’s Electron Beam Melting technology. The company, which already provides polymer 3D printing services with FDM and MJF technology, just installed a new Arcam Q10 system.