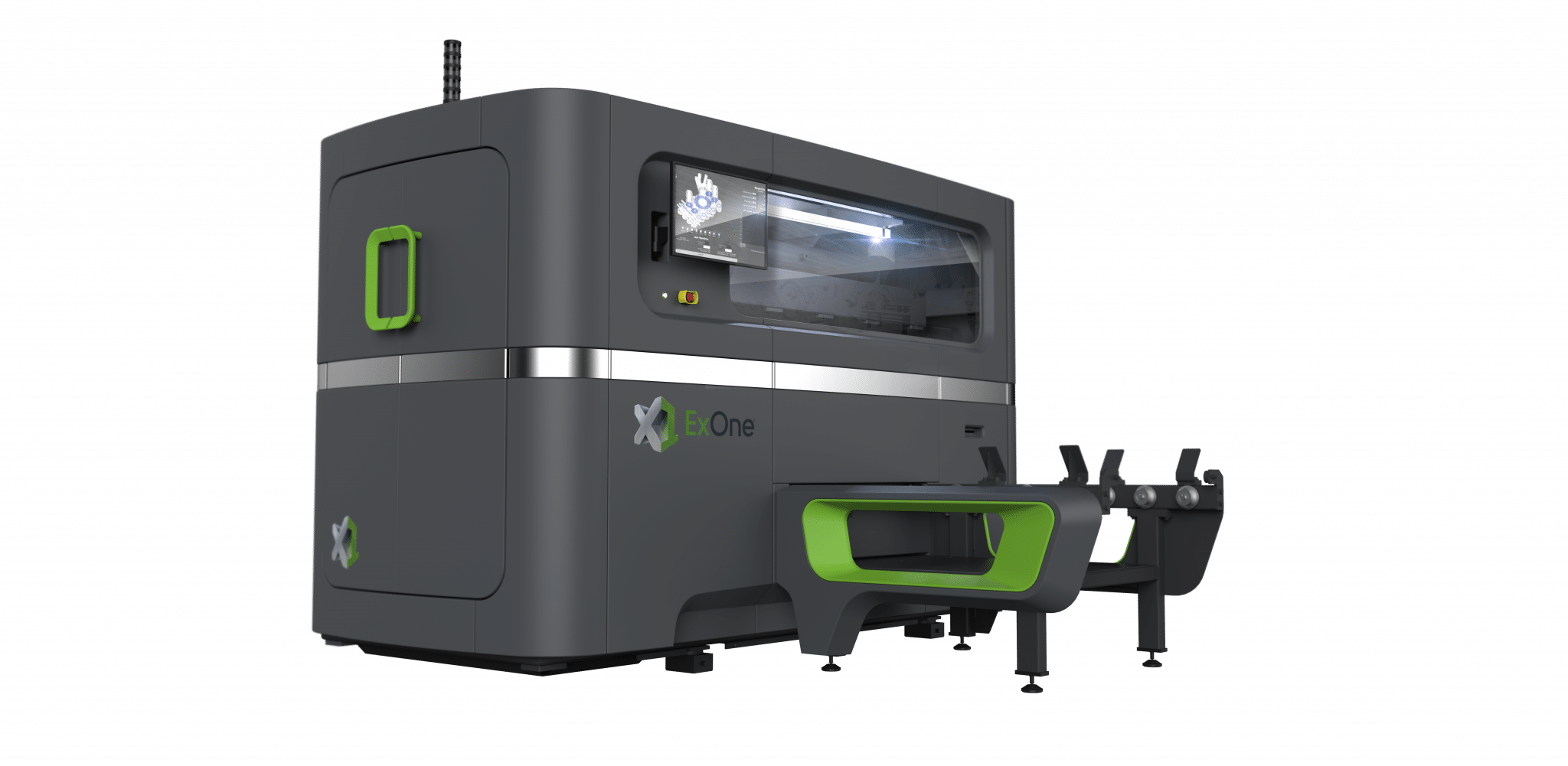

TRUMPF acquires SISMA’s additive manufacturing business AM Industry

It was in the air, and now it’s official. TRUMPF has acquired the joint venture with SISMA in Italy completely which means the German company’s additive business will now focus on the medical and dental businesses as well.