Dutch company Aectual, specialized in the creation of 3D printed architectural and interior design products, has launched a new product series in cooperation with Gramazio Kohler Research at ETH Zürich. The new collection consists of customizable 3D printed acoustic diffusion panels made from 100% circular plant-based materials.

The acoustic panels are suitable for all types of spaces, from commercial venues to residential spaces, and are designed to reduce reverberation and echoes to create a calmer environment. By leveraging its large-scale 3D printing solution, Aectual is able to fully customize the panels so that they can fit into spaces seamlessly. More than that, the company says the panels can be tailored to the customer’s style as well using a dedicated design platform.

Manufacturing on Demand

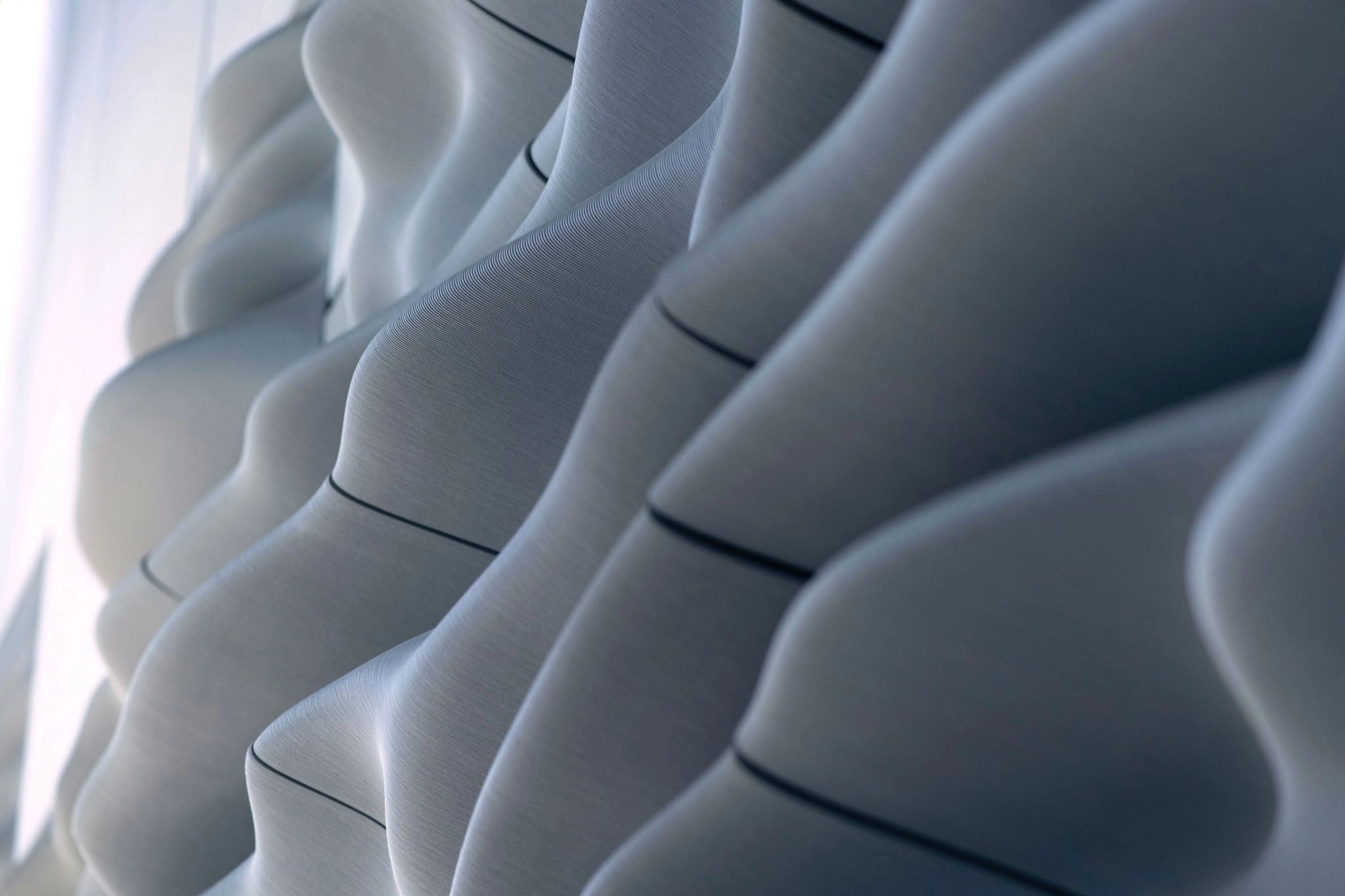

The overall design concept for the acoustic diffusion panels, which evokes waves and ripples found in nature, was conceived by the Gramazio Kohler Research team. The specific structure of the panels, which is custom generated based on the space in question, consists of a parametrically designed surface that disperses sound waves, softening the edges of hard sounds. The rippling design of the panels is reportedly capable of absorbing about 50% of reflected sound waves.

“Acoustics and architecture are directly linked with each other. Although sound is not visible, the geometry of a room and its acoustic characteristics are intrinsically coupled,” explained Prof. Matthias Kohler at Gramazio Kohler Research, ETH Zurich. “This connection between aesthetics and acoustics provided the point of departure for our team to create beautiful acoustic panels that are specifically designed to give rooms a pleasant and soft feeling. We are thrilled to work with Aectual as they bring our designs to life.”

“Aectual’s founding mission is to provide 100% circular, on-demand, smart design solutions that make use of digital design and digital manufacturing,” added Hedwig Heinsman, Aectual Co-Founder and Chief Commercial Officer. “Our collaboration with Gramazio Kohler Research demonstrates Aectual’s ambition to bring together academic research and innovative designs to a wide audience, by offering designers and academia a single platform to publish, manufacture, and directly share and sell their designs.”

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Tess Boissonneault

Leave A Comment