Anycubic is one of our favorite companies. We like their branding and we love the way they have made good quality 3D printing available to an unprecedented number of users around the world. They strive to make high-quality products at an accessible cost. The proof is that they are one of the very first companies to work with DLP technology inventors Texas Instrument to create the most affordable DLP 3D printer ever, the upcoming Anycubic Photon Ultra. But until now we had known Anycubic only for their LED/LCD stereolithography systems and when they asked us to test the new Anycubic Vyper we did not know what to expect.

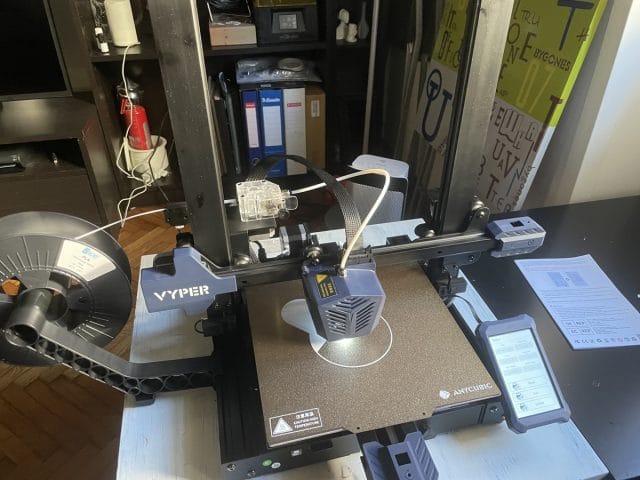

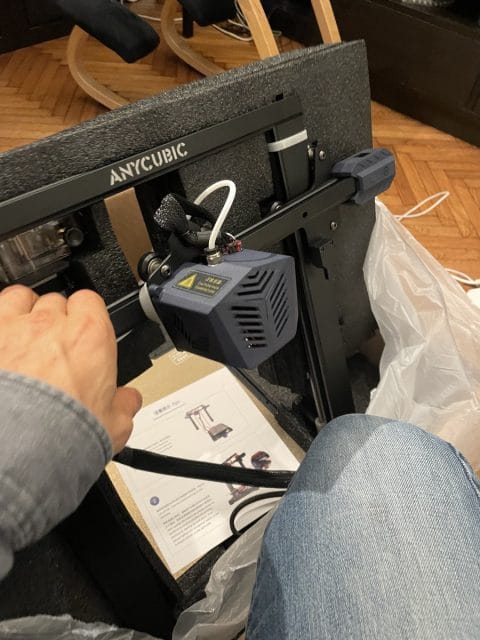

Fortunately, as the video shows, it only took a few short minutes (just seconds in timelapse) to get printing and familiarize ourselves with this new Anycubic filament extrusion system. You may think that, after testing a few different machines, we’d be quite good at it however nothing could be further from the truth. While there are technically savvy people at 3dpbm, and we do have support from friends at local FabLabs and 3D printing services, this writer, in particular, is the epitome of the “mechanically poor” consumer and known to break many 3D printers for trivial reasons.

So if this writer can get printing within a few minutes from unpacking, just about anyone can. Every wire connection is easy to identify and plugin, and it only takes 4 screws to build the frame and 3 more for the display. That’s good for a machine that targets a wide segment of users and hobbyists that just want to print parts without tinkering too much with the hardware. But it’s also proof of the quality level that these sub-$500 3D printers have now achieved. In this price tag, Anycubic provides everything you’ll need to assemble the system and print parts: SD card and adapter, ethernet cable, spatula, replacement extruder tip, sample filament and all the hexagonal keys and tools in a convenient tray that fits right into the machine.

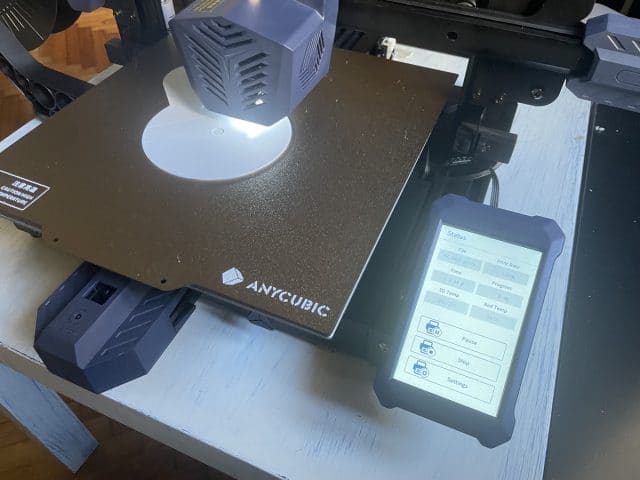

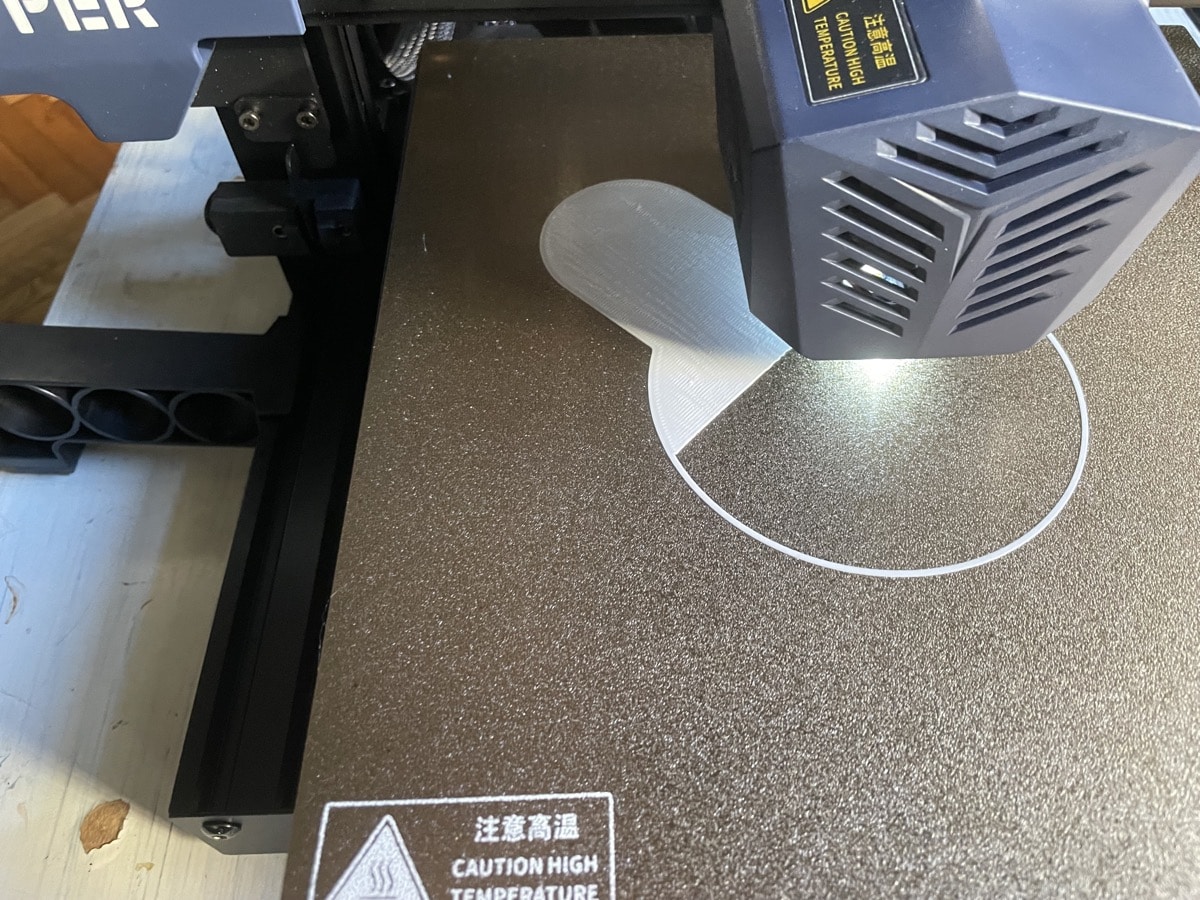

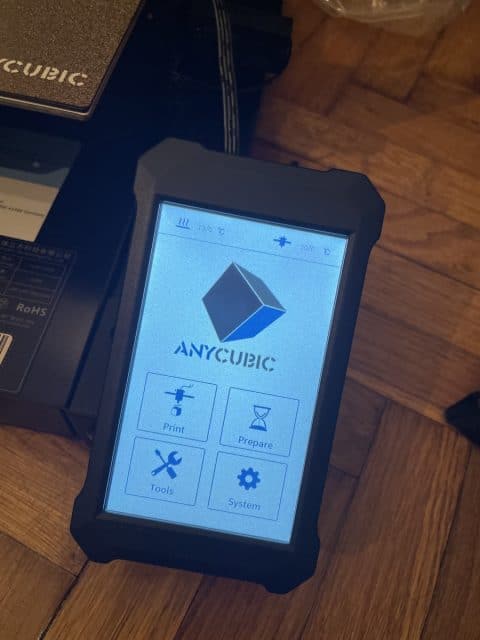

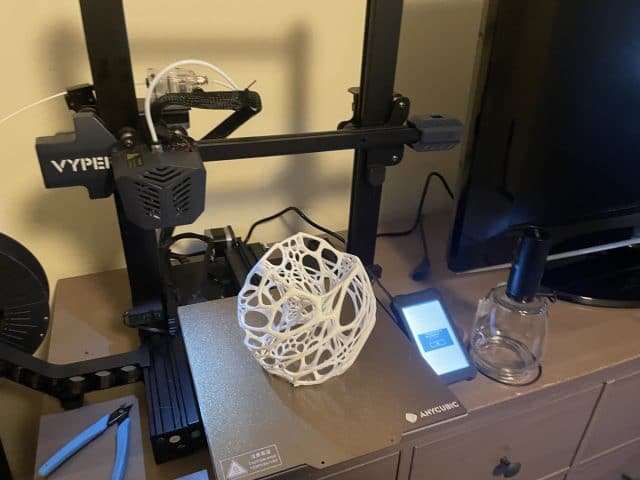

The first and most impressive feature of the Anycubic Vyper is the completely automated leveling function. The first thing you do, after turning the machine and its full-color 4.3″ touch-screen display on, is to press the auto-level button. The Vyper does everything else to get the plate perfectly leveled and the results are immediately obvious in the very first layer of the print. Which is simply perfect. And most users of desktop 3D printers know that getting the first layer just right is a big part of getting the part printed properly.

Manufacturing on Demand

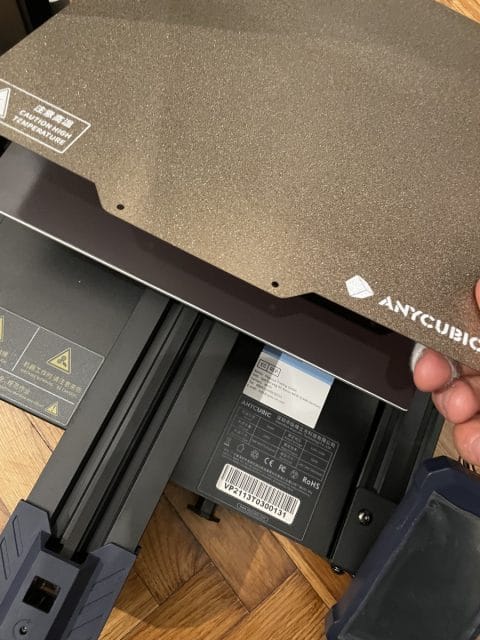

There is also another feature that makes this printer very convenient to use: the magnetic, steel build platform: the tough adhesion platform features a scratch-resistant coating and instantly sticks to the build plate without the need of clips or rubber bands. When the parts are finished, the plate can be removed easily and the parts just come off easily as soon as it cools down, for most filament materials.

The Vyper’s internal hardware is high-quality as well: the machine comes equipped with a new 32-bit motherboard and a high-performance Cortex -M3 architecture main control chip, which enables faster computing speed and a smoother run. This makes it a lot quieter than most comparably priced 3D printers: the integration of the TMC2209 silent driver enables both silent printing and precise voltage output control, which ensures higher accuracy and silent printing.

Other features include elements we’ve now come to expect, even from ultra-affordable desktop 3D printers, such as a fairly large build volume of 245mm(L)×245(W)×260mm(H) and the nozzle running up to 260°C, with the addition of a few more perks. One is the high-precision double screw, running synchronously for stabler operation and reduced zeroing errors. Another is the double-gear extrusion system which reduces the chances of filament tangle and supports flexible filaments, combining a strong extrusion force and path optimization. Finally, the dual cooling fans’ two-way heat dissipation system cools down models rapidly, making the optimal printing speed as fast as 100mm/s.

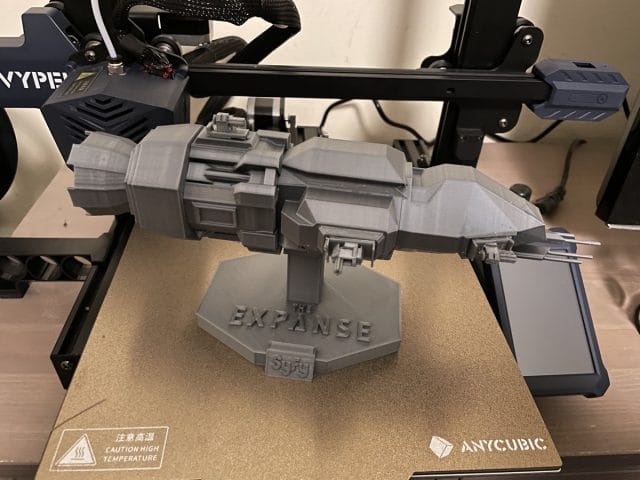

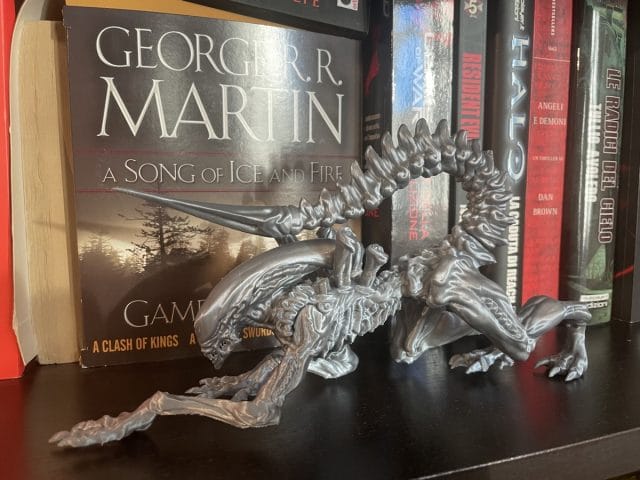

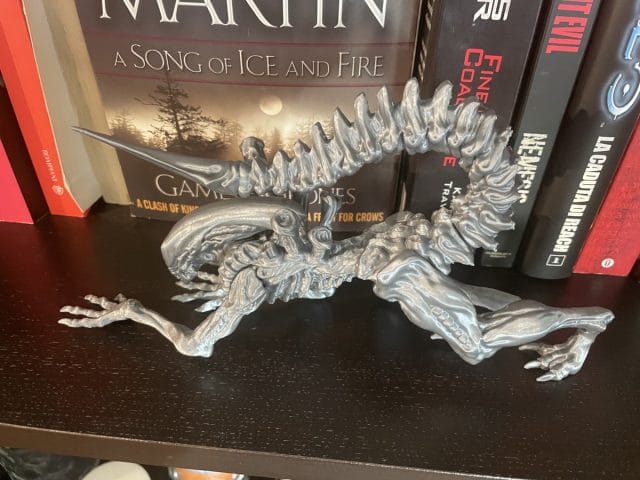

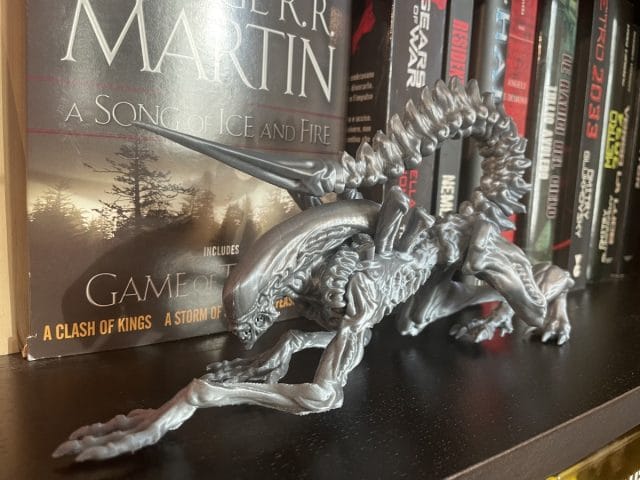

We have been printing Christmas gifts for friends and children with optimal results. Some of the more challenging prints, such as the beautiful generatively designed Cellular Lamp from Nervous Systems (on Thingiverse), which has some complex overhangs. We also tested out the foldable articulated Star Wars ATAT from Fab365, which requires tight tolerances, also came out ok. These prints are always more challenging than their creator makes them look. We gave it a go on a simplified, modular Rocinante design from the Expanse (also on Thingiverse), to celebrate the final season of best sci-fi series of all time. We also made dozens of the definitive “3D print of the moment”, the Articulated Dragon by McGybeer from Cults3D, to give out to friends and family over the holiday period. A fantastic design, which came out perfectly every time, and helped us clearly explain the potential of 3D printing to those completely unfamiliar with it.

Overall we can definitely recommend this 3D printer to both consumers and hobbyists. We have had it for over a month, using it regularly, and did not run into any issue that was due to a mechanical flaw. We did clog up the extruder, using an old filament that had deteriorated but we never ran into any issue using standard PLA filament.

You might also like:

Desktop Metal rebrands EnvisionTEC as ETEC to move into new era:

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment