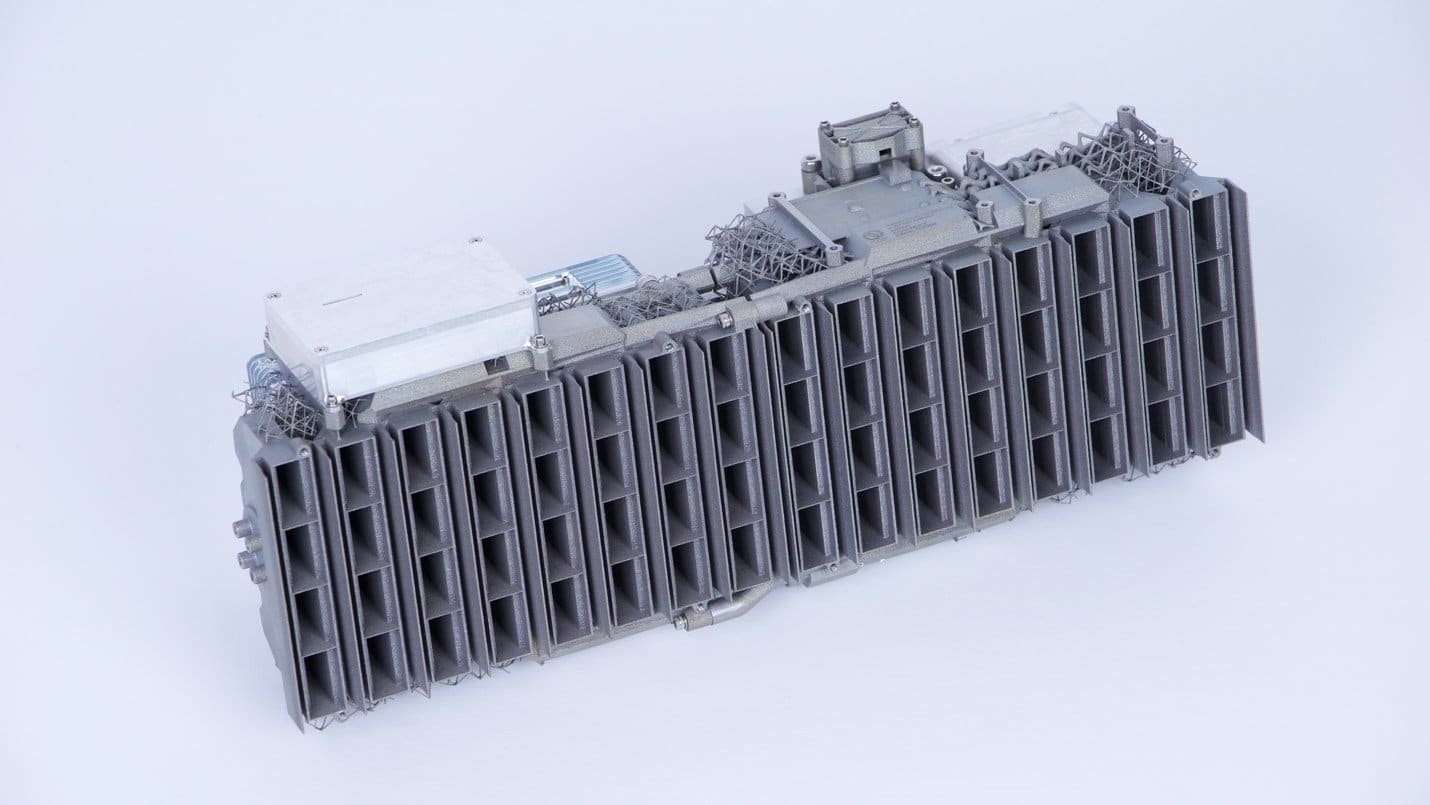

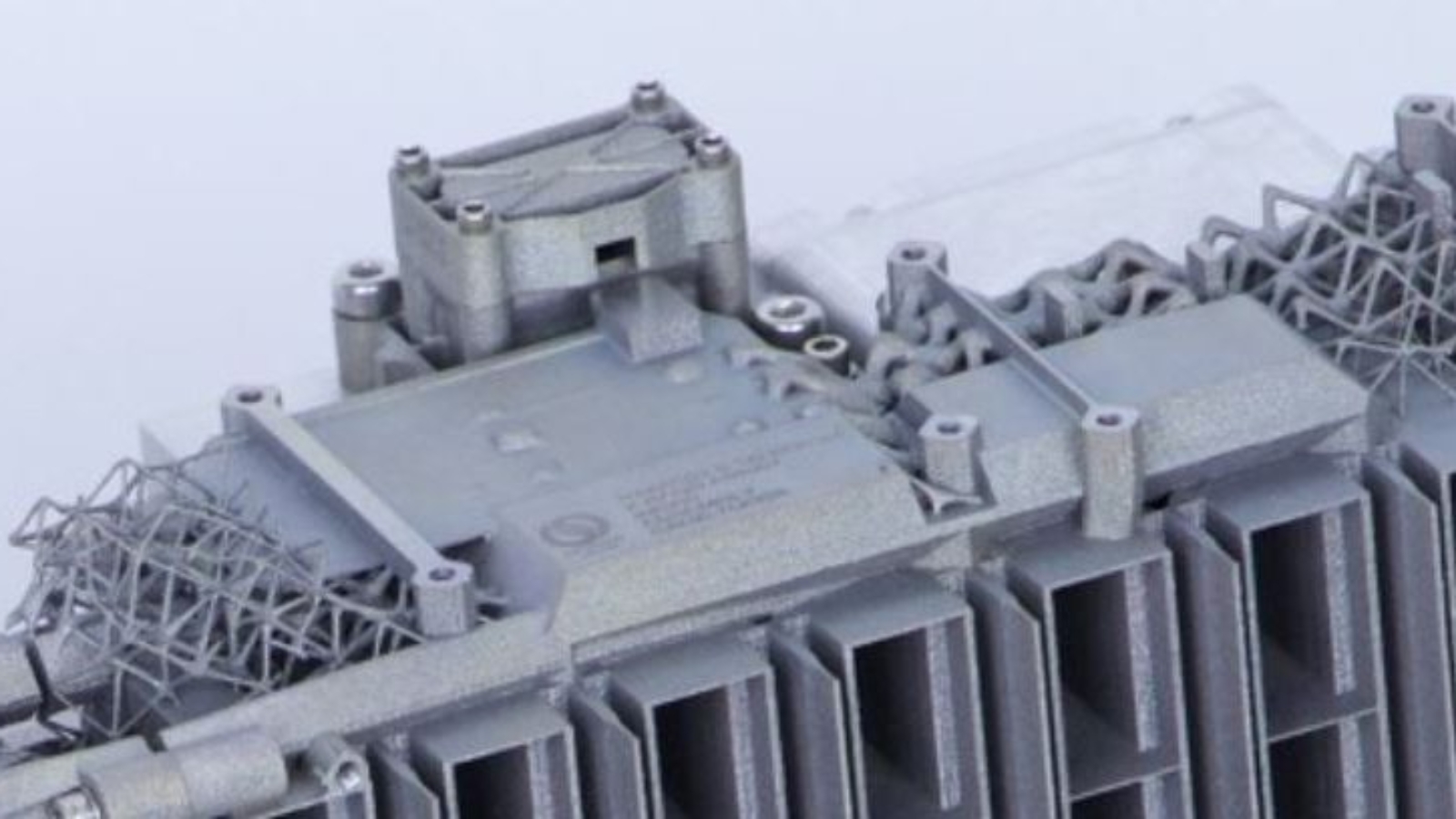

After entering the AM market both directly (with internally developed solutions, including metrology) and through major acquisitions (aerospace AM service provider Morf3D and laser PBF hardware manufacturer SLM Solutions) Nikon Corporation has now acquired its first AM application developer, Optisys, Inc. The Utah-based company is a global leader in the design and manufacture of metal printed antennas for commercial and government applications where high performance, size, and weight are critical. The Optisys IP portfolio includes many proprietary antenna designs as well as revolutionary RF solution design improvements that support mass customization capabilities.

The demand for communications and radar antenna systems produced using metal additive manufacturing continues to grow as users recognize the benefits in size, weight, and power reduction (SWaP). Designing for metal 3D printing creates highly specialized components that provide enhanced performance. It also enables rapid modifications and simplifies the integration of new features, while providing a net reduction in total parts by enabling multiple antenna components to be designed into a single piece. Optisys utilizes integrated design, manufacturing, and test processes to deliver cost-effective, tailored solutions in shorter development time, while ensuring critical product performance for the aerospace industry.

The demand for communications and radar antenna systems produced using metal additive manufacturing continues to grow as users recognize the benefits in size, weight, and power reduction (SWaP). Designing for metal 3D printing creates highly specialized components that provide enhanced performance. It also enables rapid modifications and simplifies the integration of new features, while providing a net reduction in total parts by enabling multiple antenna components to be designed into a single piece. Optisys utilizes integrated design, manufacturing, and test processes to deliver cost-effective, tailored solutions in shorter development time, while ensuring critical product performance for the aerospace industry.

Manufacturing on Demand

Nikon has long been recognized for manufacturing some of the most precise equipment ever made. Its products and technology are used in applications ranging from medical systems to satellites and automotive, as well as semiconductor processing and mass production of panels for TVs and a host of smart devices. By leveraging synergies resulting from global alliances and strategic investments with companies at the forefront of their industries, the Nikon Next Generation Project Division strives to accelerate growth in additive manufacturing and other pivotal technologies.

This investment will enable Nikon and Optisys to boost the utilization of metal additive manufacturing for applications including high-performance antennas and other RF solution products. “This investment in Optisys is another central element of our Next Generation Project program to propel industrialization of digital manufacturing, “Yuichi Shibazaki, Nikon Corporate Vice President and General Manager of the Next Generation Project Division said. “Optisys’ industry leadership and precision design and manufacturing capabilities are well-aligned with Nikon core technologies and our vision for the future. We look forward to partnering with their team to expand the additive manufacturing horizon.”

Janos Opra, Chief Executive Officer of Optisys, said, “Nikon’s investment and expertise in additive manufacturing and advanced manufacturing techniques gives Optisys access to an ecosystem where we will be able to produce high-performance printed antennas in commercial volumes. This will enable Optisys to bring additive manufactured antennas into the mainstream for the most demanding market segments in both commercial and government applications.”

You might also like:

Makerbot and Ultimaker successfully complete merger: Combining both companies’ products platform under one roof, UltiMaker will continue to offer a wide range of solutions to customers – with well-established brands such as the MakerBot METHOD, MakerBot SKETCH, MakerBot Replicator 3D printers, and MakerBot CloudPrint, as well as the Ultimaker 2+ Connect, Ultimaker S3, Ultimaker S5, and Ultimaker S5 Pro Bundle. In addition to this, the open communities – Ultimaker Cura and MakerBot Thingiverse – will continue to be managed by the new company.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Davide Sher

Leave A Comment