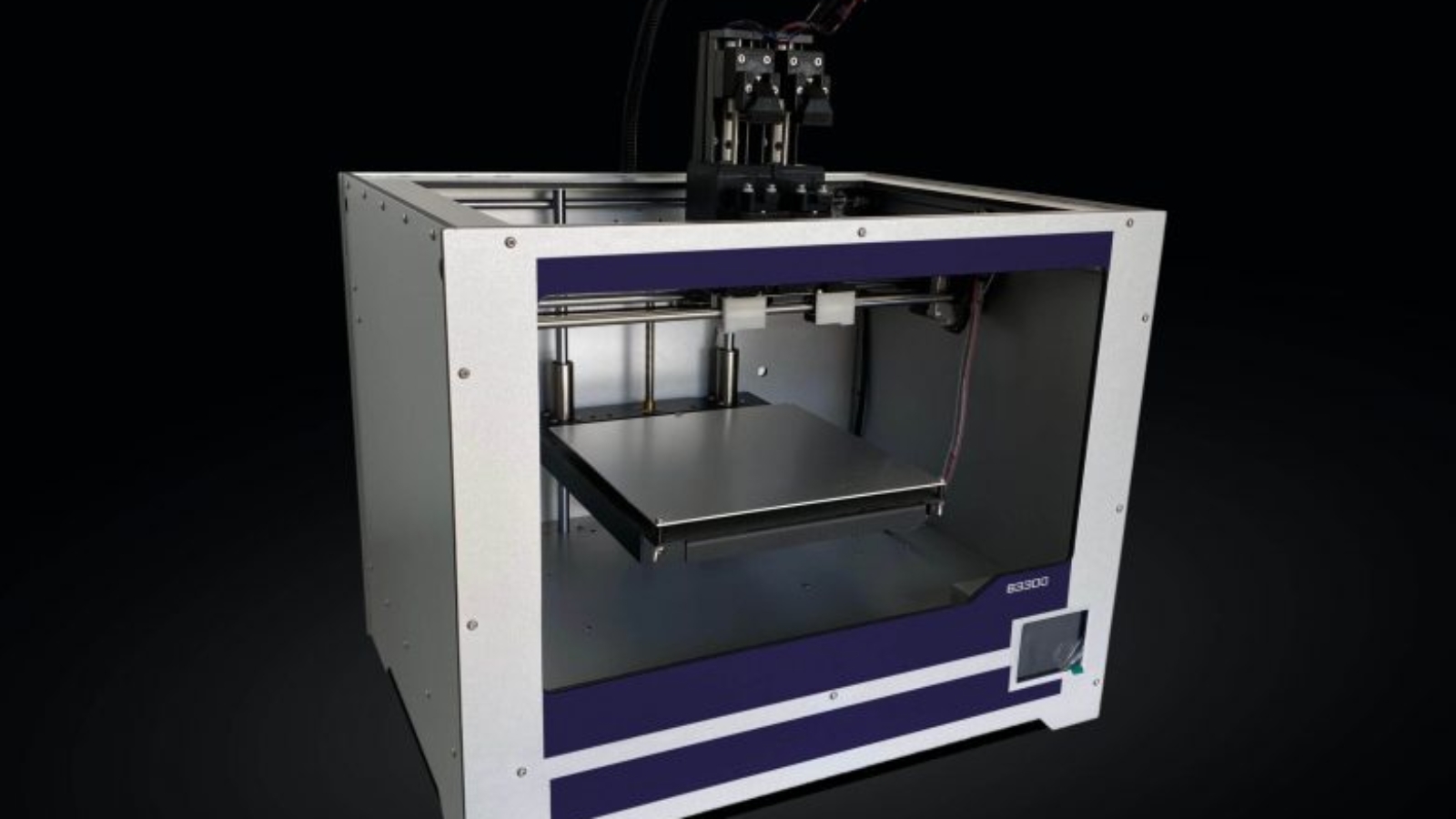

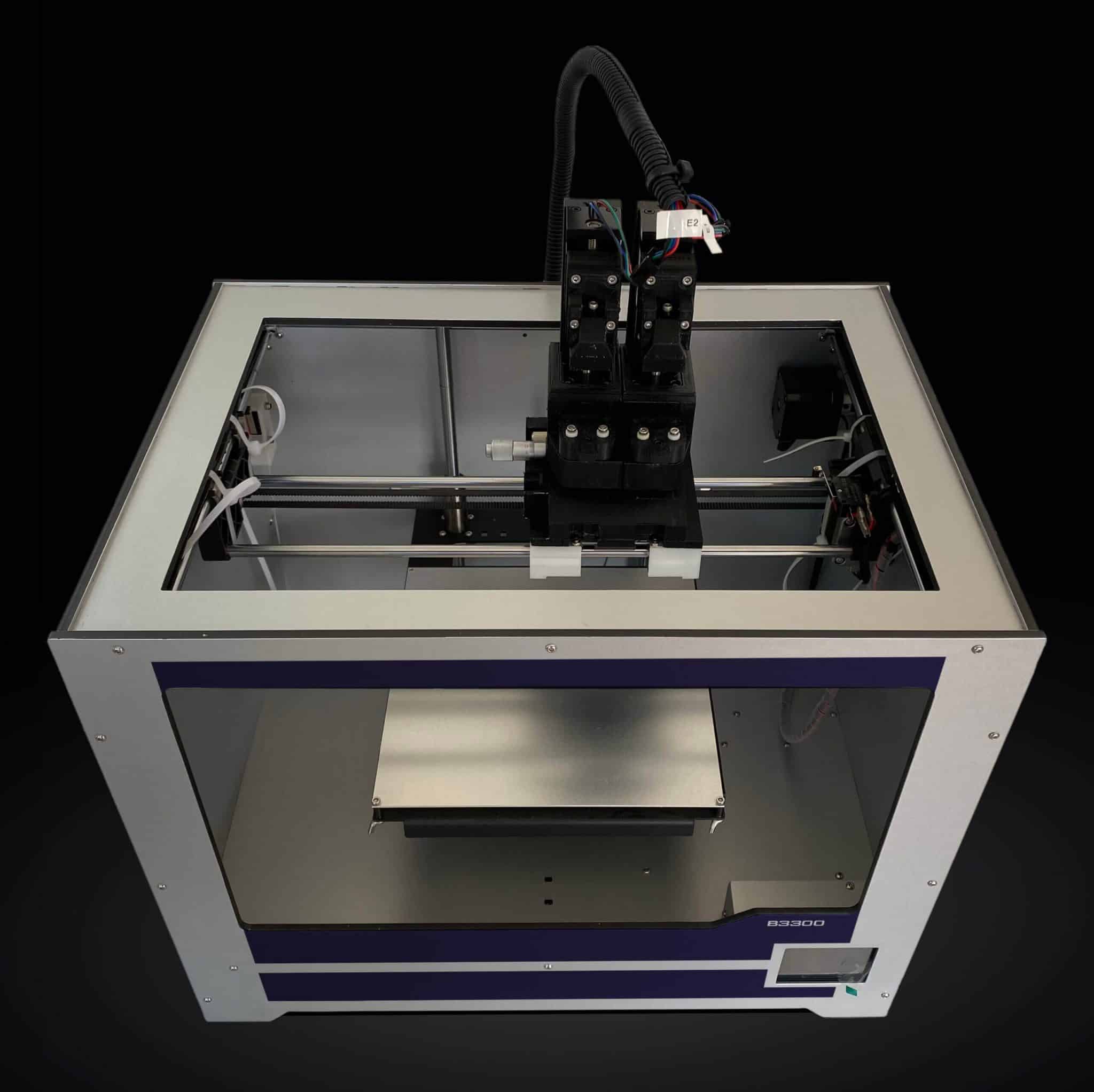

nano3Dprint, a next-generation additive manufacturing solutions provider, has launched its B3300 dual-dispensing 3D printer. The B3300 produces objects such as medical devices, wearables, batteries, solar, and other functional electronics with embedded circuitry.

The printer’s unique, proprietary dual material dispensing system can print two different materials together to build combined material prints. The B3300 expands users’ range of printing materials – from gold and silver to UV curable polymers and silicone.

Manufacturing on Demand

“The B3300 3D printer is a great solution for a wide range of applications. It can print wearables with embedded conductors, cell phone parts with internal antennas and electronic devices with internal sensors,” said Gretta Perlmutter, Product Success Manager at nano3Dprint. “It allows for incorporating sensors, strain gauges, heaters, complex antenna geometries and optical components in a 3D print and provides manufacturing solutions for the medical, agriculture and solar industries, and general consumer electronics.”

“This is a revolutionary development within the electronics 3D printing industry; new combinations of materials difficult to print together, like silicone and gold or dielectrics with semiconductors, can now easily be printed in combination with the B3300,” added Gretta Perlmutter.

The printer’s video inspection system allows users to monitor their progress in real-time via a computer to ensure an error-free high-resolution design print with accurate layer height, surface finishing, tolerance, and roundness. The B3300 3D electronics printer is compatible with SD cards and flash drives for direct printing and is small enough to fit on a desktop. It is compatible with most CAD or Slicer software and retails for $6,000.

You might also like:

iFactory3D introduces One Pro 3D belt printer: The use of a conveyor belt instead of a rigid print bed bridges the procedural gaps of additive manufacturing. As a result, the One Pro prints long objects in virtually unlimited lengths and enables simultaneous, automated batch production with minimal human-machine interaction. The 45° printing angle means less material is required and complex geometries (including hollow shapes) can be printed without support structures – enabling the printing of bionic features, for example, that can be reinforced with resin, foam, and fibers, and have an optimized topology.

* This article is reprinted from 3D Printing Media Network. If you are involved in infringement, please contact us to delete it.

Author: Edward Wakefield

Leave A Comment