Industrial 3D printer manufacturer Stratasys has introduced a new software module, the Digital Anatomy Creator, for its Digital Anatomy 3D printers in order to enhance the production of 3D printed anatomic models.

Alongside the new software module, the company has partnered with third-party software vendors Synopsys’ Simpleware ScanIP Medical and Materialise’ Mimics inPrint to certify its Digital Anatomy and J5 MediJet printers to be included in FDA 510(k) cleared medical modeling workflows.

Elsewhere, Stratasys’ recently launched H350 3D printer has also been leveraged by German design firm DQBD to produce fully personalized cycling saddles that offer increased comfort and performance efficiency over those produced via traditional methods, while slashing lead times and production costs.

Advancing personalized healthcare

Stratasys’ Digital Anatomy 3D printer was originally launched in 2016 for the production of anatomical models for the medical sector. Since then, the printer has been validated by global color authority Pantone and received medical upgrades, including the capability to create models that mimic human bone.

The company launched its J5 MediJet 3D printer in June this year, designed specifically for medical applications such as patient-specific anatomical models, surgical guides, and medical tooling. The full-color system leverages Stratasys’ PolyJet technology and is compatible with a wide array of sterilizable and biocompatible 3D printing resins.

The Digital Anatomy Creator module

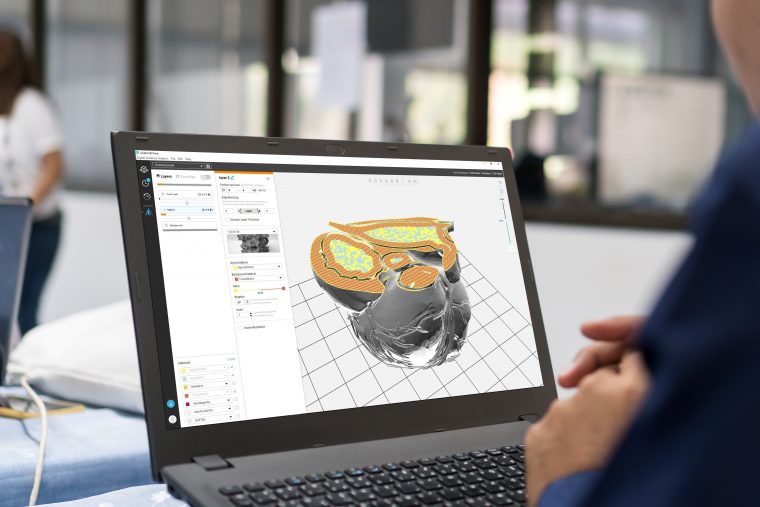

Now, Stratasys is advancing the capability of its medical machines with a new software module, the Digital Anatomy Creator, which allows users to produce patient-specific anatomic models that are a direct replica of a patient’s anatomy.

Through the module, users can easily manipulate material formations and customize the internal structures of their prints thanks to additional options and controls. This capability allows users to calibrate their printers’ materials to meet the specific requirements of each anatomic model, in order to customize and produce ultra-realistic models that behave and respond like the real thing.

The Digital Anatomy Creator also enables users to create, replicate, and share designs across a community dedicated to patient-specific anatomies for a wide range of applications, ranging from diagnosis to patient education.

“The Digital Anatomy Creator is the missing link between the patient, the printer and the final printed 3D anatomic model,” said Seth Friedman, Manager of Innovation, Imaging and Simulation Modeling for Seattle Children’s Hospital. “This new software has allowed us to personalize our anatomic models to a mind-blowing level – we can now provide a level of care that is truly personalized to each of our patients, which is really important when working with children and their caregivers.”

Alongside the introduction of the new module, Stratasys has certified its Digital Anatomy and J5 MediJet 3D printers to be included in FDA 510(k) cleared medical modeling workflows, through partnerships with third-party software vendors. Synopsys’ Simpleware ScanIP Medical and Materialise’s Mimics inPrint software will enable Stratasys’ customers to access workflows for diagnostic anatomic modeling and point-of-care 3D printing.

“We continue our journey towards accessible, accurate, and realistic 3D medical modeling by deepening our structural pathology flexibility with the introduction of the Digital Anatomy Creator module and by validating our digital workflow with third-party segmentation software with FDA 510(k) clearance,” said Osnat Philipp, Vice President, Healthcare, for Stratasys.

Manufacturing on Demand

“Our solutions allow providers to deliver best-in-class healthcare that leads to better outcomes and establishes a new level of care.”

Optimizing cycling saddle production

Moving away from the medical sector now, and Stratasys has revealed how its recently launched H350 3D printer has been leveraged to produce customized cycling saddles at scale.

Unveiled in April, the H350 is powered by Stratasys’ Selective Absorption Fusion (SAF) technology, based on a high-speed sintering process originally developed by Xaar, which Stratasys acquired in October.

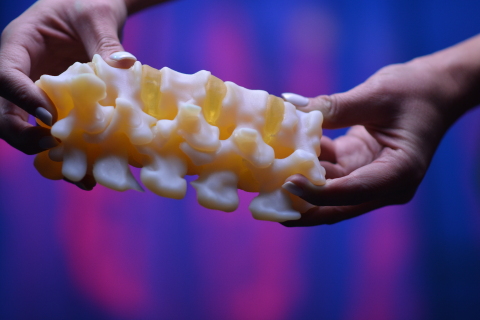

The H350 has been deployed by DQBD to produce fully personalized bicycle saddles that reportedly deliver a higher level of comfort and performance efficiency compared to regular saddles. The design firm is 3D printing a number of the saddle’s load-bearing parts at scale using the machine, and says Stratasys’ SAF technology has so far enabled it to save up to £22,000 while slashing lead times from six months to just 10 days compared to injection molding processes.

“We have always planned for additive manufacturing to play a pivotal role in the creation of SAM – our cycling saddle,” said Sebastian Hess, CEO at DQBD. “In fact, we designed the saddle with additive manufacturing in mind. As well as delivering consistently accurate, production-grade parts at volume quickly and affordably, the technology offers a unique opportunity to personalize products in a way that cannot be replicated with traditional methods.”

The SAM saddle is made up of a semi-rigid, personalized PA11 3D printed spine and a 3D thermoformed seat pad. DQBD uses software mapping of pressure points and weight distribution to match the geometry of the saddle with the rider’s body and riding position, while the composition of rigid and flexible zones within the saddle’s 3D printed spine offers support and adaptation where it is needed.

According to DQBD, the combination of rigid and flexible zones will offer a higher level of comfort to the rider, while reducing fatigue. The entire saddle assembly is also glue-less, meaning the components can be easily separated and reintroduced into production at the end of the saddle’s lifetime.

“We are definitely seeing a trend in businesses’ readiness for volume production of end-use parts,” said Yann Rageul, Head of Manufacturing Business Unit EMEA & Asia at Stratasys. “DQBD is showcasing how the H350 and its SAF technology can not only optimize the entire production process with valuable time and cost savings, but also shows the deployment of additive manufacturing for truly unique and advanced designs – ready for production at scale.

“We are proud to see that the SAM saddle design DQBD created shows the advancements of additive manufacturing within the product development cycle – as the product concept was designed around additive manufacturing from the start.”

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment