Researchers at the University of Stuttgart and Robert Bosch Hospital are developing a novel 3D printed tissue platform that could replace animal testing in clinical trials.

As part of a €3.8 million project sanctioned by the German state of Baden-Württemberg, the scientists are attempting to fabricate an ex-vivo tissue model for testing cancer drug efficacy. Using a 3D bioprinter and simulation data, the joint team believes that it’s now possible to create skin-like microfluidic structures that, if anything, yield more realistic tumor progression predictions than before.

“If we are able to filter out the best drug candidates in ex-vivo culture systems, we can significantly reduce the number of experimental animals used in final preclinical tests,” said Professor Roland Kontermann of the University of Stuttgart. “To replace animal testing altogether, de-novo and in-silico models will offer great potential in the future.”

Ending animal experimentation

While there’s no doubting the importance of research into deadly diseases like cancer, a huge amount of testing conducted on animals each year is considerably less crucial. In Germany alone, around three million critters ranging from birds to cows are experimented on every year, but only 13% of these tests relate to treating diseases.

In fact, 47% of all German animal testing is necessitated by basic research, while another 18% is used for educational, training or breeding purposes. Given the cruelty and reliability arguments levelled against the practise, a considerable amount of research is already being conducted into synthetic alternatives, but none have been fruitful so far.

Organ-on-a-chip devices have shown particular promise in this area, with Harvard University scientists 3D printing a ‘heart-on-a-chip,’ and a Universidad Autónoma de Madrid team creating a blood vessel replication device. However, despite these advances, there remains a need for the development of a more substantial organic platform, that better recreates the responses of living tissues.

The Baden-Württemberg project

Essentially, the €3.8 million South-West German program has established a state-wide network of universities, with each researching different methods of improving animal welfare. In the ‘3R-US’ part of the project, the Stuttgart scientists are attempting to develop an ex-vivo cancer testing model, but initial progress has been tricky thus far.

While it’s proved possible to conduct trials on cancer cells in petri dishes, the active ingredient is effectively fed directly to them, which isn’t an accurate reflection of the body’s distribution process. Even when mice are used as in-vitro substitutes, their immune systems are different, necessitating the creation of a novel solution.

Manufacturing on Demand

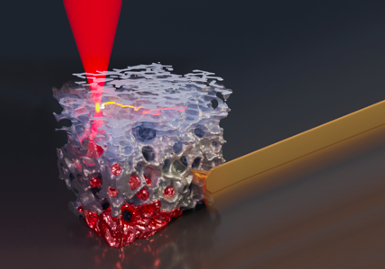

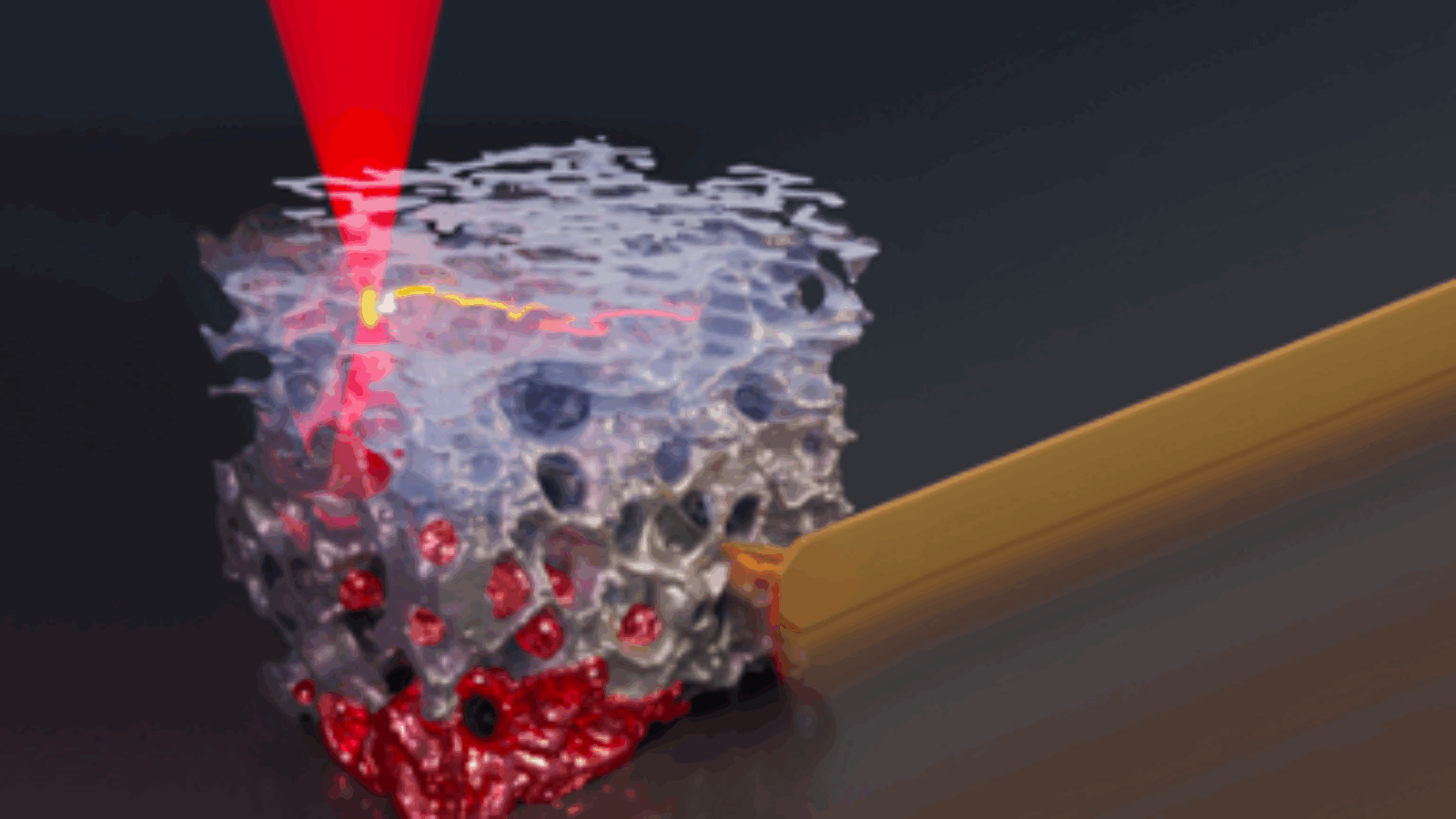

To overcome these issues, the 3R-US team are adopting a three-pronged approach to developing live 3D models: ex-vivo, de-novo and in-silico. Utilizing a 3D bioprinter, the scientists now intend to fabricate bulkier customized and nutrient-loaded cell structures, that are capable of yielding more conclusive test results.

According to the University of Stuttgart’s Michael Heymann, these printed tissues feature tiny “lego-like bricks,” that can be assembled into realistic in-vivo tumors. Eventually, by experimenting on these cell-based structures, the team aims to generate enough data to construct an in-silico model, that more accurately simulates drug distribution.

For now though, the scientists are only at the start of a five-year project, and they intend to form a close knowledge-sharing partnership going forwards, that creates a synergy between biotechnological and medical technology expertise.

3D bioprinting soft tissue models

Although realistically recreating the behaviors of organic soft tissues remains challenging, a number of developments have been reported over the last year.

Researchers from Tsinghua University have managed to 3D bioprint brain-like tissue that’s able to respond to external stimuli. While the cells ultimately proved capable of forming neural networks, they were essentially removed from a lab rat’s brain, somewhat working against what the Stuttgart team are trying to achieve.

Several recent R&D projects have also yielded novel bioprinting materials that could prove essential to the technology’s development. Scientists from Texas A&M University, for instance, have developed a ‘NICE’ 3D printing bio-ink, that exhibits a higher level of stability than prior formulations.

Similarly, engineers from Rutgers University have created a novel bio-ink made of living cells, that can be used to 3D print scaffolds for human tissue growth. In future, the Rutgers team aims to combine its biomaterial with others, in order to develop skin-like structures with customized application-specific properties.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Paul Hanaphy

Leave A Comment