Additive manufacturing and 3D scanning have been increasingly integrated within the healthcare sector. 3D Systems, in particular, has contributed significantly to the advancement of surgical procedures with this technology.

Last year, the company, based in Rock Hill, South Carolina, began offering its Virtual Surgical Planning (VSP) technology as well as its range of 3D anatomical models through medical technology firm Stryker. As a result, 3D Systems has provided VSP or anatomical services in more than 100,000 cases, including facial reconstruction surgery and full facial transplants.

But in addition to this AR/VR is also used by 3D Systems to help medical professionals improve surgical outcomes.

Ran Bronstein has worked in the field of medical simulation for over twenty years and co-founded Simbionix, a company providing 3D virtual reality surgical simulation, which was acquired by 3D Systems in 2014. With his experience, Bronstein aims to leverage anatomical modeling and simulation technologies, to train medical professionals for better patient-specific based healthcare.

In a recent interview for Bronstein, 3D Systems Vice President, and Chief Research and Operations Officer, commented, “Physicians can practice on animals or on cadavers, and sometimes need to practice on actual patients. We want them to be very well trained, and computerized simulation is something that aims to replace these old methods.”

A simulation for surgical success

“Pilots have been using simulators for many years. But there are more physicians than pilots,” stated Bronstein. “Sometimes physicians make a greater number of mistakes than pilots. To prevent these mistakes and improve patient safety and procedure outcome, we decided to develop a medical simulator based on the same concept.”

Manufacturing on Demand

Among its simulation solutions is the RobotiX Mentor training module. This allows trainees to practice surgeries in a virtual environment using step-by-step guidance, performance metrics, anatomy recognition, and a video-based curriculum.

“The operating room is becoming more and more complicated, with more modules: virtual reality, X-Ray, ultrasound, MRI, CT and robotics. It is becoming an increasingly technological and complicated environment. Without a simulator, there will be no ability to carry out surgery.”

3D printing helps future physicians

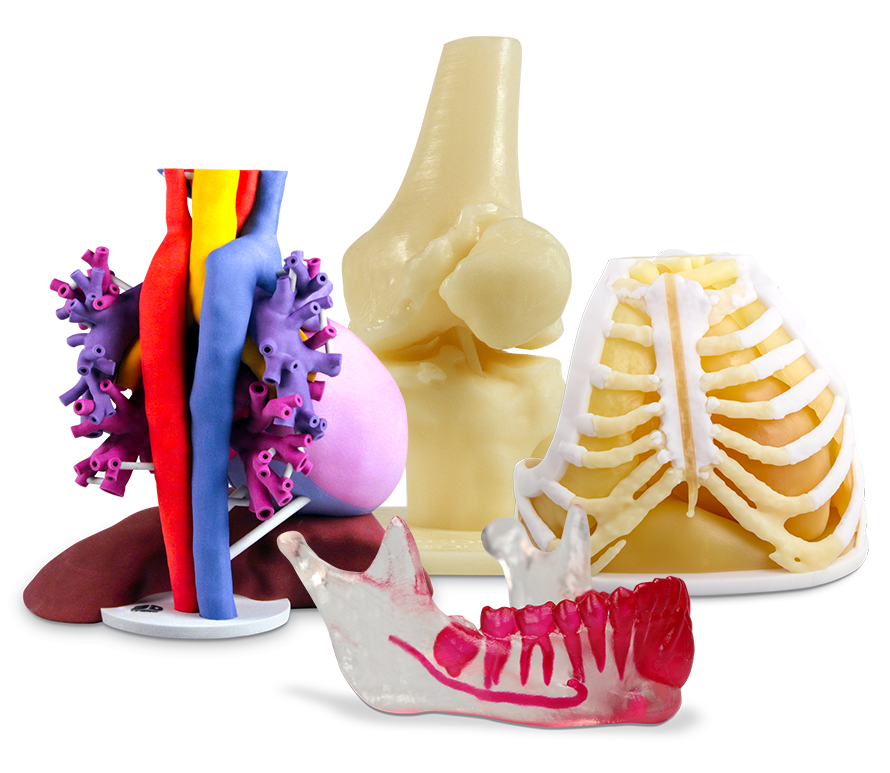

In addition to virtual reality, 3D Systems has also added to its medical portfolio through its recent partnership with non-profit organization OpHeart and its Heart-in-Hand Pledge. More specifically, the company is using its D2P (DICOM to Print) software and ProJet CJP 660Pro ColorJet 3D printers and VisiJet materials to produce customized 3D printed heart models for doctors tending to young patients with Coronary heart disease (CHD).

Prior to this, 3D Systems supported the landmark surgical case of the conjoined McDonald Twins and manufactured over 600,000 3D printed medical devices. The company also recently launched an On Demand Anatomical Modeling Service. This service makes custom 3D printed models to be used in surgical planning and patient education.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Tia Vialva

Leave A Comment