The global footwear industry generated revenues of about $260 billion in 2018 and is expected to grow at around 4% CAGR for the next ten years, totaling around $400 billion by 2029. The segment is mature and growing steadily as hundreds of millions of people around the world—especially in emerging economies—are now able to afford quality footwear.

Within this scenario, AM is expected to play an increasingly important role on several fronts. These include increased adoption in segments where the benefits of AM are consolidated, such as prototyping and indirect manufacturing (i.e. 3D printing of molds and cast patterns for mold production), as well as increased automation for mass production of shoes and other footwear products.

What 3D printing technologies are used for footwear manufacturing?

The most common group of 3D printing technologies used in footwear production today is vat photopolymerization. This group encompasses resin-based technologies like Stereolithography and Digital Light Processing and Carbon’s Digital Light Synthesis (DLS).

These technologies are based on a similar process, whereby a light source (a laser, a projector or light-emitting diodes) is applied to a liquid resin layer by layer, causing it to solidify.

High accuracy, fast printing speeds, and compatibilities with flexible and springy materials, like TPU, silicone and elastic polyurethane, typical for sports shoes, have made resin-based 3D printing technologies a viable production solution.

In addition to resin-based technologies, shoemakers are also adopting powder-based technologies, like Selective Laser Sintering (SLS) and HP’s Multi Jet Fusion (MJF).

These are also optimized to work with elastomeric materials and offer a fast printing speed. However, unlike resin-based technologies typically used for midsoles, SLS and MJF are more commonly used in the production of insoles.

As we will see in the article and chart below, each of these leading footwear AM companies is targeting different footwear final parts and products, relying on different technologies and materials. However, there are some common trends that are based on the overall macro trend of advanced manufacturing: mass customization and digital mass production. Let’s kick it into gear.

Adidas

Application(s): Lattice Mass Produced Midsoles

Technology: DLS (Digital Light Synthesis)

Technology provider: Carbon

Material: Polyurethane

Digital Data: Generative design

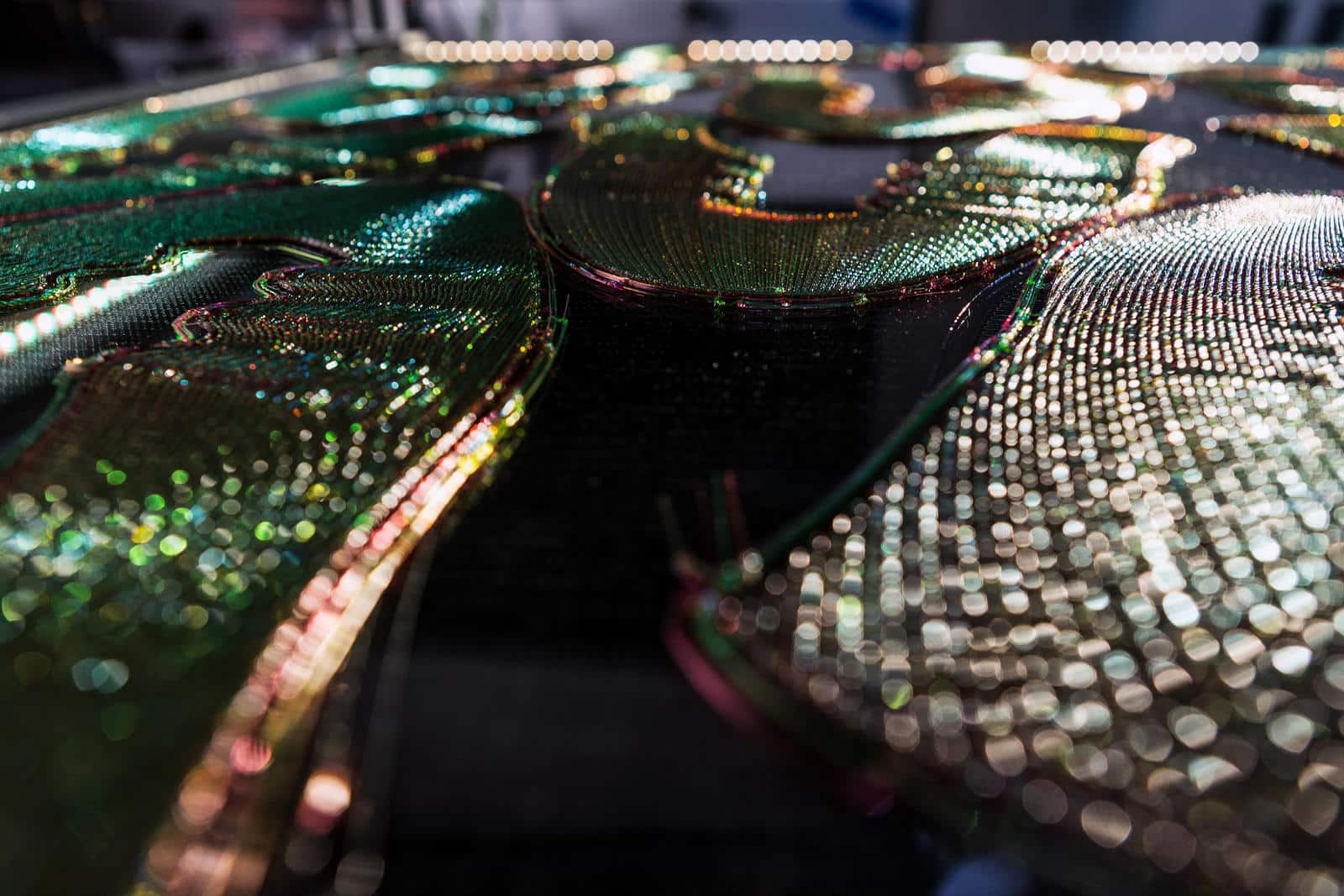

Although it was the latest major footwear company to make a public move into 3D printing of final parts, adidas is the brand that has made the most significant steps toward implementing additive manufacturing in footwear mass production. The company has already produced over 100,000 pairs of shoes with plastic midsoles made via a new 3D technology using Carbon’s Digital Light Synthesis technology (a type of layerless photopolymerization). Now the company has confirmed it is ramping up that production to millions of units in the coming years. Adidas already has access to enough printers from Carbon to make one million pairs of 3D printed sneakers. The process uses a special type of durable and flexible liquid resin which is a combination of thermoset polyurethane and a photopolymerization agent.

- The Adidas Y3 Runner 4D II

The Futurecraft 4D project, Adidas’ first venture into 3D printing, features 3D printed, generatively designed midsoles. The first pairs to be produced cost upwards of $300 (and were quickly sold out). The price has been dropping, not for lack of demand but for scale economics coming into play, lowering the price of materials and hardware accessibility. Since then several new models have arrived on the market including the AlphaEdge and Y-3 Runner, proving that the technology has got legs.

Nike

Application(s): Mass customized uppers, custom football cleats

Technology: SDM (Solid Deposit Modeling), SLS

Technology provider: EOS, Prodways for SLS, SDM developed internally

Material: TPU/nylon

Digital Data: Biometric data, custom designs

Nike was among the first companies to make intensive use of 3D printing in high-performance product development, using the technology for quick iterations of functional parts. The highest profile projects run by Nike is the Nike Vapor Laser Talon, the first 3D printed football cleat specifically designed to provide optimal traction on football turf and to help athletes maintain their “drive stance” longer. While this project did not make it into full production, it was followed by the Nike Vapor High Agility cleat, developed within the company’s “Shuttle” program. 3D printing allowed to test, iterate and create shapes not possible with traditional manufacturing processes, which helped push the limits of innovation faster. In both cases, a Selective Laser Sintering (SLS) process was used along with a proprietary material selection. Nike has also reportedly been working with Prodways on developing a line of 3D printed midsoles using the company’s SLS technology and TPU materials.

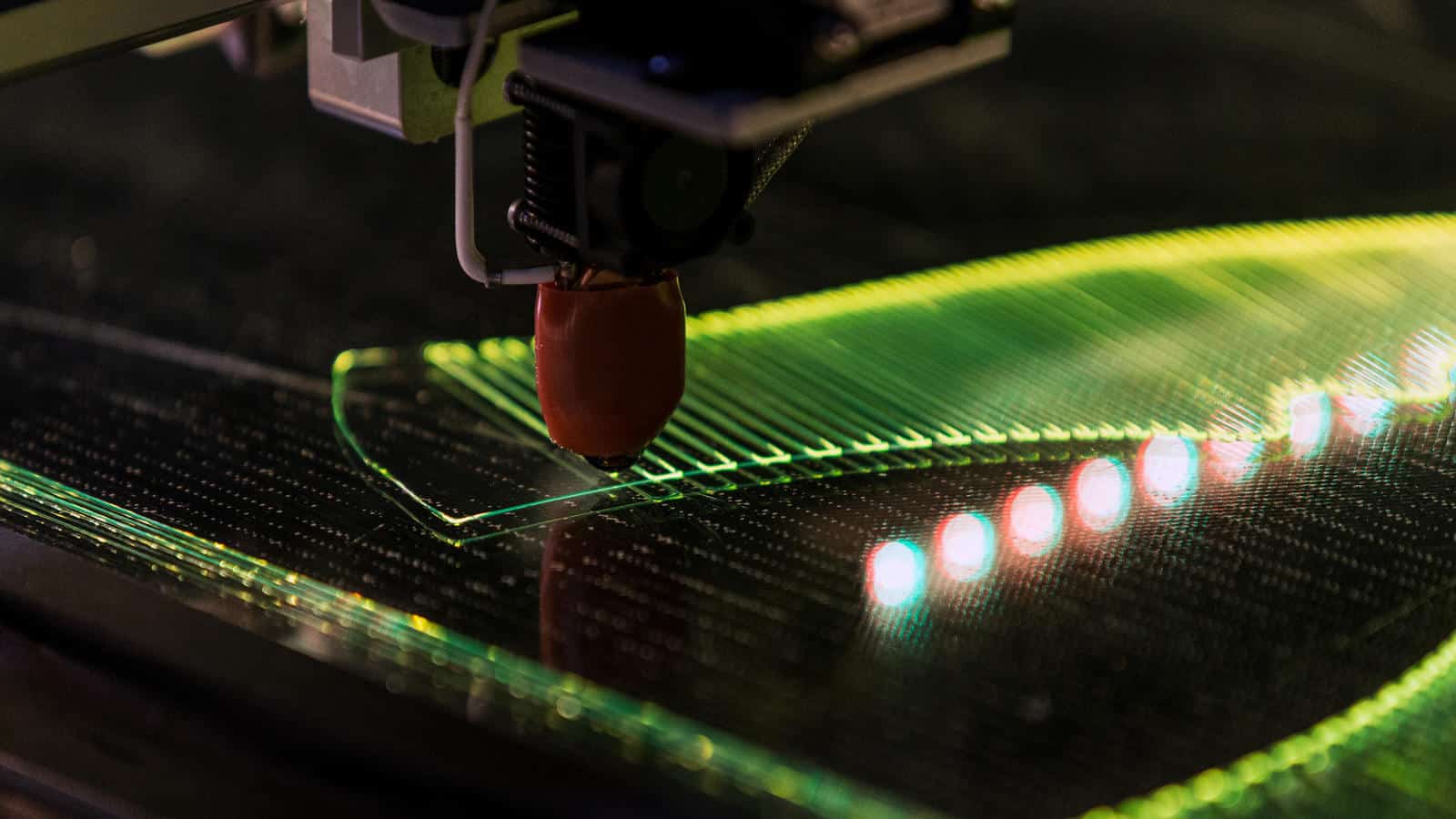

- The solid deposit modeling (SDM) technology for the Nike Flyprint uppers.

The company is now experimenting with final parts production, specifically for the labor-intensive production of uppers. Nike Flyprint is the first 3D printed textile upper in performance footwear. The Nike Flyprint uppers are produced through solid deposit modeling (SDM), a process whereby a TPU filament is unwound from a coil, melted and laid down in layers. One interesting benefit of 3D textiles that emerged over traditional 2D fabrics is the increased dynamism made possible by adding an interconnection beyond a warp and weft.

New Balance

Application(s): Limited edition midsoles, customized spike plates

Technology: SLS, SLA

Technology provider: EOS and 3D Systems for SLS, Formlabs for SLA

Material: Nylon and Duraform TPU for SLS, new durable Formlabs resins in development for SLA

Digital Data: biometric data, generative design

Boston-based New Balance was one of the first companies to experiment with 3D printing for a number of applications. First, it unveiled the Zante Generate shoe with 3D printed midsole in partnership with 3D Systems in 2016. Produced by SLS using the Duraform TPU elastomer material, the Zante Generate was the first 3D printed running sneaker to be made commercially available, however, the forty-four pairs of the Zante Generate were only available at newbalance.com and in Boston’s New Balance Experience Store with a price tag of $400. The recent introduction by New Balance of automated finishing technologies from Russell Finex in its AM lab indicates the company is working toward increased use of 3D printing as a means to automate (and possibly onshore) midsole manufacturing processes.

- The New Balance Zante Generate.

In other projects, New Balance also worked with EOS’ SLS technology, to use design-driven manufacturing for 3D printing custom spike plates for their elite athletes. Over the past couple of years, the company has been working on a separate project with Formlabs focusing on mass customization of high-performance footwear via the company’s affordable SLA systems and newly developed materials.

Under Armour

Application(s): Limited edition midsoles

Technology: SLS

Technology provider: EOS

Material: TPU

Digital Data: generative design

Under Armour, a sportswear company that has made innovation a key element of its strategy is also among the first adopters of AM for end-use part production. The company’s UA Architech is a line of shoes that features a 3D printed midsole. The first Architect line product was introduced in 2016, designed with Autodesk software and produced using EOS SLS technology. The second product, the UA Futurist, was introduced in 2017 and features 3D printed midsoles that use a TPU material developed by Lehmann&Voss&Co.

- The latest UA Futurist from Under Armour.

Priced at $300, the shoe series is Under Armour’s most expensive to date, but it also represents the company’s largest batch of shoes with 3D printed parts to date. With each shoe series, Under Armour has quadrupled production, starting with 96 pairs for the original Architech, followed by 410 for the next 3D printed shoe series. The company is now manufacturing the Futurist in a batch of a little over 2,000 pairs.

Reebok

Application(s): Mass-produced uppers

Technology: Liquid Drawing (pneumatic material extrusion via robotic arm)

Technology provider: Developed internally

Material: BASF polyurethane

Digital Data: generative design

In 2018 Reebok debuted the Liquid Floatride Run shoe, made using the same technology it introduced in its Liquid Factory. The process is essentially a 3D drawing process. The shoe is designed for distance running, cardio workouts, and comfort. In 2016 Reebok launched its Liquid Factory in Rhode Island which uses robotic arm based pneumatic extrusion process to directly manufacture shoe uppers rather than using molds.

- The Floatride Run from Reebok.

The $180 Floatride Run running shoe mixes the company’s existing Floatride Run sneaker with the Liquid Factory 3D printing technology. It has both liquid elements and “Flexweave” material. The improved shoe is 20% lighter than the original and has a few new features including liquid laces. This means the laces are 3D printed directly onto the shoe upper.

QiaoDan

Application(s): Limited edition uppers and soles

Technology: FFF

Technology provider: Raise3D

Material: TPU

Digital Data: generative design

On October 27, 2019, QianDan brought the new Future 010 shoes created by 3D printing technology to China International Fashion Week.

QiaoDan invited Tim Coppens to jointly create the series. Tim is sensitive to materials, and good at using futurism and sports elements. His designer brand TIM COPPENS combines sports and luxury. As for the 3D printed running shoes released this time, the soles and uppers are all completed with 3D printing technology.

- The Future 010 from QiaoDan.