Researchers from the Delft University of Technology in the Netherlands have discovered 3D printed biodegradable magnesium scaffolds could have promising applications in the regeneration of critical-sized bone defects.

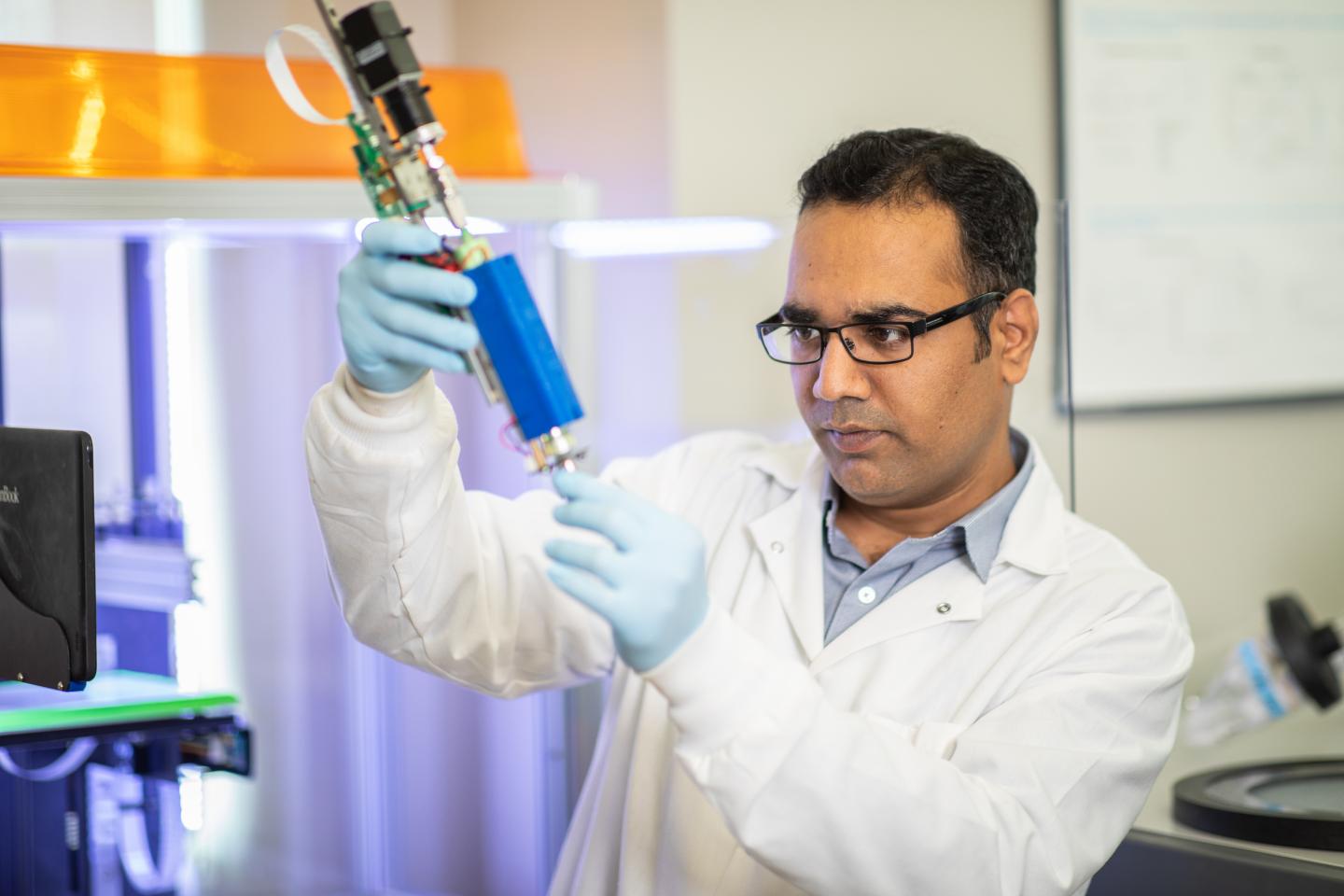

While the approach isn’t without its limitations, the researchers believe the solvent-cast 3D printed (SC-3DP) method used has ‘unprecedented possibilities’ for the fabrication of magnesium-based porous scaffolds.

“Magnesium-based material has been considered to be a new class of promising biomaterials in orthopedic applications because it can degrade gradually in the body, and at the same time, stimulate bone regeneration and help the healing process of bone defects,” said Professor Amir Zadpoor of the biomechanical department at Delft, and one of the researchers involved in the study. “Therefore, fabricating porous magnesium implants is attracting more and more interest.”

Biomaterials for orthopedic applications

Using additive manufacturing to fabricate magnesium-based materials has recently started in a small number of university research groups, with selective laser melting (SLM) one of the commonly chosen methods. The success of using this method is, however, rather limited as a result of challenges surrounding safety in operation due to magnesium’s high flammability, as well as undesirable compositional variations in the final produced parts.

Recently, some attempts have been made to develop powder bed inkjet 3D printing and fused filament fabrication (FFF) techniques, followed by a sintering step, as alternatives to SLM. However, utilizing these techniques for the fabrication of topologically ordered porous Mg scaffolds has not yet been reported.

“Due to high flammability of magnesium powder under high laser energy, safety in operation is the primary challenge encountered during fabrication of magnesium scaffolds,” Zadpoor explained. “Utilizing higher laser power also increases the chance of magnesium evaporation and creates significant thermal gradients during SLM, making the manufacturing process costly.”

Employing an alternative method, materials researchers at ETH Zurich, Switzerland, developed an additive manufacturing-based procedure to make magnesium scaffolds with regular porosity, using a 3D printed salt template. Although this work was only a proof of concept when announced, researchers involved in the study believe these magnesium scaffolds have the potential for creating bioresorbable bone implants.

Aside from magnesium-based research, there have been some other real-world applications of 3D printed scaffolds. Last year, scientists from the UK’s Animal Health Trust (AHT) and the University of East Anglia (UEA) used 3D printed BendLay Polycarbonate filament scaffolds to support bone regeneration in horses. These 3D printed scaffolds were used to enable successful osteoblast, demonstrating the feasibility of generating 3D bone constructs through a process called cell seeding.

Most recently, scientists in the Department of Biomedical Engineering at Texas A&M University have been making headway in the field of 3D bioprinting functional tissues, by conducting research into the development of new biomaterials. Early indications in this area suggest additive manufacturing could be feasibly used to treat defects and conditions such as arthritis, bone fractures, dental infections, and craniofacial defects.

Other advancements in this particular field have come from Rice University and the University of Maryland (UMD), where scientists outlined a new proof-of-concept for 3D printing artificial bone tissue to help repair damage related to arthritis and sporting accidents.

“3D printing has the potential to partially replace conventional manufacturing in the future, especially in customized or patient-specific implants and complex porous manufacturing,” added Jie Zhou of the biomechanical department at Delft, and one of the researchers involved in the Solvent-Cast 3D printing of magnesium scaffolds study. “3D printing offers many more possibilities for clinical treatment strategy and it will help to significantly reduce manufacturing cost in terms of saving original materials and shortening lead time.”

The SC-3DP study

During the study, the researchers proposed a room-temperature extrusion-based additive manufacturing method, namely SC-3DP, to fabricate topologically ordered, porous magnesium scaffolds, composed of three steps.

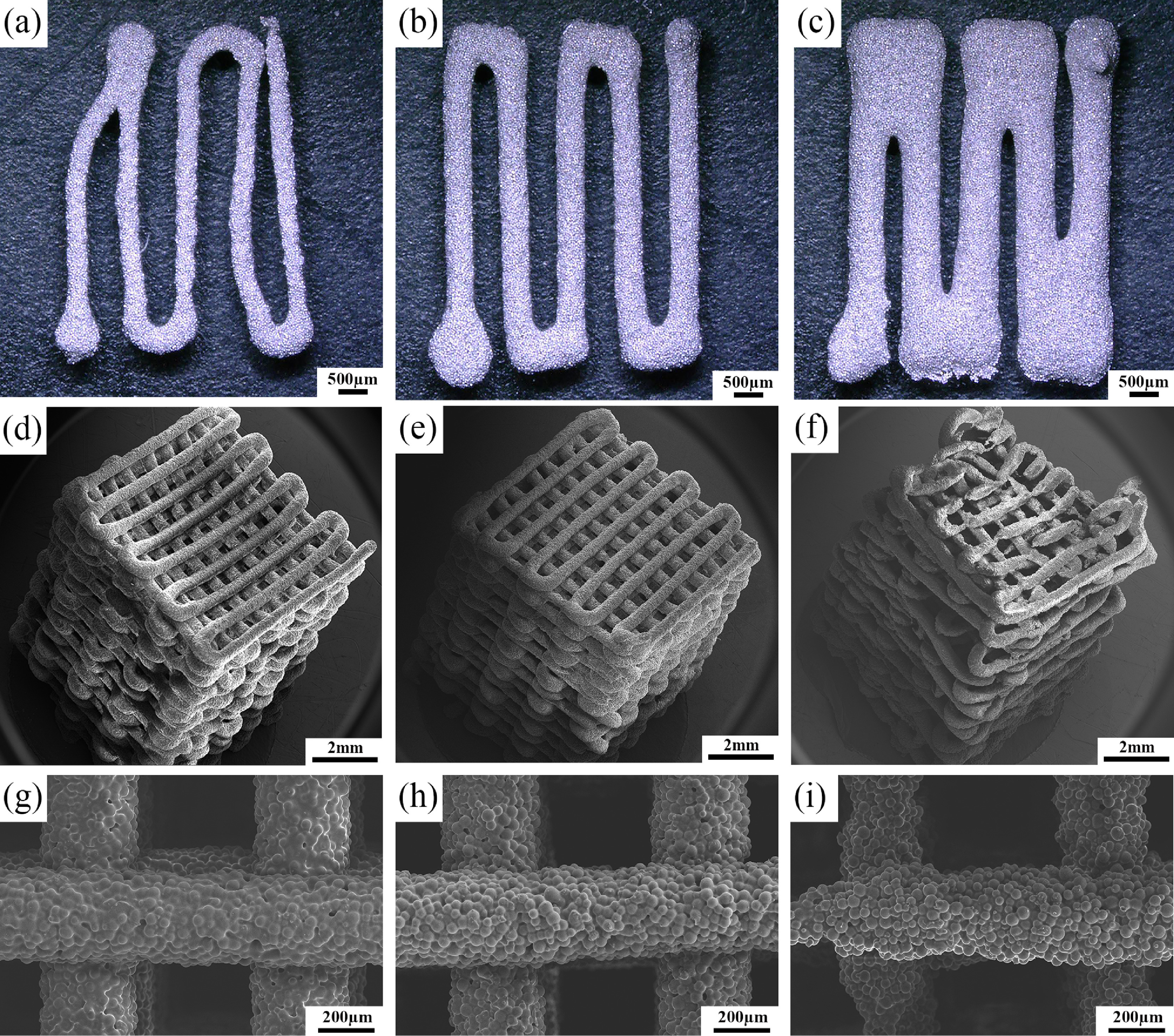

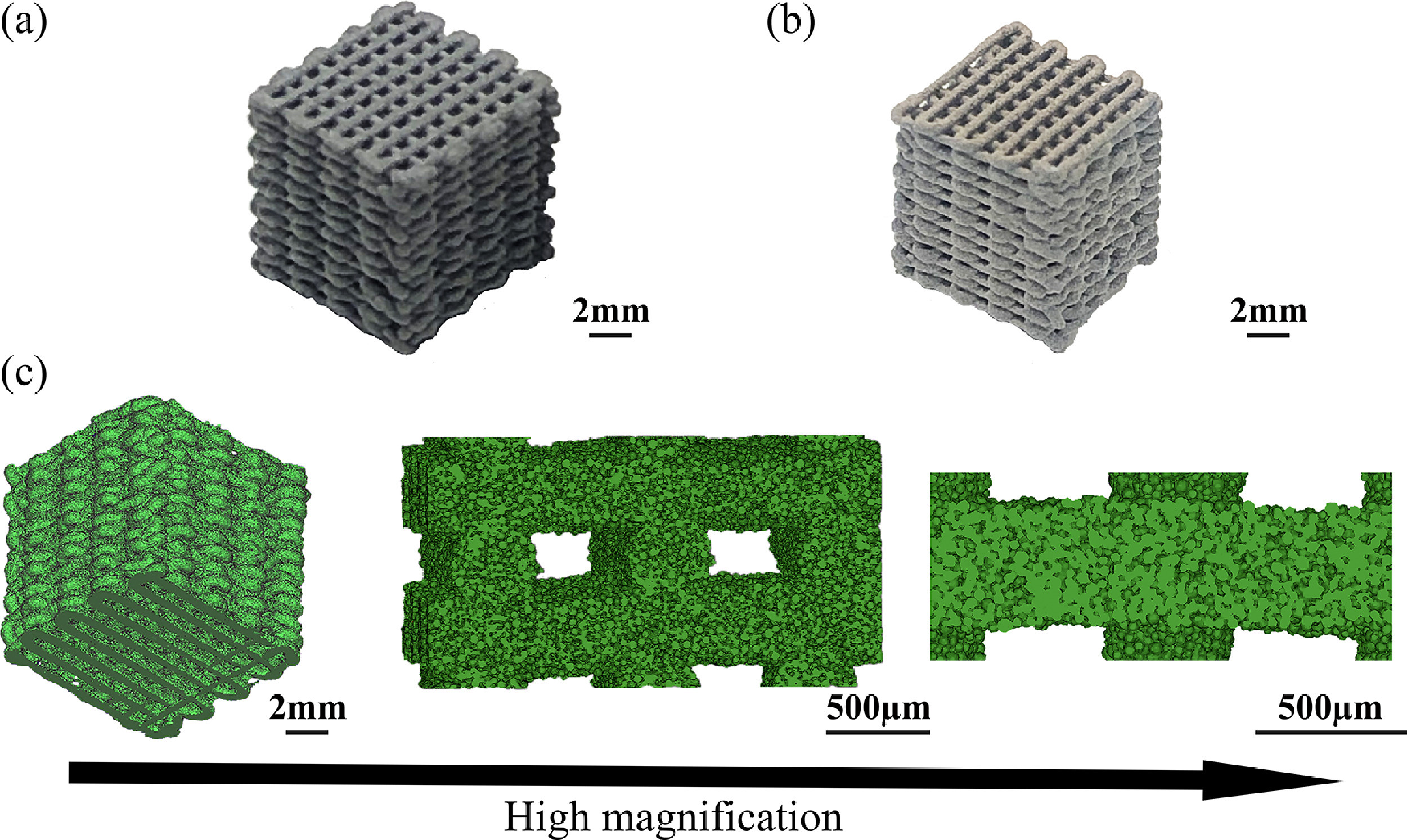

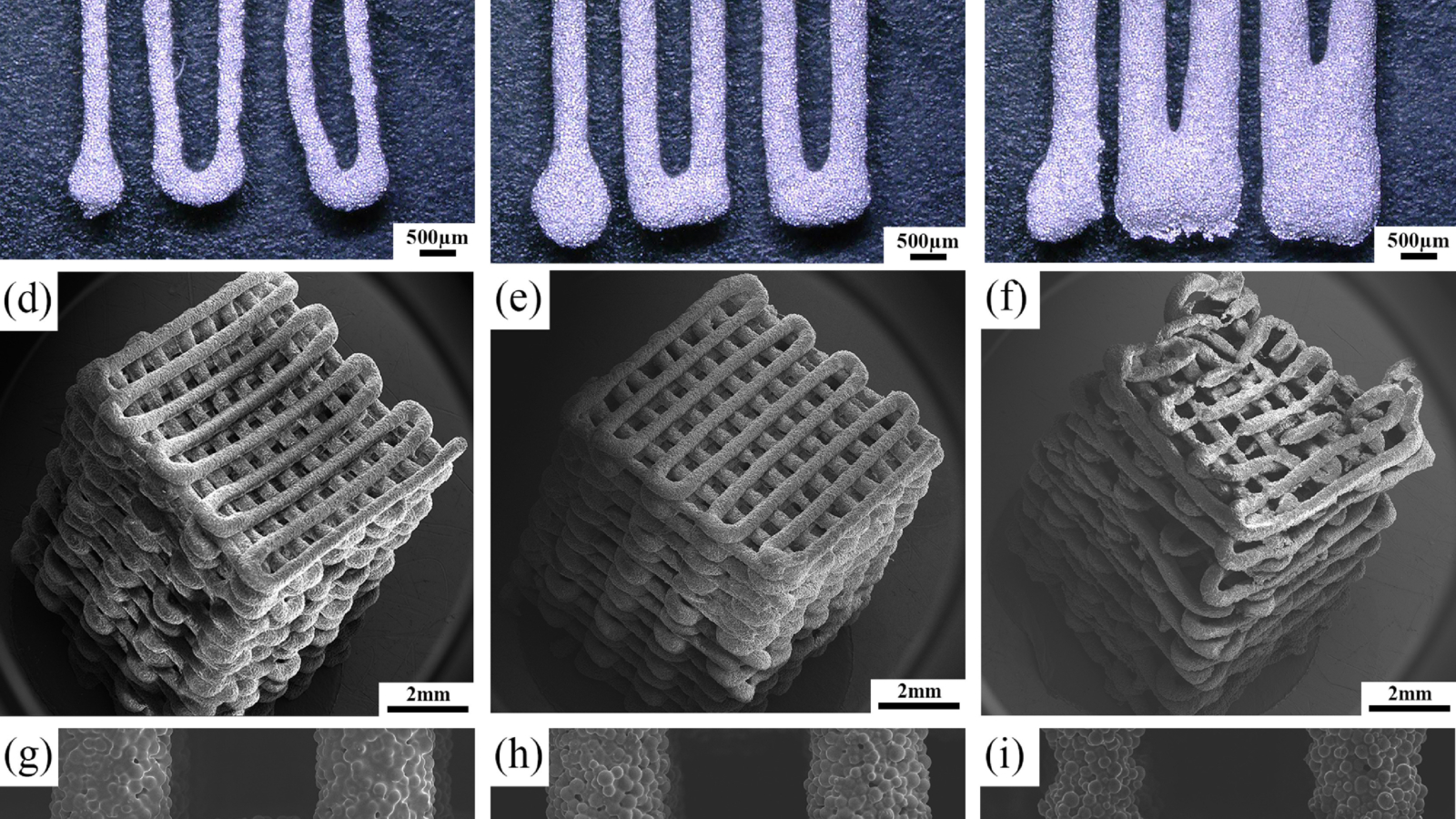

The first stage involved preparing a magnesium powder loaded ink with the desired rheological properties, which refers to the way in which materials deform or flow in response to applied stresses. The ink, together with a binder system composed of a polymer or volatile solvent, was then extruded through a nozzle and printed into scaffolds with 0°/90°/0° layers. Finally, a debinding and sintering process took place in order to remove the binder in the ink and bond the magnesium powder particles through applying a liquid-phase sintering strategy.

Rheological analysis of the prepared inks, with 54%, 58%, and 62% volume of magnesium powder loading, took place to reveal the scaffold’s viscoelastic properties. Viscoelasticity refers to the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation.

Manufacturing on Demand

Thermal gravimetric analysis (TGA), Fourier transform infrared spectroscopy (FTIR), carbon and sulfur analysis, and scanning electron microscopy (SEM) of the scaffolds also took place, indicating the possibility of debinding and sintering in one single step.

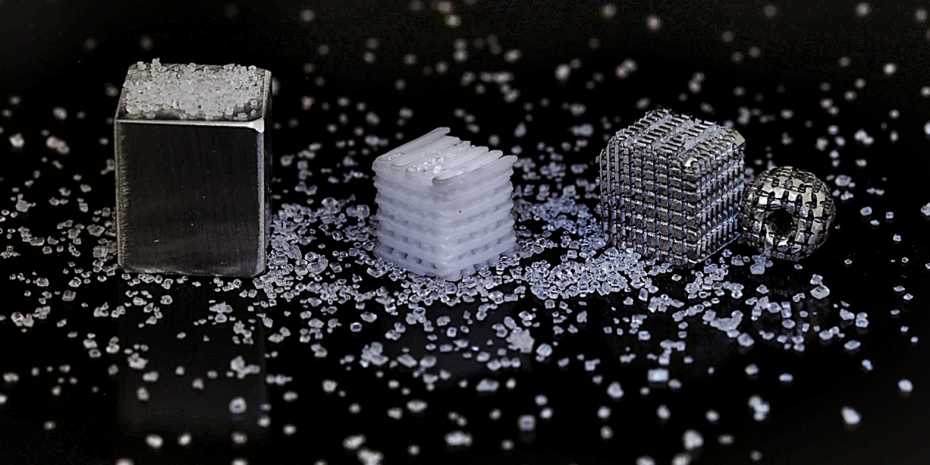

The end-product scaffolds had high porosity, containing hierarchical and interconnected pores. According to the researchers, this study demonstrated for the first time that the SC-3DP technique could be used to successfully fabricate magnesium-based porous scaffolds with the potential to be used as a bone-substituting material.

Significance of the findings

The regeneration of critical-sized bone defects has remained a clinical challenge in modern medicine and usually necessitates bone grafting materials. Previously, scientists have 3D printed implants using traditional materials such as bioinert titanium and PEKK. However, these metals often require a second surgery for implant removal. Additionally, available grafts and many existing synthetic biomaterials designed for these applications do not meet all of the clinical requirements, meaning the development of a new generation of suitable bone substitutes is desired.

In recent years, magnesium-based biodegradable metals have been considered promising for these kinds of orthopedic applications, as they can be altered to possess both mechanical and biological aspects needed for bone defect regeneration. Advances in additive manufacturing offer a greater degree of design and manufacturing flexibility and efficiency over traditional techniques to fabricate porous magnesium scaffolds, and therefore make it possible to produce fully interconnected porous structures with precisely controlled topological parameters.

The SC-3DP method, in particular, has great potential to overcome the material, technical, and structural limitations of other AM techniques currently applied to fabricate porous magnesium scaffolds. According to the outcomes of the study, SC-3DP offers multiple advantages such as 3D printing at ambient conditions, easy adjustment of the components of the ink, low investment in equipment, and the potential to fabricate complex structures with hierarchical pores and desired alloy compositions.

“Employing ink extrusion-based additive manufacturing technique to manufacture biodegradable magnesium scaffold avoids utilizing heat source, which eliminates the limitation of PBF,” said Jiahui Dong, one of the researchers of the study from the biomechanical department at Delft. “The flexibility in fabricating magnesium-based metals or composites with desired components and composition also makes this method attractive and advantageous.”

The SC-3DP method has also been demonstrated to be feasible in the additive manufacture of steel, iron, titanium-based, and nickel-based micro-trusses.

Future research in this field

Essentially, the results obtained from this study provide a new way of fabricating biodegradable magnesium scaffolds appropriate for orthopedic applications. Although, there is still further research to be carried out in this field, according to Zadpoor.

“We will continue further research on investigating the performance of the additive manufactured fabricated magnesium scaffolds,” he concluded. “In the next step, both in vitro and in vivo performances of the magnesium scaffolds would need to be evaluated in terms of biomechanical stability, biodegradability, and osteogenic ability.”

Further details of the study can be found in the article titled ”, published in the Acta Biomaterialia journal. The article is co-authored by J. Dong, Y. Li, P. Lin, M.A. Leeflang, S. van Asperen, K. Yu, N. Tümer, B. Norder, A.A. Zadpoor, and J. Zhou.

* This article is reprinted from 3D Printing Industry. If you are involved in infringement, please contact us to delete it.

Author: Hayley Everett

Leave A Comment