A few years ago, Syqe Medical, an Israeli drug delivery company, manufactured a 3D printed medical cannabis inhaler, which can control the dose of medicinal cannabis and is, therefore, a healthier choice. Now, the company is turning to XJet Ltd., another Israeli company, to use its NanoParticle Jetting (NPJ) technology to help 3D print continuous high-temperature parts, which has been applied in the medical and dental fields.

The company’s flagship product Selective-Dose medical inhaler has high accuracy, so it is safe and effective in treating patients. This user-friendly device uses cartridges equipped with pre-filled pharmaceutical VaporChips to deliver drugs at very customized and precise levels, so users can improve their quality of life by achieving the best balance between symptom relief and press release called “adverse events”.

The Syqe Medical website states: “Using its breakthrough technology, Syqe aims to relieve the suffering of as many patients as possible in the fastest way.”

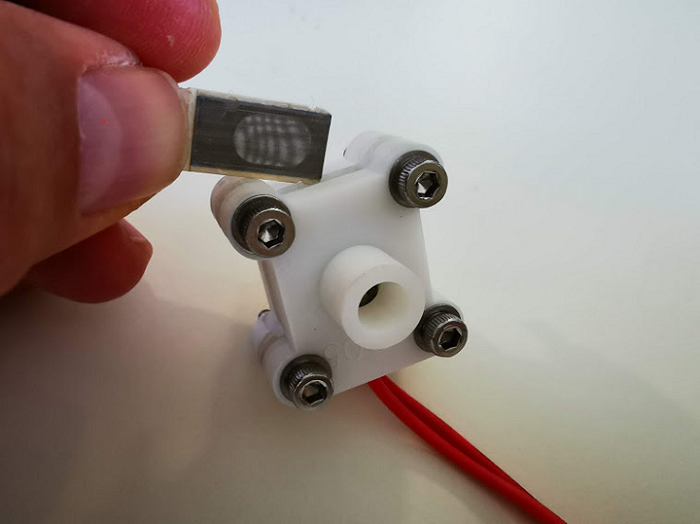

Syqe Medical is studying the use of PEEK materials with traditional manufacturing processes because it needs to establish an accurate high-temperature electrical insulation test facility to develop its products. But the company found that most of the design processes are not enough because they require a lot of adjustments, leading to soaring costs and delivery times, and it is difficult for them to find durable heat-resistant materials.

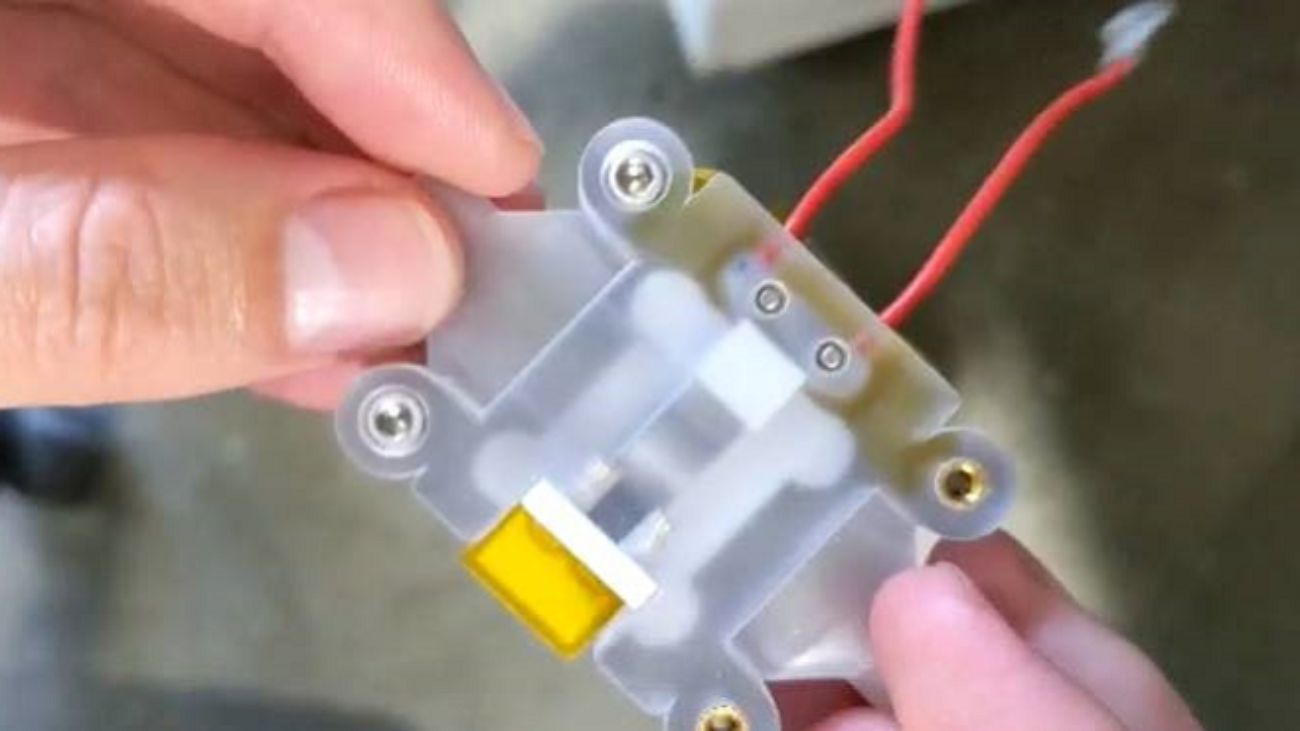

“Realizing that we need another solution, we turned to XJet. We have extensive experience in additive manufacturing technology. Although polymer materials do not have the heat resistance we need, the high temperature resistance of XJet ceramic materials is even higher than Our requirements, and they are electrically insulated. Small design adjustments are very easy, the results are accurate and repeatable, so we can achieve the best accuracy, and the delivery time is very fast. There are defects in at least one aspect in all other options Where, XJet provides the perfect solution.” Syqe Medical Product Manager Itay Kurgan said.

According to XJet, its patented NPJ technology and Carmel 1400 3D printer can easily create parts with ultra-fine coatings with high precision, smooth surfaces and extremely fine details… This is what Syqe Medical does needs.

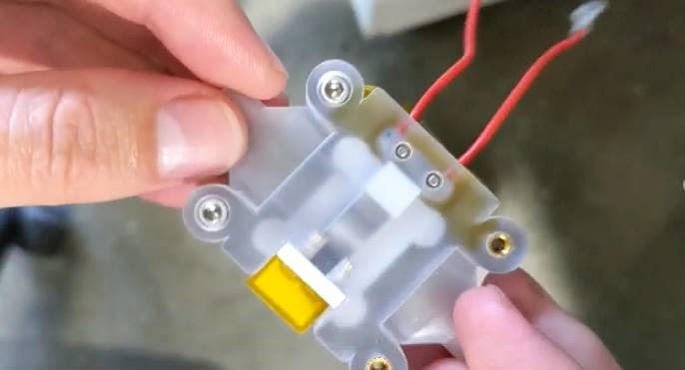

Medical’s new test facility

XJet CBO Dror Danai said: “Syqe Medical is changing the life of patient care, so we are very happy to see them benefit from the unique features of XJet.” Ceramics have some very valuable material properties, but due to the Difficult, it may be difficult to use them. XJet has all the advantages of ceramic materials, high accuracy, high precision, but without the difficulties of traditional manufacturing.”

Last month, Syqe Medical purchased the new Stratasys J55 to optimize and speed up its product design process by 3D printing multiple elements of its inhaler prototype, including housing, chassis, and spring. Now, with the investment in XJet ceramic NPJ 3D printing, this pharmaceutical technology company seems to cover all of its bases.

Leave A Comment